Marty Burners: Difference between revisions

| Line 28: | Line 28: | ||

[[File:Dave Augusts version of Marty burners.png|thumb|center|300px]] | [[File:Dave Augusts version of Marty burners.png|thumb|center|300px]] | ||

=== Parts for Two Marty Burners === | |||

That 3 inch long 1/8 brass pipe nipple cost $1.75. This will make two Burner Bodies. | |||

Around here the brass pipe caps are made from 9/16 hex brass. That makes it easy to index the piece when it come time to slot it. They each cost $1.50. | |||

That's a small chunk of brass from my scrap box to make the orifice plugs. The inside diameter of the brass pipe is nominally 9/32. That's not a common size for brass rod so I usually turn a piece scrap. I suggest that you anneal the brass before you turn it to size. I've broken the #71 drill going through hard brass. If you can get some 9/32 brass, it's one less thing to do. It will make a tight press since the end of the nipple gets compressed when it's threaded. We could be generous and say it cost 25 cents. | |||

Let's see, that's a total of 5 bucks in materials cost for 2 burners. They are not real budget busters. | |||

[[File:MartyBurnerParts.jpg|thumb|center|300px]] | |||

=== Turn the Cap === | |||

First I turn the cap to about 0.450 for a length of 0.300. This diameter isn't a critical dimension. It just needs to be thin enough that the slot saw will cut all the way through it. If I can find a slightly bigger diameter saw I could eliminate this step. | |||

[[File:MartyBurnerTurnTheCap.jpg|thumb|center|300px]] | |||

=== Slot the Top === | |||

I use my milling maching to slot the top. If you don't have a mill, I'm sure you could build a simple fixture that would allow you to use the cross slide on your lathe to do this. Notice that I have a vice stop clamped in place. It both "backs up" the piece and makes it a simple matter to index the piece from the sides. Also notice how close the slot saw shaft is to the cap. The only critical thing here is to keep the distance between the tops of the slots bigger than 0.250. This is just under the 0.281 ID of the tube. DO NOT slice the top all the way through the center. The top of the cap deflects the gas mixture down and around the tube top. | |||

[[File:MartyBurnerSlotTheTop.jpg|thumb|center|300px]] | |||

=== Drill the Body === | |||

The first step in making the body is to drill the air mixture hole through the tube. The distance from the base of the Body isn't critical, I arrived at the 0.550 as a place where the bottom of the hole just touches the end of the 1/8 pipe threads. It could be closer to the end, I don't think I'd get it closer to the cap. | |||

[[File:MartyBurnerDrillTheBody.jpg|thumb|center|300px]] | |||

== References == | == References == | ||

Revision as of 16:11, 21 May 2013

"Marty Burners" refers to a propane-fired burner for live steam locomotives. They are named after the developer, Marty Siegel.

Construction

by Dave August

From Golden Gate Live Steamers and Archive.org

Many people have ask me how come my locomotive steams so well. My answer is that it has 'Marty Burners' in it.

Marty Siegel was a very knowledgeable and friendly club member who was always ready to offer his advice on a good problem. Back in 1998 I was complaining to Marty that my 'Tube and Slot' propane burner just wasn't giving me enough BTUs. He suggested that I try a set of these burners.

As Marty told me, he was helping another club member, Jim Dameron, get the firing right on Jim's Pacific. Marty was so impressed with the simplicity and efficiency of the commercial burners in Jims engine that he took the time to make a set of drawings for them.

Many club members have built variations of these burners and all of us have had good success. After a while we just started calling them 'Marty Burners'.

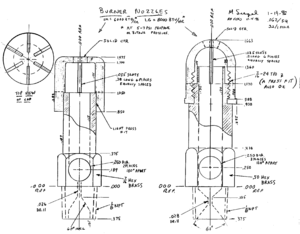

This is a scan of Marty's original drawing and should print out at 8.5 x 11.

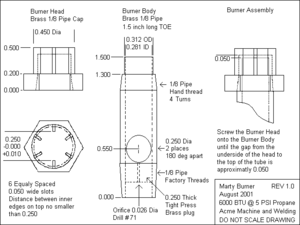

When I decided to build a set of these burners I didn't have the hex brass. Besides that, I couldn't bring myself to throw that much brass in the trash. I looked at the design and figured it was just a piece of brass pipe with a plug in it, so that's how I built mine. When I first looked at Marty's drawing the only thing that bothered me was the slot saw for the burner head. Dremel makes one that is 0.050, and it seems to work just fine. These slots are a bit shorter so being wider helps keep the area about the same. If they are properly built they will run at well over 15 PSI before the flame jumps from the head. That's quite a lot more than 6000 BTU.

This is a drawing for my version of the burners.

Parts for Two Marty Burners

That 3 inch long 1/8 brass pipe nipple cost $1.75. This will make two Burner Bodies.

Around here the brass pipe caps are made from 9/16 hex brass. That makes it easy to index the piece when it come time to slot it. They each cost $1.50.

That's a small chunk of brass from my scrap box to make the orifice plugs. The inside diameter of the brass pipe is nominally 9/32. That's not a common size for brass rod so I usually turn a piece scrap. I suggest that you anneal the brass before you turn it to size. I've broken the #71 drill going through hard brass. If you can get some 9/32 brass, it's one less thing to do. It will make a tight press since the end of the nipple gets compressed when it's threaded. We could be generous and say it cost 25 cents.

Let's see, that's a total of 5 bucks in materials cost for 2 burners. They are not real budget busters.

Turn the Cap

First I turn the cap to about 0.450 for a length of 0.300. This diameter isn't a critical dimension. It just needs to be thin enough that the slot saw will cut all the way through it. If I can find a slightly bigger diameter saw I could eliminate this step.

Slot the Top

I use my milling maching to slot the top. If you don't have a mill, I'm sure you could build a simple fixture that would allow you to use the cross slide on your lathe to do this. Notice that I have a vice stop clamped in place. It both "backs up" the piece and makes it a simple matter to index the piece from the sides. Also notice how close the slot saw shaft is to the cap. The only critical thing here is to keep the distance between the tops of the slots bigger than 0.250. This is just under the 0.281 ID of the tube. DO NOT slice the top all the way through the center. The top of the cap deflects the gas mixture down and around the tube top.

Drill the Body

The first step in making the body is to drill the air mixture hole through the tube. The distance from the base of the Body isn't critical, I arrived at the 0.550 as a place where the bottom of the hole just touches the end of the 1/8 pipe threads. It could be closer to the end, I don't think I'd get it closer to the cap.

References

- "Marty Burners" by Dave August, Archive.org

- "Building Marty Burners" by Dave August, DiscoverLiveSteam.com

- "Propane Burners", Live Steam & Outdoor Railroading

- "Propane burners", Live Steam & Outdoor Railroading

- "Propane Burners for 3/4" scale Live Steam", Chaski.org

- "Propane Burner design", The Home Shop Machinist

- "Marty burners", Chaski.org

- "Propane baffle plate", Chaski.org