Popular Science

Feb 1941

Ed: This article contains multiple errors. It appears here exactly as it appeared in the original magazine article.

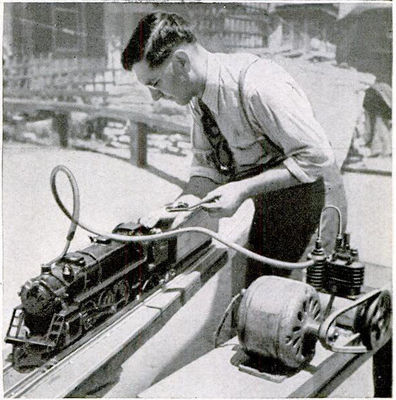

Today more than 2,000 men and boys in the United States are busily constructing miniature steam engines of all kinds, ranging from accurate scale-model locomotives to engines for miniature industrial plants. One of these locomotives recently whisked eight husky men around a circular track at a 20-mile speed. Another model completed not long ago was a working reproduction of the first Corliss team-plant display at the Philadelphia Centennial in 1876.

These model builders are members of the National Association of Live Steamers. They are rapidly reviving the old hobby of constructing working models which depend on steam for their motive power. The Association has local units throughout the country, and live steamers gather at regular meetings to demonstrate new models and check up on new tricks of the trade.

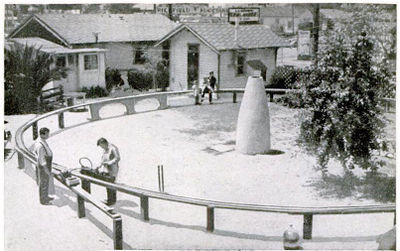

One of the most active groups of the association is the New England Live Steamers Club. It has 56 members who boast a combined rolling stock of 36 engines, 14 flat cars, five hopper cars, a sand car, and a dynamometer car that is used for testing the power of their locomotives.

To become a member of the National Association a model builder has only to begin construction of a working steam model and notify the organization in care of Lester Friend, Danvers, Mass. To remain in good standing, however, members are expected to make their models perform when they are completed.

Beginners interested in locomotive construction are advised to use a scale of three quarters of an inch to the foot, and start with the plans of a simple model such as a 4-4-2, which has four wheels under the pilot, four drivers, and two wheels under the cab, or an 0-6-0, with six drivers. The most popular types are the Pacific, Atlantic, Hudson, and Mountain locomotives. Costs run from $20 for a simple Tom Thumb, popular with boys, to several hundreed dollars for a large-size freighter.

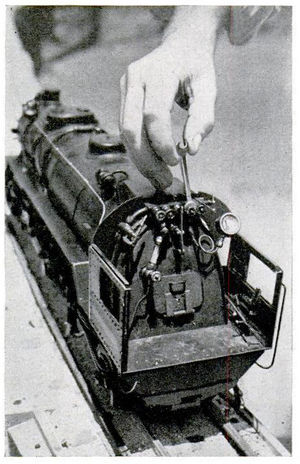

Some model steam plants can be turned out in a few weeks, but many dyed-in-the-wool live steamers think nothing of taking several years to complete a precise job. Dan Kugler, a Los Angeles jeweler, recently finished, after five years of work, a complete train 90 inches long. Working with an inlarging glass, he bored 18,000 tiny holes and pounded in 18,000 rivets, mushrooming the head of each with a doll-size hammer.

Noah Blough, an Illinois gadgeteer, has different ideas. He goes in for mass production. Working with what he termed "raw materials and junk," Blough turned out his first job, a small stationary engine, a few years ago. Since then he has polished off working models of a locomotive, a steam traction engine, a two-yclinder marine engine, six more stationary engines, and a steam-powered speed boat.

George Hartness, of New York City, admired the old Case tractor of a generation ago. Unable to obtain plans, he secured pictures from an old catalog and went to work. After 1,500 work hours he had assembled 2,135 pieces into the completed machine. it cost him $100 in tools and materials, but a professional model maker asked $3,000 to produce a duplicate.

The Corliss steam plant was the work of L.E. Hiney, of Sawtelle, Calif. Enthused by his mother's recollections of the original, he built his model in a five-foot building which he keeps on a table in his home. It has everything from boiler and engines down to a workbench and tools. One of the latter is a vise that Hiney believes is the smallest in the world. It is seven eights of an inch long and weighs one ounce.

Running live-steam model locomotives is just like real railroading, one enthusiast says. "You blow your whistle, cuss the dispatcher, and dig cinders out of yours eyes."

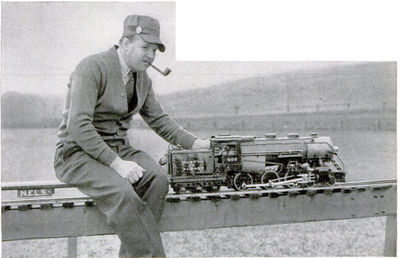

Lester Friend, organizer of the National Association, ready for a ride around the 620-foot loop maintained by the New England club at Danvers, Mass. He is sitting on a flat car.