Charles Field Track Panel Jig: Difference between revisions

(→Use) |

(→Use) |

||

| Line 56: | Line 56: | ||

<gallery widths=300px heights=300px perrow=2> | <gallery widths=300px heights=300px perrow=2> | ||

File:2020-11-28 | File:2020-11-28 12.10.50.jpg|Step 1: Place ties on the jig with straight rails on top. Start track screws to hold things in place. | ||

File:2020-11-28 12.16.06.jpg|Step 2: Clamp the third tie from each end in place. Use two screws to fasten a rail in the middle of the tie plate. Start at one of the clamped ties. Tighten the screws on each tie, making sure the tie is touching the tie stop on the jig. | File:2020-11-28 12.16.06.jpg|Step 2: Clamp the third tie from each end in place. Use two screws to fasten a rail in the middle of the tie plate. Start at one of the clamped ties. Tighten the screws on each tie, making sure the tie is touching the tie stop on the jig. | ||

</gallery> | </gallery> | ||

Revision as of 22:47, 1 December 2020

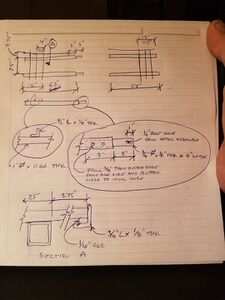

In March, 2020, Charles Field posted on Facebook about a Track Panel Jig that he built. This was the second one of these jigs he constructed. It is light weight and disassembles into two parts for easy storage. It will work for constructing both straight and curved track panels of 10 foot length.

This article presents Charles' original drawings and photos, along with a version modified for Texas Standard Tie Spacing.

The Original

These photos were provided by Charles Field and come from his original Facebook posting. Used with permission.

This design specifies 4 inch spacing from tie to tie.

Texas Tie Spacing

This design is modified to use the Texas Standard Tie Spacing of 5.5 inches from tie to tie.

- Track Panel Jig Bill of Materials (PDF)

- 200 Assembly Drawing (PDF)

- 100 Main Support Beam (PDF)

- 110 Main Support Joint (PDF)

- 120 Tie Stop (PDF)

- 130 Tie Retainer (PDF)

- 130 Sagitta Rule for 10 Foot Rail (PDF)

Use

Daris A Nevil wrote:

- The Charles Field Track Panel Jig can be used to construct straight as well as curved track panels (see Sagitta Rule). I use ties produced by Enterprise Plastics Inc, as it makes panel assembly super easy.

- Here is how I build curved panels with 50 foot radius.

Step 1: Ties are placed in the jig with pre-curved aluminum rail on top.

- The procedure for building straight panels is even simpler.