Bagley Oil Burner: Difference between revisions

| Line 35: | Line 35: | ||

I found that a common problem with both the Peterson burner and the Bagley burner was trying to control the steam pressure using a standard globe valve. The normal operating pressure range for #486 is 80psi up to 110psi, where the regulators pop. This normal pressure variation was reflected in the burner's steam pressure line. The fluctuation cause uneven burning, and often the flame would extinguish from too little or too much atomizer pressure. | I found that a common problem with both the Peterson burner and the Bagley burner was trying to control the steam pressure using a standard globe valve. The normal operating pressure range for #486 is 80psi up to 110psi, where the regulators pop. This normal pressure variation was reflected in the burner's steam pressure line. The fluctuation cause uneven burning, and often the flame would extinguish from too little or too much atomizer pressure. | ||

Again I returned to the wealth of knowledge on Chaski.org. I learned that other live steamers were using [http://www.clippard.com/ Clippard pressure regulators | Again I returned to the wealth of knowledge on Chaski.org. I learned that other live steamers were using [http://www.clippard.com/ Clippard] pressure regulators in the atomizer line. I ordered a pair of [http://www.clippard.com/part/MAR-1P-2 MAR-1P-2] regulators, one for installation, and one for the [[Toolbox of Requirement]]. The regulators cost $15 each, and I received them within a week. | ||

I tested the newly installed Clippart pressure regulator at [[Houston Area Live Steamers|HALS]] Chugga Chugga Chili Fest that same month (yes, it is quite warm in Houston in February), and was very pleased with the results. It is much easier to keep a good flame, and I spent more time looking at the road ahead and less time with my head down in cab. | I tested the newly installed Clippart pressure regulator at [[Houston Area Live Steamers|HALS]] Chugga Chugga Chili Fest that same month (yes, it is quite warm in Houston in February), and was very pleased with the results. It is much easier to keep a good flame, and I spent more time looking at the road ahead and less time with my head down in cab. | ||

Revision as of 08:39, 1 July 2013

The Bagley Oil Burner

by Daris A Nevil

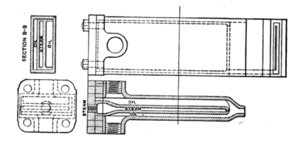

Dick Bagley contributed a great deal to the Live Steam hobby. One of his contributions was the design of a "Sheedy"-style oil burner. He scaled his burner down from the original drawings in the Locomotive Encyclopedia. Dick's oil burner has been used from 1-inch scale locomotives up to 1.5" scale Pacifics. They are easy to install and control.

An article on the Bagley oil burner was published in "Live Steam" magazine, November 1981, page 16.

In addition to the oil burner article, there is another article by Dick Bagley called "Oil Firing a Miniature Locomotive" in the January 1982 issue of "Live Steam".

Availability

Will Campbell of Oakhurst, California has been manufacturing the burners for many years. On 27 June 2013 Will announced on Chaski.org that he is turning over sales of the burners to Tom & Judy Opperman. Judy is Dick Bagley's granddaughter.

You can reach Tom & Judy at 480-947-6586 or Email Judy at mrstraingod@yahoo.com.

The burners sell for $60.00 each.

Installation on #486

The summer months are too hot in Texas to run live steam, so we switch to indoor projects where we can escape the heat (yes I have an air condition in my shop!). In the summer of 2012 I determined to upgrade the oil burner in my Allen Mogul #486. It came with a Chet Peterson style round oil burner. It worked ok, but I did not like the way it was mounted. In addition, it tended to leak fuel due to the fact tat some of the threads were partially stripped.

I had read about the Bagley burner sold by Will Campbell on Chaski.org. So I called Will to find out more information.

He was a wealth of information. He said the Bagley burners are easy to control. They are cast out of Navy Brass, which is very durable and hard. That way the steam does not "cut" the tiny orifices. There is no machining involved, it is ready to use. It requires a #8 screw to a bracket. The steam line is threaded for 3/16" and the oil line is threaded for 5/16" standard Cole's Models taper threads. The brass needle valve I was already using would be fine for oil control. We talked about air flow on the Mogul. Mine had a plat that covered a one-inch tall gap just under the cab floor that leads into the firebox. He said I should remove the plate covering the gap. This will give it enough air. I mentioned that I would often hear oscillations with the firebox door closed. Will said this means the fire is not getting enough air.

Will warned against running the fire too hot. He said this burner can run a blue (hot) flame if you run it with too much steam pressure and too lean on the oil. He said the stack exhaust should have a slight haze; if totally clear it is too hot. It could melt the boiler. He knew someone who melted their aluminum petticoat by running too hot. The firebox should be "incandescent" yellow.

Steam Pressure Regulation

I found that a common problem with both the Peterson burner and the Bagley burner was trying to control the steam pressure using a standard globe valve. The normal operating pressure range for #486 is 80psi up to 110psi, where the regulators pop. This normal pressure variation was reflected in the burner's steam pressure line. The fluctuation cause uneven burning, and often the flame would extinguish from too little or too much atomizer pressure.

Again I returned to the wealth of knowledge on Chaski.org. I learned that other live steamers were using Clippard pressure regulators in the atomizer line. I ordered a pair of MAR-1P-2 regulators, one for installation, and one for the Toolbox of Requirement. The regulators cost $15 each, and I received them within a week.

I tested the newly installed Clippart pressure regulator at HALS Chugga Chugga Chili Fest that same month (yes, it is quite warm in Houston in February), and was very pleased with the results. It is much easier to keep a good flame, and I spent more time looking at the road ahead and less time with my head down in cab.

I highly recommend atomizer pressure regulation for anyone thinking of switching over to oil. If you like do-it-yourself projects, try building this steam regulator.