Rivets

Jump to navigation

Jump to search

Suggestions

From livediesel@yahoogroups.com, May 2013:

- JP wrote:

- MCC uses 3/32" rivets typically 3/8" or 5/16" long. I have found that http://www.aircraft-tool.com/ has the best prices for rivets and rivet related items.

- Bill Koster wrote:

- I have used #2 drive screws to simulate rivets. Though oversize, they give a good appearance. Their head is about the same size as a 2-56 round head screw, but without the slot.

- Jimi wrote:

- Are you looking for scale rivets ? For small rivets, try using the heads of common pins. (Raid your wife's sewing box.) Of course they can't be used to hold two pieces of steel together, but they look nice.

- Weld the steel at the joints to hold the pieces together. Then drill a very small hole to insert a pin and cut the excess off the back. If you have a good welder (TIG) tack weld the pin from the backside.

- For a rivet a little bigger, look in the nail aisle at Home Depot and buy some brads with rounded heads. Drill, insert, cut and tack weld from the back. It worked great on the cow catcher I built.

- Laurence Johnson wrote:

- For the stake pockets on a flat car I used #6 finishing nails; small holes and cut in back leaving 1/8 inch exposed, two blows with hammer and nail set to flatten the head and then touched the back w/wire welder. Looks and holds well.

- Bruce Mowbray wrote:

- I used 3/32 rivets with a .130" diameter head brass rivets for my tender. This scales out to a 3/4" diameter head. Typical for tank work on full sized locomotives. I didn't use Clecos as I don't feel that they hold things tight enough. Instead, I used #3-48 allen head cap screws and nuts. They fit the holes tightly and didn't take up as much room in the work zone as the Clecos. A box of 500 screws was $8.99 at MSC. I had the nuts laying around.

Video

Four Methods of Flush Riveting, Walt Disney Studios

Installing Aircraft Solid Rivets

Blind Holes

Tight Rivets in Blind Holes, from "Popular Mechanics Shop Notes for 1921":

- The sketch shows how a rivet can be fastened securely in a blind hole. Before the rivet is inserted, a hole is bored in its end, and a steel ball dropped into the blind hole. When the rivet head is hammered, the ball is forced into the hole in the rivet, expanding the latter and seating it firmly.

Rivet tape

Doug Blodgett shared the following:

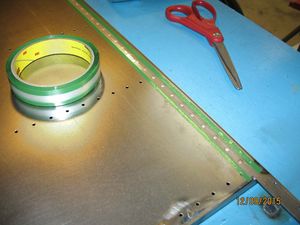

- My rivet tape arrived today. With about 1100 rivets to install on this PSC boxcar, I decided to try some rivet tape to speed things up. It "works a treat" as my British friends would say. Here are a couple of photos showing how it works. Basically it lets you pre-install the rivets, cover them with a special tape, and then rivet them at one sitting without having to stop each time to install another one.

Here you can see that the rivet set goes right over the tape when bucking. Tape is peeled off each row as it is finished. Using the tape makes the process go incredibly fast with a lot less effort. I got the tape from Aircraft Tool Supply Company.

External Links

- "A Riveting Article (or how to set rivets without going crazy)", DiscoverLiveSteam.com

- "Riveting with SS rivets", Chaski.org

- Solid Rivet Size Chart

- "Rivets", Chaski.org

- Riveter's Tape 3/4 inch wide, Aircraft Tool Supply Company

- "Riveting", Chaski.org

- "Riveting the tender", Chaski.org

- "Hopper Car Build", DiscoverLiveSteam.com

- "The Start of Riveting a Tender Tank in 3/4 inch Scale", Chaski.org

- "Sprayberry Hopper Assembly", Chaski.org

- "A Riveting Article: How to Set Rivets Without Going Crazy", Chaski.org