Bill Oberpriller's Minnie

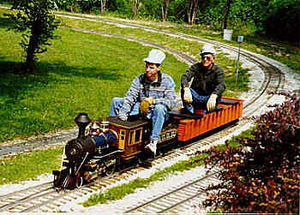

Minnie 2 is a freelance 2-4-2 live steam locomotive designed by Bill Oberpriller.

Bret Kueber

Bret Kueber published the following photos of his version of Minnie-2 in 2000.

- Bill Oberpriller provided us with fantastic tech support via Email, and his products are first rate. Allen Models, What can I say, Gene has been extremely helpful, and my order ALWAYS arrived promptly. We never had a problem with any of the castings we purchased from him.

- # 13 (2-4-2) Coal Fired Columbia Class steam locomotive (Built 5/1999)

Jim Cook

Jim Cook published the following build log for his Minnie-2 in 2002.

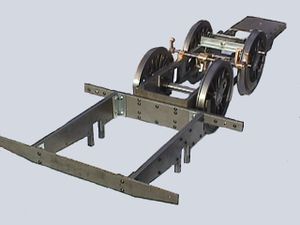

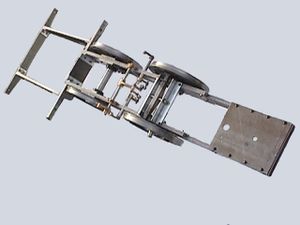

Frame

This design first appealed to me because of its general shape. To me, it looks as if it is an engine from the last half of the 1800's. The diamond stack, large headlight and cow catcher gives it character.

From a first time builder's point of view, the 2-4-2 configuration fits well. All the castings will be from the tried and true Allen Models. The designer is attempting to reduce the number of parts. This should help keep the cost and time necessary to build the engine down.

I purchased the first kit. It is for the frame. The quality of the punched parts is very good. I was able to put both side rail together during a Saturday. The rear bearing housing, front bearing housing and equalizer and the front and back frame spacers have been received and completed. In the first picture you can see the front axle mounted in the equalizer bearing boxes.

The second picture shows the rear axle in their bearing boxes. These boxes are attached directly to the frame.

Note that the the axles (1 inch diameter) were machined on the ends to accept the drivers at this time.

I ordered the four driver bearing assemblies from a local bearing supplier and received them within a few days. The castings were ordered from Allen Models. I received all the wheels and valve rough castings by the end of October.

This is a view of the frame as of the end of the second week in December. The drivers have been machined and mounted on the axles. This is taken from the rear right.

I am now working on the valve gear. I have not finished the four eccentrics and straps. I have a Sherline lathe and mill that I use for the small stuff. I just got a 9 inch swing Jet lathe and I'm setting this up for the larger items.

To give you an idea of scale, the main drivers are 8.5 inches in diameter. I was able to turn these on my friend Jerry Johnson's large lathe. He also helped me broach the key slot and quarter the wheels.

The trailing truck has a nice set of spoked wheels whose axle runs in Oilite bearings. There is plenty of movement, left and right and up and down.

Boiler

Here the boiler has been set in place. There is a plate welded to the front face of the fire box that anchors it to the frame. The front portion of the boiler has a sliding fit into the smoke box. This allows movement of the boiler as it expands and contracts.

Note the fittings at each lower corner of the firebox. This will allow proper cleaning of the mud ring.

The smoke stack has been mounted but the top half has not been machined.

Ron Thibault

Ron Thibault published the following build log for his Minnie in 1998.

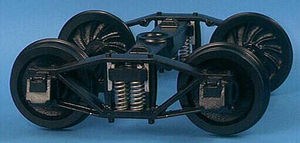

Tender Trucks

After talking to Bill, I decided to start construction of the engine with the tender trucks. He recommended Cannonball's Archbar trucks. After also looking at other companies castings, I agree! Cannonball has a good reputation, and their kit is also the least expensive! I like that combination!! The complete kit with all materials required is only $175.00 (they are also available RTR at $355.00). In addition I will order a wheel gauge template for 7.5" track, and the 29/32" drill needed for the bearing pockets. The drill is a standard drill that you can get elsewhere, if you desire. This brings the total to $199.00 plus about $10.00 shipping. Figure 1 is the picture of a completed truck from Cannonballs catalog. Note: My wheels are the plain back type rather than the fluted ones. This made machining for a novice (me) a little easier and should not be noticeable on the finished tender. In addition the trucks can be built with a lathe, drill press, and file. I do not have a milling machine, so this combination fits my available resources.

When I was inspecting the parts after they arrived I noticed that the lower "bar" on the cast frames was much thinner than the other "bars". This seemed strange, I have not noticed this in pictures of other company's kits which I thought had all the bars the same thickness. I pulled out my copy of Meyer's "Modern Locomotive Construction 1892" and looked up tender trucks. Lo and behold, the trucks in the book also had thinner lower bars!! So these castings are quite prototypical! The rest of the parts were all of good quality, with no visible defects.

Exploded drawing of Cannonball Ltd archbar trucks.

Video

<videoflash>xZ3aow8QRvg</videoflash>

<videoflash>wYhdnZqN_lM</videoflash>