Donald Yungling: Difference between revisions

No edit summary |

|||

| Line 49: | Line 49: | ||

File:Marty's spring rigging 520.JPG | File:Marty's spring rigging 520.JPG | ||

File:Marty's spring rigging 882.jpg | File:Marty's spring rigging 882.jpg | ||

File:Marty's spring rigging 739.jpg | |||

File:Marty's spring rigging 523.JPG | |||

File:Marty's Lead Truck 051.JPG | |||

File:Marty's Lead Truck 050.JPG | |||

File:Marty's Lead Truck 049.JPG | |||

File:Marty's Lead Truck 048.JPG | |||

File:Marty's Lead Truck 047.JPG | |||

File:Marty's Lead Truck 046.JPG | |||

File:Marty's Lead Truck 045.JPG | |||

File:Marty's Lead Truck 042.JPG | |||

</gallery> | </gallery> | ||

Revision as of 22:08, 31 March 2020

Fitchburg Northern

Donald Yungling shared his experience building a Fitchburg Northern on the associated group.

January 2020

Hello, my name is Donald and I am building a Fitchburg Northern. It started out with my helping my friend Marty build the FN. I would machine the parts he was not comfortable tackling himself or walk him through the process on a particular part, or parts. Unfortunately Marty's health has failed and he is no longer capable of performing machine work. He has given the FN project to me and I am now in the process of continuing with the build.

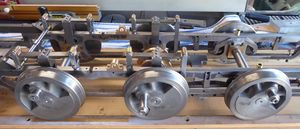

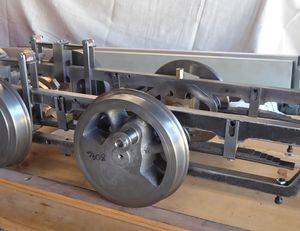

The two attached photographs illustrates progress as of about 2 months ago. Since that time Marty had made the driver leaf springs, driver spring seats and some brake parts. Currently those are in a box awaiting my attention and will be presented to you guys when their turn comes up.

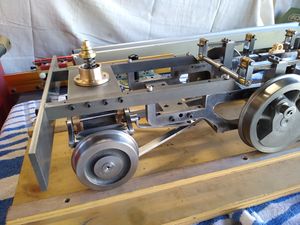

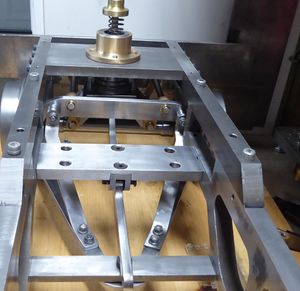

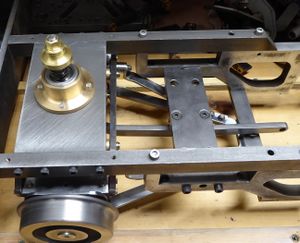

At this time I am building the lead truck. The wheels, center bolster casting, pedestals and swing links have been machined.

I may also add additional videos to my YouTube page of some of the machine work.

Here is Marty operating his beautiful Allen Models on the SVLSRM railroad.

<videoflash>oJn-bPm8OBk</videoflash>

My YouTube channel with some FN machine work

I posted some photographs of some of the various steps in the driver and crankpin build of Marty's FN that I am now building. The photo's are in the Album Marty's Fitchburg on this site. The photo with the quartering fixture is staged. The actual assembly is on a press. First step is to press one driver on about half way. Then an alignment bushing centers the driver to the fixture and the pre-drilled hole aligns the crankpin. Then the axle boxes and eccentrics are added as needed. Tho other driver is aligned on the top plate again using a bushing for the axle center and the crank pin fits in the hole in the upper plate. Once the second driver is on about 1/2 way the alignment pins are removed and the drivers are pressed home. No keys or keyways are needed.to quarter the drivers.

The press fit is more than adequate to hold the drivers in position and to keep the drivers from spinning on the axles. We have used this method on numerous locomotives including my GS-1, and my dad's cab-forward. It has proven to be a very accurate method to quarter drivers.

I made the crank pins 9/16 inch diameter and they, as well as the retaining nuts and washers, are made from 303 stainless.

Meanwhile lead truck progress is being made. The axle, axle boxes and wheels were finished up this afternoon and the lead truck wheels were pressed on the axles.