Titus Gasoline Burner

Gasoline Burner

The North American Live Steamer, Volume 1 Number 4

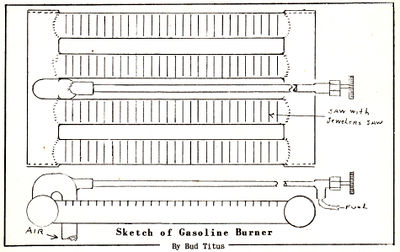

As several fellows have shown an interest in the burner for my engine, I am enclosing a sketch of the one I made up to burn gasoline. No sizes are given, as it would be made to fit inside the fire box.

This one was made of brass tubing, using that which was at hand, silver-soldered together. The header is a piece of 7/8 inch and the rest of 3/4 inch. The generator was taken from a Montgomery Ward gasoline stove, and shortened so it wouldn't extend beyond the cab, but would enter the fire-box and burner, through the firehole. It was connected to the tank in the tender with a piece of flexible oil line from an automobile. The burner slots were cut with a jeweler's saw, or a small 6-inch hack saw may be used. To avoid generator troubles, it is necessary to use white gasoline.

Since there are a few gasoline stations handling white gas, I started experimenting with Propane gas, using the same burner, but without the generator. The elbow on top was cut off, and turned around so as to stick through the fire hole.

Although this burner may not be correct from a mechanical standpoint, it does make steam, and 2 pounds of Propane will run the engine for about an hour.

With the help of Herb McKleroy, who supplied ideas and parts, we dreamed up a way to make the burner work automatically. The Propane is carried in the tender in a small refrigerant cylinder, which holds 2 pounds of gas. An expansion valve is mounted in the tender to control the pressure. To shut the burner down, when the pressure of the steam in the boiler got up to the working pressure, we used a thermostatic expansion valve, as used in commercial refrigeration. As this valve is made to shut off at low pressure, it was necessary to reverse the action, which was accomplished by moving the needle valve to the other side of the seat and putting the actuating plunger where the valve was. As these valves are operated by a bellows connected to a small copper tube, with a bulb on the end and filled with refrigerant, the bulb is cut off and the pipe connected to the steam turret on the boiler, so as the steam pressure rose, it expanded the bellows which pushed the needle valve closed. This shut off the flow of gas through the valve. There is a spring pushing against the valve, with an adjusting screw, by which you can adjust the valve to close at the desired pressure.

The valve in the tender is adjusted to give maximum flame height of the burner, when there is no steam pressure. A 1/8 inch copper tube is connected between the two control valves, through a screw down valve, and just pokes up into one corner of the firebox, and is used as an aid in lighting the burner. It will also serve as a pilot light in the same way as the pilot light in the domestic gas stove.

It is necessary to have a blower on when lighting the burner, and by opening the valve to the pilot tube, it can be lit with a cigarette lighter.

I use two tanks and when one runs empty it only takes a minute to change tanks. The burner control valve is set to keep the steam pressure at 80 pounds, and the pop valves are set to 85 pounds. When running the engine you can stop and let it set for as long as you wish and the pop valves do not keep popping and blow away all your water.

I feel that a more efficient burner could be built, but at present I am engaged in building a new chassis for my 3/4 inch scale Hudson.

- Bud Titus

- 2621 Richmond Ave.

- Mattoon, Illinois