Petticoat: Difference between revisions

(Created page with "Category:Definitions Category:Steam Locomotive Parts by "North Eastern" <i>The Live Steamer</i>, September-October 1950 The question has been asked in an issue ...") |

No edit summary |

||

| Line 7: | Line 7: | ||

The question has been asked in an issue of [[The Live Steamer]], "What purpose does the flared out bottom extension of a locomotive stack server?" | The question has been asked in an issue of [[The Live Steamer]], "What purpose does the flared out bottom extension of a locomotive stack server?" | ||

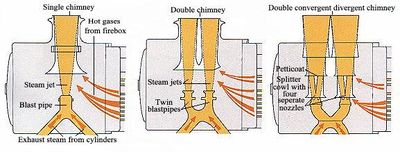

[[File:BlastPipesAndPetticoatSmokebox.jpg|thumb|right|400px|Diagram showing blast pipes and petticoats in firebox. From [http://www.greatwestern.org.uk/basic9.htm "The Great Western Archive"]]] | |||

To induce the draught necessary in a locomotive firebox, exhaust steam is directed up the [[Smokestack|smokestack]] creating a vacuum in the smokebox and drawing air through the grate bars and fire. All gases, and we can regard exhaust steam as a gas, emerge from an orifice in the form of a cone whose total angle is approximately 10 degrees. For efficient draughting, steam from a locomotive exhaust pipe must completely fill the stack. In earlier days when stacks were tall and shapely (there were some monstrosities I will admit, but internally at least they were all similar) the 10 degree cone of exhaust steam had no difficulty filling them. Boilers, however, got fatter and stacks shorter and shorter until, unless something was done about it, the exhaust steam would pass right out to the atmosphere without going anywhere near the sides of the stack. So designers began to extend the smokestack inside the smokebox instead of outside, to provide sufficient length for the 10 degree cone to fill. Also since the smokebox gases had to be ejected by the exhaust steam, the bottom of the extension was usually flared out to a varying degree to allow the gases easy entry to the stack. | To induce the draught necessary in a locomotive firebox, exhaust steam is directed up the [[Smokestack|smokestack]] creating a vacuum in the smokebox and drawing air through the grate bars and fire. All gases, and we can regard exhaust steam as a gas, emerge from an orifice in the form of a cone whose total angle is approximately 10 degrees. For efficient draughting, steam from a locomotive exhaust pipe must completely fill the stack. In earlier days when stacks were tall and shapely (there were some monstrosities I will admit, but internally at least they were all similar) the 10 degree cone of exhaust steam had no difficulty filling them. Boilers, however, got fatter and stacks shorter and shorter until, unless something was done about it, the exhaust steam would pass right out to the atmosphere without going anywhere near the sides of the stack. So designers began to extend the smokestack inside the smokebox instead of outside, to provide sufficient length for the 10 degree cone to fill. Also since the smokebox gases had to be ejected by the exhaust steam, the bottom of the extension was usually flared out to a varying degree to allow the gases easy entry to the stack. | ||

| Line 15: | Line 17: | ||

In my own experience, the amount of flare doesn't matter much. Some of the best steaming locos I ever knew had petticoats with no flare at all to speak of and a diameter at the bottom of only 11 inches (I got stuck in one once). They projected into the smokebox as part of the stack casting. | In my own experience, the amount of flare doesn't matter much. Some of the best steaming locos I ever knew had petticoats with no flare at all to speak of and a diameter at the bottom of only 11 inches (I got stuck in one once). They projected into the smokebox as part of the stack casting. | ||

== External Links == | |||

* [http://www.greatwestern.org.uk/basic9.htm "Blast Pipes"]] | |||

Revision as of 17:22, 20 July 2014

by "North Eastern"

The Live Steamer, September-October 1950

The question has been asked in an issue of The Live Steamer, "What purpose does the flared out bottom extension of a locomotive stack server?"

To induce the draught necessary in a locomotive firebox, exhaust steam is directed up the smokestack creating a vacuum in the smokebox and drawing air through the grate bars and fire. All gases, and we can regard exhaust steam as a gas, emerge from an orifice in the form of a cone whose total angle is approximately 10 degrees. For efficient draughting, steam from a locomotive exhaust pipe must completely fill the stack. In earlier days when stacks were tall and shapely (there were some monstrosities I will admit, but internally at least they were all similar) the 10 degree cone of exhaust steam had no difficulty filling them. Boilers, however, got fatter and stacks shorter and shorter until, unless something was done about it, the exhaust steam would pass right out to the atmosphere without going anywhere near the sides of the stack. So designers began to extend the smokestack inside the smokebox instead of outside, to provide sufficient length for the 10 degree cone to fill. Also since the smokebox gases had to be ejected by the exhaust steam, the bottom of the extension was usually flared out to a varying degree to allow the gases easy entry to the stack.

The "smokebox extension" (its actualy name on many roads), or "petticoat pipe" is actually a portion of the smokestack, compensating for the almost (in some cases) non-existent stack to be seen outside. The amount of flare at the base seems to be one of those questions never satisfactorily answered. Much experimenting was done all over the world, but every railroad apparently still has its own ideas.

Petticoat pipes were often made up in series, one above the other making as many as four or five separate flares. That type of petticoat is still common on certain oil burning locomotives.

In my own experience, the amount of flare doesn't matter much. Some of the best steaming locos I ever knew had petticoats with no flare at all to speak of and a diameter at the bottom of only 11 inches (I got stuck in one once). They projected into the smokebox as part of the stack casting.