Cliff Blackstaffe: Difference between revisions

No edit summary |

|||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:People]] | [[Category:People]] | ||

== Gallery == | |||

<gallery widths="300px" heights="300px> | |||

File:CliffBlackstaffe HobbyShow VictoriaBC April1950.jpg|Scene at the Hobby Show of the Victoria, B.C. group in April 1950, shows [[Cliff Blackstaffe]] hauling a load of kids on the Exhibition Track with his "O" Gauge C&O live steam Pacific loco. This little steam loco has actually hauled the amazing load of over 300 pounds (two hefty adults). [[Charles A. Purinton|Carl Purinton]], our Danvers Brotherhood Secretary can verify its ability at adult passenger work since he got a ride behind this engine while on a trip up that way in the summer of 1950. For this type of stunt the "O" gauge loco is coupled to the larger gauge passenger car and does its stuff. The engine was originally coal-fired, but was changed over to an gasoline vaporized burner for convenience in firing up and handling during these passenger hauling chores. "[[The Live Steamer]]", Sep-Oct 1950 | |||

File:CliffBlackstaffe American.jpg|"End of a long day". This is a 44 year old 4-4-0 built by [[Cliff Blackstaffe]]. It is on a private track on Vancouver Island. Photographer: Josh Blackstaffe, grandson of Cliff. | |||

File:CliffBlackstaffe GGLS 1956.jpg|Cliff Blackstaffe taking a turn on the [[Golden Gate Live Steamers|GGLS]] track behind his 0-4-0. From "The North American Live Steamers", January 1956. | |||

File:CharlesCole CliffBlackstaffe LALS BLS Meet 1975.jpg|Coles Power Models display at Los Angeles Live Steamers during the 1975 BLS meet. Charles Cole, son of founder Charles A. Cole, chats with Cliff Blackstaffe. | |||

</gallery> | |||

== Argue Anyone?? == | |||

<i>[[The North American Live Steamer]]</i>, Volume 1 Number 5, 1956 | |||

[[Cliff Blackstaffe]] | |||

Well, [[The North American Live Steamer]] No. 4 has arrived, running a bit late, but it's understandable from the editor's note on page two. It's too bad so many fellows are such skeptics. They say, "wait and see" (if it lasts) which is the very thing that kills it. | |||

Your idea of stretching it out to longer intervals will certainly help your situation, but will have a detrimental effect in getting new subscribers. I'm not kicking though, as I know what you're up against. | |||

To start a little argument (in all respect to [[Harry Coventry|Mr. Coventry]]) on page 11 of No. 4 he considers tubes and heating surfaces. He says it is a mistake to crowd in too many at the expense of the flue area. | |||

[[Harry Coventry|Mr. Coventry]] is one of the few who recognize flue area at all, but he starts from the wrong end. The correct way, which is full size method, is to get the correct length to tube diameter in order that all the heat may be extracted from the flue gasses. The longer the tube, the larger it can be. It works on a ratio of length to cross sectional area. In model practice in 3/4 inch scale a 3/8 inch O.D. tube will suffice for all but the largest engines. The shortest 3/8 inch tube desirable is 6 inch which if the diameter were increased to 3/4 inch i.e., 4 times the cross sectional or flue gas area the shortest desirable tube would then be 4x6=24 inches. An engine with 3/8 inch tubes 8 inches long is a good steamer, not wasting much heat up the stack when driven hard and tubes of 3/8 inch up to 11 inches long are practical, but the extra 3 inches at the smoke box end makes hardly any steam as the heat has already been extracted in the first 8 inches of the tube. | |||

Now we come to long boilers. When the tubes are long it is better to add a combustion chamber to the firebox rather than add useless length to the tubes for, as Mr. Coventry says, a square inch of surface in a firebox is equal to 5 square inches in tubes. | |||

Now to flue area. If you put in as many tubes as you can get, you'll have enough flue area. I'll not start an argument on superheaters. Suffice to say that none of the best steaming engines in the club here have superheaters. They have as many tubes as possible to get lots of gas area. The draft can really pull on the grate so we get a hot fire. | |||

I have a little switcher with 4 inches diameter boiler which is an exceptionally lively steamer, and which for a long time was run with one row of tubes plugged to stop her steaming so violently when driven by visitors. Also, an engine won't steam if she has too large a grate area. | |||

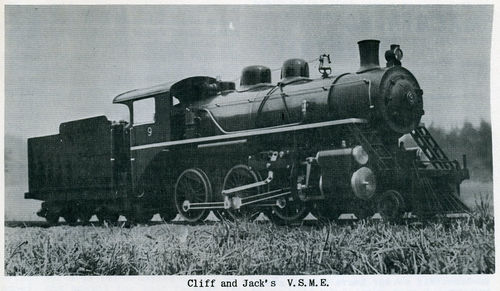

Enclosed is the first photo of our V.S.M.E. standard 4-6-0 3/4 inch scale engines. It was built as a joint effort by Mr. Jack Shaw and myself to my design with castings from my patterns. It is not super detailed, as Mr. Shaw, being a marine engineer, had very little time. It has taken about six years as it is, but really is a very easy engine to build. It has individual coil springs to the driving axle boxes which, though inferior to equalizers, it made the job a lot simpler. The cylinders are separate and bolted to the frames as in English loco practice. | |||

The dimensions are as follows: | |||

* Weight, about 70 pounds | |||

* Cylinders, 1-1/4 by 1-3/4 inches | |||

* Slide valve, travel 3/8 inch, ports 1/8 by 1 inch | |||

* Exhaust 1/4 by 1 inch | |||

* Driving wheels 4-1/4 inch | |||

* Bogie wheels 1-3/4 inch | |||

* Tender wheels 2 inch diameter | |||

* Valve gear, [[Walschaert valve gear|Walschaert]] with box links | |||

the valve gear, connecting and coupling rods, crossheads cylinder cover jackets and running boards are made of dural. Rods are bronze bushed. | |||

Boiler is 4-1/2 inch diameter at the smokebox end tapering to 5 inch at the throat plate, tapering down again to the backhead. Tubes 3/8 inch by 8 inch long, 28 in number. Combustion chamber 2-1/2 inch long, grate area is 2-1/4 inch wide by 6 inch long. Blower jet No. 75 drill. Exhaust nozzle 3/16 inch. Fittings, steam and water gauges, blower and injector valves. Feed is by one [[LBSC|L.B.S.C.]] type injector only. No hand or axle pumps. Throttle is a poppet valve with a metering pilot which gives very smooth starts. It is located in the smoke box. Tender has a metal clad wooden body enclosing a two quart copper tank. The front truck carries no weight, as the tender is carried at the front end through the coupling by the engine drag beam for extra adhesion weight. Minimum curve radius is 10 feet. Cost $60.00. | |||

: [[Cliff Blackstaffe]] | |||

: 1076 Colville Road | |||

: Victoria, B.C., Canada | |||

[[File:CliffBlackstaffe JackShaw VSME.jpg|thumb|center|500px]] | |||

== Bibliography == | == Bibliography == | ||

| Line 5: | Line 57: | ||

* [[Tender Hand Pump for 3/4" Scale Locomotives]] | * [[Tender Hand Pump for 3/4" Scale Locomotives]] | ||

* [[Beginner's Locomotive Safety Valve]] | * [[Beginner's Locomotive Safety Valve]] | ||

== References == | |||

* [http://www.discoverlivesteam.com/magazine/33/33.html "Designers, Publishers & Builders form a Successful and Historic Partnership", <i>DiscoverLiveSteam.com</i>] | |||

* [http://www.smokstak.com/forum/showthread.php?t=68302 "Who's Got a Steam Boat", <i>SmokeStak.com</i>] | |||

* [http://www.farmcollector.com/steam-traction/latest-engine-group-to-form-is-western-steam-fiends-association.aspx#axzz36BqAzgYR "Western Steam Friends Association", <i>Farm Collector</i>] | |||

Latest revision as of 11:19, 13 December 2021

Gallery

Scene at the Hobby Show of the Victoria, B.C. group in April 1950, shows Cliff Blackstaffe hauling a load of kids on the Exhibition Track with his "O" Gauge C&O live steam Pacific loco. This little steam loco has actually hauled the amazing load of over 300 pounds (two hefty adults). Carl Purinton, our Danvers Brotherhood Secretary can verify its ability at adult passenger work since he got a ride behind this engine while on a trip up that way in the summer of 1950. For this type of stunt the "O" gauge loco is coupled to the larger gauge passenger car and does its stuff. The engine was originally coal-fired, but was changed over to an gasoline vaporized burner for convenience in firing up and handling during these passenger hauling chores. "The Live Steamer", Sep-Oct 1950

"End of a long day". This is a 44 year old 4-4-0 built by Cliff Blackstaffe. It is on a private track on Vancouver Island. Photographer: Josh Blackstaffe, grandson of Cliff.

Cliff Blackstaffe taking a turn on the GGLS track behind his 0-4-0. From "The North American Live Steamers", January 1956.

Argue Anyone??

The North American Live Steamer, Volume 1 Number 5, 1956

Well, The North American Live Steamer No. 4 has arrived, running a bit late, but it's understandable from the editor's note on page two. It's too bad so many fellows are such skeptics. They say, "wait and see" (if it lasts) which is the very thing that kills it.

Your idea of stretching it out to longer intervals will certainly help your situation, but will have a detrimental effect in getting new subscribers. I'm not kicking though, as I know what you're up against.

To start a little argument (in all respect to Mr. Coventry) on page 11 of No. 4 he considers tubes and heating surfaces. He says it is a mistake to crowd in too many at the expense of the flue area.

Mr. Coventry is one of the few who recognize flue area at all, but he starts from the wrong end. The correct way, which is full size method, is to get the correct length to tube diameter in order that all the heat may be extracted from the flue gasses. The longer the tube, the larger it can be. It works on a ratio of length to cross sectional area. In model practice in 3/4 inch scale a 3/8 inch O.D. tube will suffice for all but the largest engines. The shortest 3/8 inch tube desirable is 6 inch which if the diameter were increased to 3/4 inch i.e., 4 times the cross sectional or flue gas area the shortest desirable tube would then be 4x6=24 inches. An engine with 3/8 inch tubes 8 inches long is a good steamer, not wasting much heat up the stack when driven hard and tubes of 3/8 inch up to 11 inches long are practical, but the extra 3 inches at the smoke box end makes hardly any steam as the heat has already been extracted in the first 8 inches of the tube.

Now we come to long boilers. When the tubes are long it is better to add a combustion chamber to the firebox rather than add useless length to the tubes for, as Mr. Coventry says, a square inch of surface in a firebox is equal to 5 square inches in tubes.

Now to flue area. If you put in as many tubes as you can get, you'll have enough flue area. I'll not start an argument on superheaters. Suffice to say that none of the best steaming engines in the club here have superheaters. They have as many tubes as possible to get lots of gas area. The draft can really pull on the grate so we get a hot fire.

I have a little switcher with 4 inches diameter boiler which is an exceptionally lively steamer, and which for a long time was run with one row of tubes plugged to stop her steaming so violently when driven by visitors. Also, an engine won't steam if she has too large a grate area.

Enclosed is the first photo of our V.S.M.E. standard 4-6-0 3/4 inch scale engines. It was built as a joint effort by Mr. Jack Shaw and myself to my design with castings from my patterns. It is not super detailed, as Mr. Shaw, being a marine engineer, had very little time. It has taken about six years as it is, but really is a very easy engine to build. It has individual coil springs to the driving axle boxes which, though inferior to equalizers, it made the job a lot simpler. The cylinders are separate and bolted to the frames as in English loco practice.

The dimensions are as follows:

- Weight, about 70 pounds

- Cylinders, 1-1/4 by 1-3/4 inches

- Slide valve, travel 3/8 inch, ports 1/8 by 1 inch

- Exhaust 1/4 by 1 inch

- Driving wheels 4-1/4 inch

- Bogie wheels 1-3/4 inch

- Tender wheels 2 inch diameter

- Valve gear, Walschaert with box links

the valve gear, connecting and coupling rods, crossheads cylinder cover jackets and running boards are made of dural. Rods are bronze bushed.

Boiler is 4-1/2 inch diameter at the smokebox end tapering to 5 inch at the throat plate, tapering down again to the backhead. Tubes 3/8 inch by 8 inch long, 28 in number. Combustion chamber 2-1/2 inch long, grate area is 2-1/4 inch wide by 6 inch long. Blower jet No. 75 drill. Exhaust nozzle 3/16 inch. Fittings, steam and water gauges, blower and injector valves. Feed is by one L.B.S.C. type injector only. No hand or axle pumps. Throttle is a poppet valve with a metering pilot which gives very smooth starts. It is located in the smoke box. Tender has a metal clad wooden body enclosing a two quart copper tank. The front truck carries no weight, as the tender is carried at the front end through the coupling by the engine drag beam for extra adhesion weight. Minimum curve radius is 10 feet. Cost $60.00.

- Cliff Blackstaffe

- 1076 Colville Road

- Victoria, B.C., Canada