Koster's Miniature Railroad Supplies, Inc

Koster’s Miniature Railroad Supplies was a live steam equipment supplier founded and operated by William C. "Bill" Koster in 1970.

The product line was acquired by Cannonball Enterprises Ltd on June 1983, as announced by a full page advertisement in Live Steam Magazine, July 1983.

History

- "Behind the Scenes at Kosters", by Bill Koster, 2014 (PDF)

- "Behind the Scenes at Kosters" Jacket Cover, by Bill Koster, 2014 (PDF)

- Bill Koster's Wandering Locomotive Book - PowerPoint Slides

Koster’s Miniature Railroad Supplies was started by Wilfred C. “Bill” Koster in 1970. Bill had been in trains all of his life. An early occupation was as a Lionel & American Flyer repairman in 1949-50. He built and operated a number of model railroads. His main occupation was as an equipment maintenance person for AT&T. There he worked on microwave, high power troposcatter systems and undersea cable. Entering the 1-1/2" scale field he found little available in the late 1960’s. He decided to start building from scratch.

About the same time, Ed Pruitt built his Flat River & Southern Railroad in North Palm Beach, FL. Bill ended up making a number of items for Ed. He realized there might be others who would want his products and started advertising in Live Steam magazine.

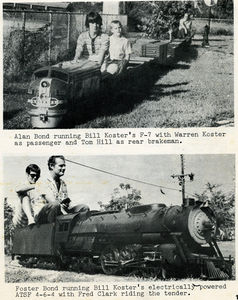

Bill’s first locomotive in 1-1/2" scale was a 4 wheel switcher in 1968. By 1970 he had built his first GP-7 and by 1971, a pair of electrically powered 4-6-4 steam locomotives. By 1972 an F-7 was built and was followed with various other types of locomotives and rolling stock. Though an exact record was not kept, Bill’s estimate is that he produced about 40 locomotives and over 100 freight and passenger cars. Bill’s preference was battery powered locomotives, instead of using gasoline engines.

Bill made patterns for a number of castings including wheels, drivers, tender trucks, trailing truck, domes and smokebox front for the 4-6-4. He also made freight trucks and diesel trucks and detail parts such as roof vents.

In 1978 Bill and co-author Tom Hill published a book, Large Scale Model Railroading to assist newcomers in the hobby.

No project was too much for Bill to consider. One item he made was a half size traffic signal, for use by a school to teach handicapped individuals when to cross the street. Another project was to fabricate and install track for a local customer.

His locomotives and cars were all steel, for lasting durability. He used a local sheet metal shop to do much of the cutting and forming. For help in the shop he hired a number of high school students.

Due to pressures at home, with two teenaged children, he finally decided to sell his business in 1982. Cannonball and later MDM Locomotive Works were the buyers of his company.

With 3 acres of mountain land in North Carolina Bill decided to build a 7-1/2" gauge railway. Bill & neighbor Bob Fink did over 90% of the construction. They started construction in 1987 and had the golden screw ceremony in 1997. The Blue Ridge Summit is point-to-point, ½ mile in length with a 50 foot difference in elevation between Summit and Whistlestop. Five passing tracks were installed for multiple train operation. The property and railroad were sold to another railroader who intends to keep it operating.

In 1989 Bill heard about the restoration of Sandley Light Railway Equipment, a 15” gauge factory and railway, located in Wisconsin Dells, WI. He and wife Alice spent over a dozen summers doing everything from being President, Gift Shop Manager, Conductor, Gandy Dancer and many other projects.

Now in his 80’s (2013), Bill still stays active in the hobby, with about 4,000 feet of track on his property in Florida. He has also written a number of articles for Modeltech and Live Steam and Outdoor Railroading.

Growth

Bill Koster wrote the following which appeared in Live Steam Magazine, October 1973:

- Our business was founded as a hobby. As such, prices were established that did not reflect true manufacturing costs but rather what I would expect to pay as a customer. While the business was small and I did all or most of the work, the prices charged for machining did not matter very much. I enjoyed the work and it was a sideline so it didn't matter that I paid myself a very meager wage. As the business grew and I had to hire employees to do the machining, it became apparent that we were not charging enough for the machining to pay employees' salaries. Time studies had to be made and prices adjusted accordingly. A recent order for parts that have a catalog machining price of $23.60 (up from $17.40 last year) required 9 hours of my best employee's time at $2.62 per hour. Obviously the price for these parts will have to be raised much more.

First GP-7

Chris Schieck wrote, May 2014:

- I looked over the IBLS website and saw a piece on Bill Koster and his first GP-7 in 1970. I own and operate that same engine (I replaced its motors and controls). That first GP-7 had no doors or louvers on the long hood as his later Geeps did. I joined the BLS back in the Carl Purinton days.

- I contacted Bill Koster regarding mechanical and electrical details of the engine after I had purchased it from an estate in Indiana. I later corresponded and spoke with him at a steam meet in Florida. Bill told a story of how the engine was damaged during his visit to the west coast, repaired and sold while he was still in Oregon. It wound up spending most of its life out west (thus the SP black widow paint scheme) before being sold to a fellow in Indianapolis who ran it on tracks in Michigan and probably elsewhere. I believe the damage occurred at the PNWLS Shady Dell track near Portland, OR. Bill's story was particularly interesting, as I had been an associate member of the PNWLS the late 1970s and 1980s. Several pleasant sessions were spent with PNWLS president Harry Harvey and others in the club during my several business trips to Oregon and Washington. Small world! Great hobby!

Wheel Flange Depth

Bill Koster posted the following message on the Yahoo Live Diesel group, 20 July 2013:

- When I had my business I had a customer who wanted to make a commercial operation out of his train. To help prevent derailments we made the flanges 5/16" deep, instead of the IBLS 3/16". I can't tell you if that helped as he stored the equipment in a metal shed and then Hurricane Andrew came along. The club at Tradewinds Park in Ft. Lauderdale got the equipment and were they surprised when they saw the flanges!

- As to problems with the 3/16" flange - I can report that is what I used on the Blue Ridge Summit. We had curves as sharp as 20' radius and seldom had a derailment.

Tidbits from Chaski

From George Becker, 17 August 2011:

- Back in the early '80s, I bought 24V Westinghouse motors from Koster (now CannonBall and further divided into MDM Locomotive Works) that used to be surplus aircraft engine starters rewound for use in his 1.5" engines. In Koster's design, the motors fit in-between the wheels and against the axle.

Worked in Steel

Question: I've been wondering, how did you make those beautiful F-7 noses on your models? Is that steel, aluminum, fiberglass?

Answer: I carved a wood block and we cut 16 ga. steel to pieces (like an orange peel) and formed them over the block, welded them together, ground it down to make it rounded, then added weld to where we struck daylight. It took several hours to get a good shape. Everything I did was in steel. Like the late Lee Wright said "if it ain't steel, it ain't real".

For a similar techniques see:

- Dan's Loco Works Bobtail Observation construction.

- "Building EMC E6 ABA units in 1.6 scale", Facebook

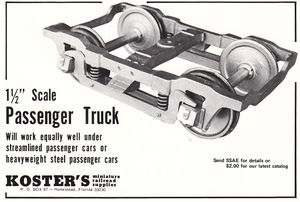

Koster's Miniature Railroad Supplies, Inc advertisement from Live Steam Magazine, August 1976.

Catalogs

Bill Koster graciously granted permission for the IBLS to publish his catalogs.

Gears vs Sprockets

- When I produced locomotives I had to contend with motors that topped out at 7,500 rpm. I still prefer enclosed gearboxes for smooth trouble free operation. My feeling - if it is good enough for the full size, it is good enough for our size. -- Bill Koster

SOO Line Switcher

Steve Haupert posted on Yahoo Live Diesel Group, November 2016:

- The engine was bought by my brother almost 40 year ago from Kosters, and drove it from the shop in Forida back to his home in Wisconsin. His son Dave and I build a 300-plus foot 1.5 inch scale railway, and it ran perfectly for many years. My brother died about 2 years ago and, when I heard they were selling his property, I got permission from my family out there to bring the loco, cars (all homemade) and track back to my home in Pennsylvania.

Bill Koster replied:

- I will say, for a 40 year old locomotive, it looks good! I see it has had some modifications, such as the air horns. I believe I supplied it with a car horn inside the body.

- Your locomotive was one of a kind. I am thinking it had one motor to drive the front truck, but I could be wrong. I am also thinking that it was chain drive connected to the motor. The motors were war surplus, meaning they are now 70 years old.

- Apparently, from what you have said, I used 2 of our "standard" motors and gearboxes. At the time all I could find were those motors, .55 HP, 7,500 RPM. They were used in aircraft, to rotate the gun housings. They have 4 wires, two for the field and two for the armature. We wired the motors through their reversing relays and I believe a circuit breaker. This is why they are separate. If one circuit fails, you still have the other circuit, so one motor could still run. Since the motors are between the wheels, you must remove a wheel to get to the motor. The wheels are either pinned or have a set screw holding them on the axle.

- Those are Bethlehem sideframes. I bought my first 7 1/2 inch equipment from them in a visit to Bethlehem in 1963.

- I delivered the locomotive to your brother on one of my crazy trips. Saturday I set up in Columbia, TN. Sunday morning we stopped by Illinois Live Steamers in Chicago, Sunday afternoon Waukesha, 7 PM the ferry to MI, Monday at Village Press (Live Steam Magazine), then to Cadillac, St. Clair Shores, MI and on to Indiana before we called it a day!

- An interesting note. I wasn't sure if I knew that much about motors before I started using them so I consulted with someone at the Livesteam meet. Turns out he was the designer who designed the traction motors for the Alco PAs. So I enjoyed discussing motors with him. He later visited my railroad in North Carolina and was impressed with the pulling power of my locomotives.

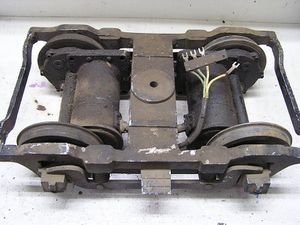

Ken Roeh posted photos of Koster's Powered Switcher Trucks on Chaski.org, 2018.

Gallery

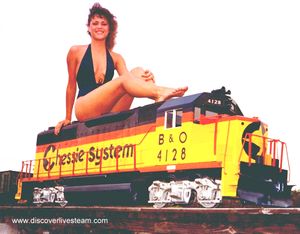

Koster GP7 1.5" scale, 7.5" gauge locomotive, all steel body held on by 2 nuts, removable in one piece. Four deep cycle batteries in series power a Curtis controller, (24 vdc) and are accessible through roof hatches for easy maintenance. Hand held control consists of master switch, horn button, bell button, reversing switch, light switch and run 1-8 throttle. Each axle is powered by 7500 rpm motors with gear boxes which move this locomotive at 15 mph clocked by radar. Approx. weight is 600 lbs. Also included are extra motors, wheels, axles gearboxes, and brake castings. Trucks are sprung and made out of cast aluminum. Built by Bill Koster about 20 years ago. From DiscoverLiveSteam.com.

Koster's SD-40 Number 3455 on its way to be delivered to Seymour F. Johnson in California, posing here at Terry McGrath's Annetta Valley & Western Railroad just outside of Fort Worth, Texas. Photo from 8mm movie taken by Bill Koster, mid to late 1970s.

Bill Koster's former residence in Homestead, Florida, which housed Koster's Miniature Railroad Supplies, Inc in the basement. Photo by Jeff Smith, 25 May 2015.

An AAR Truck kit by Koster's Miniature Railroad Supplies, Inc, posted for sale on DiscoverLiveSteam, June 2015.

The AAR Truck kit by Koster's Miniature Railroad Supplies, Inc included Tol-O-Matic gear boxes.

Kenny Rhodes at the throttle of a Koster's Miniature Railroad Supply diesel at the Annetta Valley & Western Railroad. Photo by Tom Stamey.

References

- "#308 for the MSRy (The Toybox Caboose)", DiscoverLiveSteam.com

- "Let's Build a Caboose", build based on Toybox Caboose, Leo Myers, Live Steam Magazine, March 1973

- "Live Steam Supplier: Ten Year Milestone", Joe D. Rice, Live Steam Magazine, May 1980, Bill Koster's Miniature Railroad Supplies

- "Behind the Scenes at Kosters", Chaski.org