Ronald Allen

"O Gauge Hudson Live Steamer"

by A. Ronald Allen

The Model Craftsman, June 1944

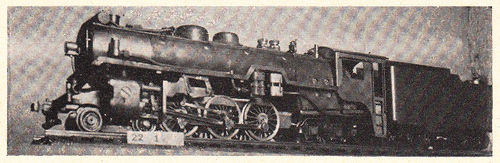

The picture shows the result of my efforts to build the O gauge Hudson type steam locomotive, following the instructions by John Lauder given in The Model Craftsman in 1935 and 1936. I made numerous changes in the plans as published, in order to make the complete locomotive resemble the C.P.R. Hudson or 2800 class. Most noticeable of these changes are the alligator type cross-head, instead of the single bar type, the dummy feedwater heater and the "all-weather" type of cab.

The parts of this locomotive came from many sources. The main frames were cut out by hand from pieces of automobile frame steel and filed from 3/16 inch thick, down to the specified 5/32 inch. Side and connecting rods and trailing truck frames are made of the same material. The flutes in the rods were made by a one-tooth "milling cutter" ground out of the end of a power hacksaw blade. The pistons and piston rods were made in once piece, from the stem of an old monel metal starting air valve, which had seen service in a Diesel engine. All valve gear parts are case-hardened, and are made of the same material as the frames and rods. The cylinders and engine truck frames are brass castings from my own patterns. The driving wheels are Nickelene castings, purchased at a hobbycraft store. The sanddome, smokebox front and tender truck castings came from C.A. Cole, Ventura, Calif. The pilot beam is made from a piece of cast iron, which was cut from an automobile cylinder head.

Two boilers were made for this engine, the first being constructed from the directions given the The Model Craftsman. This boiler had an oxyacetylene-brazed inner firebox and combustion chamber. The balance of it was riveted and caulked with soft solder. This boiler was not a success, not even to the extent of standing the hydraulic tests. I do not blame the published design for this, but believe it was due to poor workmanship and doubtful materials. An attempt was made to salvage the tubes and barrel of the boiler, with the expectation of being able to use them in another boiler. After the dismantling process was over, it was decided that the best course to follow would be to make a fresh start with all new material. A piece of 2 inch copper tube was ordered and when this arrived a new boiler was built, following LBSC's design in The Modelmaker for "Lucy Anna's" boiler. Lucy being a 4-8-4, the boiler had to be shortened to suit my 4.6.4, which by this time had come to be known as the "Worry Wart." The boiler was all brazed, with easy running brazing strip for the firebox and combustion chamber, and silver solder for the remainder. Heat was supplied by two gasoline torches, the job being packed in coke. When testing the boiler withstood 120 pounds water pressure O.K.

The tender was built from 1/32 inch sheet brass, as was the cab. The hand waterpump is under the cab, rather than in the tender tank, this doing away with the necessity of a high pressure connection between engine and tender.

The superheater is installed between the boiler and throttle which lessened its tendency to burn out. A new front-end throttle was designed and built to allow this to be done. Other fittings include blower valve fitted to hollow stay, and the usual water gauge. A displacement lubricator is fitted under the cylinders. Dummy air and feedwater pumps are located on the left hand side, under the running board.