Rail inspection

Rail inspection is the practice of examining rail tracks for flaws that could lead to catastrophic failures.

There are many effects that influence rail defects and rail failure.

Defects due to contact stresses or rolling contact fatigue (RCF):

- tongue lipping

- head checking (gauge corner cracking)

- squats - which start as small surface-breaking cracks

Parts of a rail where defects can be found:

- head

- web

- foot

- switchblades

- welds

- bolt holes

A majority of the flaws found in rails are located in the head, however, flaws are also found in the web and foot. This means that the entire rail needs to be inspected.

See also:

Head grading

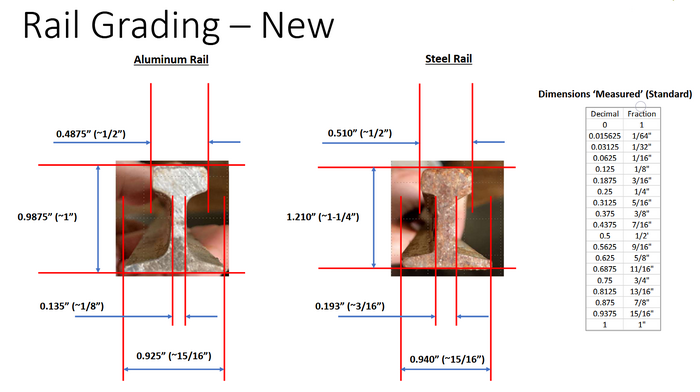

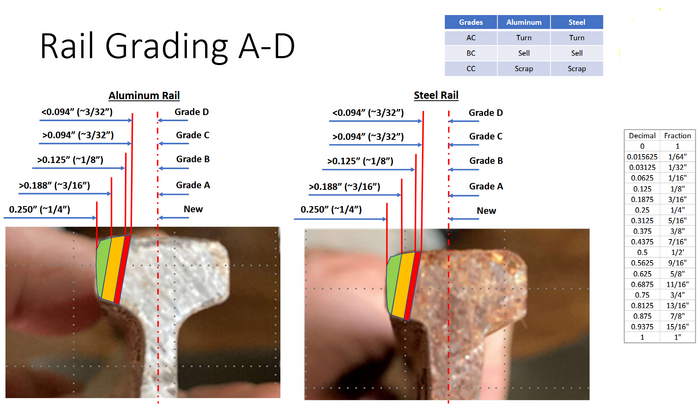

Crispin Richards proposed a method for 7.x gauge rail "grading" or inspection. This is a starting point for consideration. A railroad adopting this method of Rail inspection may want to adjust the wear levels to suite their needs.

In practice, short sections of rail samples modified (ground down) to represent the transitions from one grade to the next are best used so anyone can perform the inspection.