Finishing Spring Ends

by George Hill

Toronto, Ontario

The North American Live Steamer, Volume 1 Number 10, October 1956

A method of finishing the ends of small spiral compression springs for locos, tools, etc., that I use may be of interest to fellow live steamers.

The way I proceed is to wind up a long length of music wire on a drill rod mandril held in the vise in the usual way atwixt a pair of wooden clams. Not bothering about spacing of coils, as long as they are not too far apart. I then catch the spring end and mandril in vise, and haul on the end that is free until it sets at the required pitch. Brutal, when compared with the more refined lathe winding setup, yet just as effective.

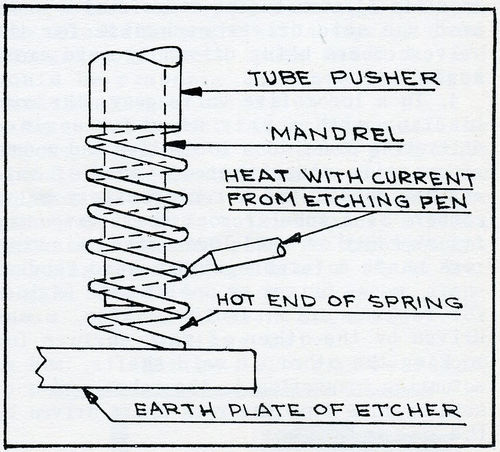

Now comes the brainy bit. First cut off the springs to a length of 3 to 4 coils more than the free length required. The books say "grind the ends square" - I wonder if they ever tried it? What works for me is the resistance heating method, source of current being the electric etcher - of all things! It's a Jim Dandy for heating up the last coil or so of a spring, which can then be closed up to it's neighbor and form a nice square end good and solid. This is done with the spring again on the mandril, using a piece of tube as a pusher if the spring is at all on the short side. Try your first one with the juice turned to low, as the spring end heats up but fast. Maybe a car battery could sub for the etcher, or even a large model railroad transformer in a pinch. The ends lastly can be ground flat; even so I do not find this refinement really needed any more. The sketch will give some idea of what goes on.