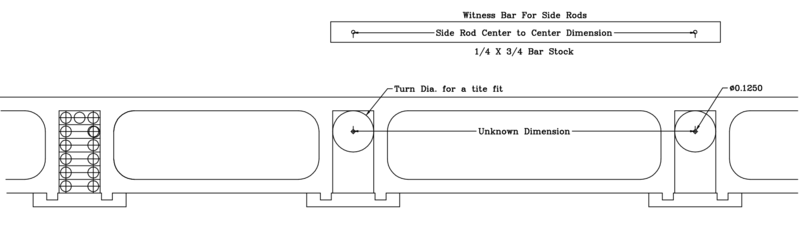

Witness Bar for Side Rods

Will posted the following on Chaski.org:

I recently read a posting about frames. He was concerned with the dimensions that he had gotten after machining them. The main problem was to do with the journals, and how well he had machined them to size.

I read about this fix in The Miniature Locomotive May 1952 issue.

I have done it this way many times myself. Here is a way to do them with a small mill without a DRO.

Everybody agrees that both frames must be done together however you want to hold them together is up to you.

Paint them with layout dye and mark everything to be machined.

You can drill holes and hacksaw them out, then mill the journals with your small milling machine. No DRO used here. See the drawing below.

After you finish machining check all the journals for the dimensions that you wanted. If they are not all the same size for whatever reason, they must be all opened up to the largest journal size that you found. On the journals that you will re-machine I only take off on one side to make it the size that I needed. If you try to machine both sides it will only give a chance to make more mistakes.

If you're thinking now my center-to-center on my journals are not to print, you should not have been so far off as it cannot be saved.

We are now going to fix it so your side rods will work. Take a piece of bar stock large enough to turn a plug that will fit tight in the journal box and long enough so you can cut off two pieces after turning as long as the thickness of each frame. Before you take the piece out of the lathe, center drill it. Then drill a 1/8 inch hole deep enough so when you part off two pieces the length of the frame thickness the hole will go through them. If you are working on a large scale locomotive, you could use a larger drill.

You will use the plugs to make a witness bar for the center-to-center dimension of the side rods. If you are making a locomotive with more drivers, you will make a bar for each length of side rod needed.

As shown in my drawing, place a plug in each journal to make the witness bar. This will give you an acquire dimension to be able to transfer the holes of each side rod needed. Drill through the first plug in the bar; insert a 1/8 inch pin to hold that position. Drill through the next plug for your exact measurement of the side rod.

Because you may have remachined some of the hournals, your center-to-center of the drivers will be off a few thousands. But the side rods will now be the right length for them.

If all your machining was right the first time, and nothging was off, you only need to make the plugs and witness bars to transfer to your side rods. No need to measure that length.

Good Luck.