Boiler Construction

Soft Solder vs Bronze Welding

by L.B.S.C.

The Live Steamer, May-June 1950

Question: Is a boiler safe to use if it is sweated at the joints, tubes and stays with soft solder?

Answer: Whilst a boiler can be safe to use with riveted and soldered joints, it rapidly deteriorates and eventually leaks. The reason is that the solder gets hard, just like the whitemetal in the big ends of an automobile engine, and presently cracks under the stresses of continued expansion and contraction. Also, a riveted boiler can never be as strong as a brazed or bronze-welded one, for this reason: The perforations where the rivets go thru weaken the plates just like the perforations in a sheet of postage stamps; and given sufficient stress, the plate would tear along the line of holes, just like you can tear the sheet of stamps. This was the cause of several boiler explosions in the early days of steam locomotives.

It is many years ago that I abandoned riveting, except for just a few needed to hold the parts of a boiler together while bronze-welding. In my experience, the most satisfactory construction is all bronze-welded seams, and silver-soldered flues. Thinner metal can be used, with a greater factor of safety, than if the joints are riveted and sweated.

Smaller Loco, Lower Pressure

Karl Friedrich (Note: original article spelled last name as "Friedrick")

2039 5th Ave

Pittsburgh 19, PA

The North American Live Steamer, Volume 1 Number 4

Just a few words about steam pressures in small engines. That is, engines with boilers 5 inches or less in diameter. In my opinion, a lot of the fellows are using pressures entirely too high. 100 to 125 pounds is much more than can be used efficiently on the average small locomotive. Most of these little fellows can get along quite nicely on 60 to 75 pounds, and even less if superheated. In my experience and observation, I have come to the conclusion that a superheated job at 60 pounds will do about as well and maybe better than a wet steamer at 90 or 100. Also, the 100+ pressures are liable to cause many little leaks to develop around glands and fittings. The only thing to be gained by higher pressures is that they tend to cancel out defects in workmanship, etc., by sheer brute force.

Tube Sheet

From "Reaming vs. Drilling Holes In Tube Sheets", Chaski.org:

- Question: I am working on building a steel boiler with copper tubes. The tubes will be 1/2 inch type K copper, with an O.D. of 0.625 inch. If I use a 16 mm drill for the tube sheets (16mm = 0.6299 inch) this would yield about 0.005 inch oversize on the holes. Some clearance is a good thing, although I recognize that a drill is not as precise as a reamer. A drill would also give a somewhat rougher finish than a reamer, which may (or may not) be desirable to key in the tubes after rolling (?) I would appreciate any comments on this.

- Answer: Welding of the tube sheet is likely to distort the drilled holes in proximity of the weld(s). Also, drills have a nasty habit of cutting less than round holes, which may or may not be straight, or on size. While reamers, too, can yield similar errors, they're reduced drastically, so the end result would be more reliable, plus any distortion of hole diameter due to welding would be eliminated.

- If you must drill and not ream, don't drill the hole with the target diameter drill. Drill undersized, then open the hole with the proper sized drill after the boiler has been welded. That's not as good as reaming (or boring), but it will yield more consistent hole size, and likely a better surface finish.

Expansion

As a boiler heats up it will expand in all directions, but most notably in the horizontal or length-wise direction. If the boiler is firmly attached at both ends (the smokebox at the front and the frame at the rear) then the boiler most likely will cause stresses in the frame which may throw the running gear out of alignment.

There are two possible ways to solve this problem.

Solution 1: Allow for expansion at the smokebox.

- I have used two boilers made by the late Ray Pennell for Allen Moguls. I asked him to turn down the smokebox end of the boilers to around half the thickness of the boiler shell for about five eighths of an inch. Then, when I built the smoke box, I bored out said smokebox so that it would slip over the turned down portion. When we mounted the boiler onto the frame as per the print, we slid the boiler into the smokebox and left about an eighth inch gap before the boiler bottomed out. When everything was in place, we tack welded the boiler to the rear mounts. The idea being, when the boiler heated up and expanded, it would slide into the smoke box. That was our expansion joint. one engine is 18 years old, the other is 15 years old. No problems have cropped up with this arrangement.

- My Allen Mogul, which was put on the road back 1982, used the same design. I had a heck of a time wrestling that chunk of pipe onto the lathe so that I could do the turn down process. It still works to this day. That engine was the product of the Wilson Locomotive Works Shop.

Solution 2: Allow for expansion where the firebox end of the boiler attaches to the frame. Most prototype locomotives use sliding boiler mounts to allow for expansion.

Another style of sliding boiler mounting bracket from the Super Simplex 0-6-0. The boiler mounting brackets sit on the top edge of the locomotive frames. There is another bracket that sits on top of the boiler bracket. This bracket is fastened to the locomotive frames. This creates a joint that can slide along the top of the frame as the boiler gets a little longer when it heats up, yet, the boiler is locked to the frame.

From Model Steam Locomotives by Henry Greenly:

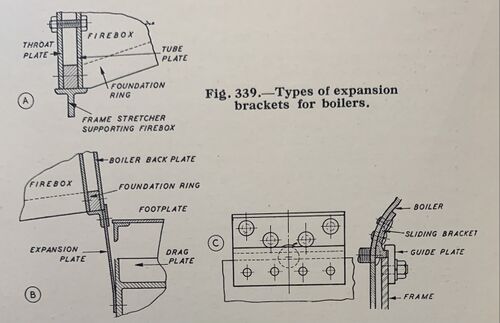

- Boilers are usually firmly fixed to the frames at the smokebox end, but at the back some scheme must be devised to hold the firebox down to the frames and at the same time permit movement to allow for thermal expansion. The usual method is to fit an angle to the firebox side which rests on the top edge of the frames and to bolt another angle to the latter and lapping over the boiler angle. The design and location of expansion brackets supporting the boiler will depend upon the type of firebox employed. For a boiler with a wide firebox, three-point suspension can be provided at the base of the foundation ring. The front of the ring is supported on a shoe resting on the main frame stretcher, and the rear can be supported on two brackets fixed to the drag plate. (See image)

- A boiler with a narrow firebox is supported on a pair of expansion brackets fixed to the main frames and, if necessary for strength, to an additional bracket fixed to the drag plate. The longitudinal thermal expansion for the boiler of a 7-1/4 inch gauge Pacific type locomotive is from 1/8 to 3/16 inch according to the temperature of the steam. Provision must also be made for transverse expansion of the firebox in all cases.

Boiling mechanics

There are three types of boiling.

Read more here:

- "Basic Steam Engineering"

- "The Effects of Nucleate Boiling Versus Film Boiling on Heat Transfer in Power Boiler Tubes"

- "An Overview of Surface Roughness Effects on Nucleate Boiling Heat Transfer"

See Also

Magazine Articles

- "Boiler Q & A (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, January-February 2000

- "Introducing Marty Knox - Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, January-February 2000

- "Laying Out Firebox Stays - Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, November-December 2000

- "Making MORE Steam - Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, July-August 2001

- "Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, July-August 1999

- "Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, November-December 1999

- "Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, September-October 1999

- "Making Steam: Some Thoughts on Welding (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, May-June 2002

- "Marshall Black's Boiler Feedwater Treatment Revisited - Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, September-October 2000

- "Response to Marty Knox's Comments on the Filer & Stowell Boiler", Jesse Livingston, Live Steam & Outdoor Railroading, July-August 1999

- "Stayed and Unstayed Boilers - Making Steam (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, July-August 2000

- "Time for a Boiler Wash? (Boilers)", Marty Knox, Live Steam & Outdoor Railroading, March-April 1995

External Links

- Australian Boiler Codes

- "Steel firebox forming", Chaski.org

- Welding Rod Selection for Boilers, Chaski.org

- "Airco welding of locomotive fireboxes, 1919"

- "Soldering flue tubes", Chaski.org

- "Wagon top boilers", Chaski.org

- "Home Built Code Boiler?", Chaski.org

- Boiler plate, Chaski.org

- "4 years of Silver Soldering Hell", Chaski.org

- "Boiler bushings", Chaski.org

- "Boiler Build Thread", Chaski.org

- "Boiler Building + Other Projects by SteamHeaton", Railfan.net

- "Rebuilding the Central of Georgia #408", Chaski.org

- "Mikado Boiler Construction"

- "Boiler Build Issue", Chaski.org

- "SMAW Rods for Boilers"

- "Aligning Front Tubesheet", Chaski.org

- "Boiler stays and heat expansion", Chaski.org

- "Welding Boiler", Chaski.org

- "Understanding types of copper", Chaski.org

- Tube Rollers, Chaski.org

- Tips on tube rolling and hole preparation, Elliott Tool

- "Reaming vs. Drilling Holes In Tube Sheets", Chaski.org

- "At what point is a boiler big enough to be steel instead of copper?", Chaski.org

- "Tube spacing", Chaski.org

- "7" pipe, 9" pipe, 11" pipe", Chaski.org

- "Forming Brass Over 3D-Printed Plastic Formers", Dave Garrett, LSOR Sep/Oct 2023, p.24