How to Form Brass Domes

The Model Craftsman, June 1944

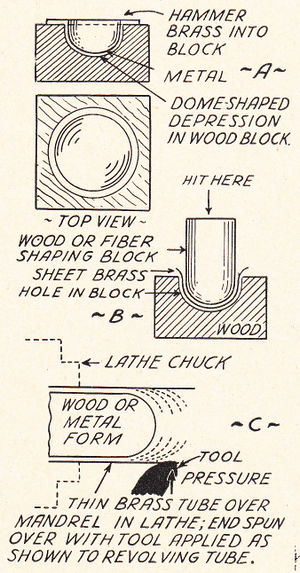

The model railroad builder often finds that he will have to make his own domes for the top of a locomotive boiler. Here are three methods of forming them from thin sheet brass or copper. Sheet zinc can also be used, as well as tin or thin iron if no brass is available. Method "A" involves the use of a die or block, hollowed out by drilling and gouging with a curved wood chisel to the shape of the dome. The thin piece of brass is slowly hammered down into the depression in the block, using preferably a rawhide or fiber hammer. By gently striking the metal lightly all around, in oft repeated circular paths, the dome can readily be shaped.

Method "B" calls for the use of a punch and die, both of which may be made of wood (hard wood is best). The diameter of the punch is made smaller than the hole in the die, to permit the sheet metal to come in between them as the dome is formed. The work should be done gradually ... don't rush it. Also proceed to anneal the brass (or copper) as suggested by Mr. Adams in the February issue, in his article on the construction of the N.Y.C. "Mohawk" locomotive. The brass or copper may be annealed by heating the metal to a good red heat, and then quenching it in water. In this way and by repeatedly heating and quenching the metal at various stages of the forming process, the metal can be worked into the desired dome shape. Afterward the metal can be cleaned with emery paper and the flange soldered to the boiler.

The third method, shown at "C", is that of spinning the brass or copper to the dome shape. A piece of brass tubing (thin stock) is fitted over a hard wood pattern of the desired shape and fastened in a lathe chuck as shown. As the piece of tubing spins, pressure is exerted against it by a round-nosed tool as the illustration shows, gradually forming the end of the tube into the shape of a bell. The metal may be annealed as explained above, which will make the process still easier. A hand tool may be used for performing this operation.

If the top of the dome is not entirely closed, it may be filled with a piece of brass soldered into place, and the whole finished off with a piece of emery paper.