Balanced Air Brakes from Scratch: Difference between revisions

| (9 intermediate revisions by the same user not shown) | |||

| Line 8: | Line 8: | ||

This is my first attempt at building operating air brakes, and I am quite pleased with the results. Air brakes will certainly be added to my other equipment. | This is my first attempt at building operating air brakes, and I am quite pleased with the results. Air brakes will certainly be added to my other equipment. | ||

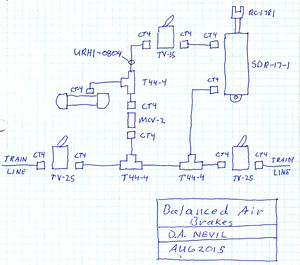

<i>Summary: This article describes how to build [[Air_brakes#Pull_to_Apply|Pull-to-apply balanced air brakes]].</i> | |||

== Equipment == | == Equipment == | ||

| Line 35: | Line 37: | ||

=== Air Tank === | === Air Tank === | ||

<gallery widths="300px" heights="300px"> | <gallery widths="300px" heights="300px" perrow="2"> | ||

File:FreightTruckAirBrakes1.jpg|I started with the air tank. It is constructed using 2 inch diameter PVC pipe (schedule 40) with a pair of caps. A hole was drilled and tapped for 10-32 threads to accept a Clippard fitting. An adhesive dot was placed over the hole before painting. | File:FreightTruckAirBrakes1.jpg|I started with the air tank. It is constructed using 2 inch diameter PVC pipe (schedule 40) with a pair of caps. A hole was drilled and tapped for 10-32 threads to accept a Clippard fitting. An adhesive dot was placed over the hole before painting. | ||

File:FreightTruckAirbrakes2.jpg|PVC glue was applied to the threaded hole before inserting the Clippart CT4 1/16 hose barb fitting. Be careful with the glue. As you can see it will remove paint. | File:FreightTruckAirbrakes2.jpg|PVC glue was applied to the threaded hole before inserting the Clippart CT4 1/16 hose barb fitting. Be careful with the glue. As you can see it will remove paint. | ||

| Line 50: | Line 52: | ||

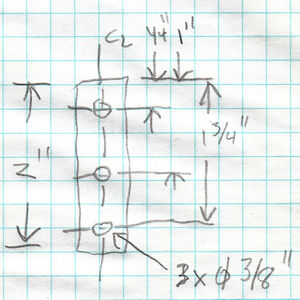

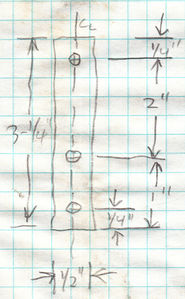

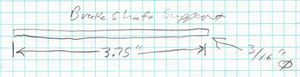

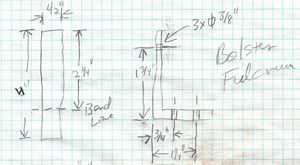

=== Mechanical Drawings === | === Mechanical Drawings === | ||

<gallery widths="300px" heights="300px"> | <gallery widths="300px" heights="300px" perrow="2"> | ||

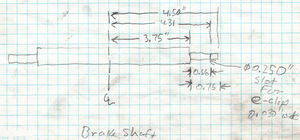

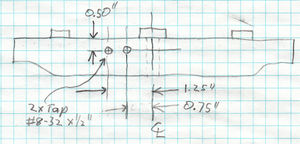

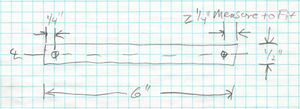

File:CabooseBrakes BrakeShaft.jpg|Brake Shaft for Caboose Trucks. Two required per truck. | File:CabooseBrakes BrakeShaft.jpg|Brake Shaft for Caboose Trucks. Two required per truck. | ||

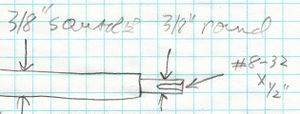

File:CabooseBrakes BrakeShaftDetail.jpg|End detail of Brake Shaft. Turn ends down to 3/8 inch on lathe. Drill and tap for 8-32 threads 1/4 inch deep. | File:CabooseBrakes BrakeShaftDetail.jpg|End detail of Brake Shaft. Turn ends down to 3/8 inch on lathe. Drill and tap for 8-32 threads 1/4 inch deep. | ||

| Line 67: | Line 69: | ||

=== Assembling Brake Shafts === | === Assembling Brake Shafts === | ||

<gallery widths="300px" heights="300px"> | <gallery widths="300px" heights="300px" perrow="2"> | ||

File:CabooseTrucks TurningBrakeShaft.jpg|Turning one end of a Brake Shaft. | File:CabooseTrucks TurningBrakeShaft.jpg|Turning one end of a Brake Shaft. | ||

File:CabooseBrakes TestFit.jpg|File:CabooseBrakes TestFit.jpg | File:CabooseBrakes TestFit.jpg|File:CabooseBrakes TestFit.jpg | ||

| Line 77: | Line 79: | ||

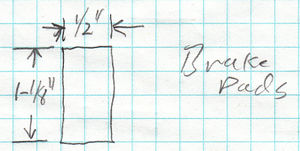

=== Brake Pads === | === Brake Pads === | ||

<gallery widths="300px" heights="300px"> | <gallery widths="300px" heights="300px" perrow="2"> | ||

File:CabooseTruck BrakePadMaterial.jpg|Brake pad material from McMaster-Carr. | File:CabooseTruck BrakePadMaterial.jpg|Brake pad material from McMaster-Carr. | ||

File:CabooseTrucks AttachingBrakeShoes.jpg|The Brake Pads are cut and glued to the aluminum Brake Shoes with JB Weld. The Brake Shafts are pulled tight using rebar ties attached to the axle. This holds the shoes tightly to the pads and forms the curve in the shoes. | File:CabooseTrucks AttachingBrakeShoes.jpg|The Brake Pads are cut and glued to the aluminum Brake Shoes with JB Weld. The Brake Shafts are pulled tight using rebar ties attached to the axle. This holds the shoes tightly to the pads and forms the curve in the shoes. | ||

| Line 84: | Line 86: | ||

== Final Assembly == | == Final Assembly == | ||

<gallery widths="300px" heights="300px"> | <gallery widths="300px" heights="300px" perrow="2"> | ||

File:BalanceAirBrakes for Caboose FinalAssembly.jpg|The trucks with balanced air brakes are assembled onto the undercarriage of the caboose, along with air brake cylinder, reservoir and air switches. | File:BalanceAirBrakes for Caboose FinalAssembly.jpg|The trucks with balanced air brakes are assembled onto the undercarriage of the caboose, along with air brake cylinder, reservoir and air switches. | ||

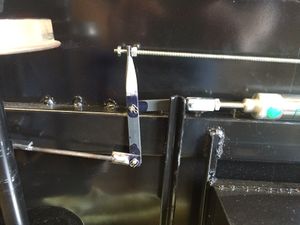

File:CabooseAirBrakeRiggingSupportBracket.jpg|Support brackets made from flat brass stock were added to keep the levers in place. Nylon lock nuts were later used on both sides of the lever. | |||

File:CabooseAirBrakeRiggingLeft.jpg|The brake rigging was kept as simple as possible. This view shows the rigging attached to the plunger of the air cylinder. | File:CabooseAirBrakeRiggingLeft.jpg|The brake rigging was kept as simple as possible. This view shows the rigging attached to the plunger of the air cylinder. | ||

File:CabooseAirBrakeRiggingRight.jpg|This view shows the rigging attached to the body of the air cylinder. Note that the air cylinder is supported solely by the brake rigging. | File:CabooseAirBrakeRiggingRight.jpg|This view shows the rigging attached to the body of the air cylinder. Note that the air cylinder is supported solely by the brake rigging. | ||

File:CabooseAirBrakeTrainLineValve.jpg|Clippard TV-2S toggle valves were selected because of their small size, low cost, and reliable operation. Note the eye hooks for safety chains, as required by some railroads. | File:CabooseAirBrakeTrainLineValve.jpg|Clippard TV-2S toggle valves were selected because of their small size, low cost, and reliable operation. Note the eye hooks for safety chains, as required by some railroads. | ||

</gallery> | </gallery> | ||

=== Plastic Shoes === | |||

In 2019 I replaced the aluminum shoes with more realistic shoes printed in black PLA. See [[Brake_shoe#Plastic_Brake_Shoes|Plastic Brake Shoes]]. | |||

== Video Demo == | == Video Demo == | ||

| Line 97: | Line 103: | ||

<br> | <br> | ||

< | <youtube>6xFOI4LY6Vs</youtube> | ||

<br><br> | <br><br> | ||

== External Links == | |||

* [http://212steam.blogspot.com/ Brake shoes from ring stock] | |||

Latest revision as of 23:20, 5 January 2021

Fall 2015

During the summer of 2015 I began studying air brakes and how live steam modelers incorporate working air brake systems on their trains. I was well into building a Kitsap Live Steamers caboose kit and decided to add a fully operational balanced air brake system to the caboose.

This is my first attempt at building operating air brakes, and I am quite pleased with the results. Air brakes will certainly be added to my other equipment.

Summary: This article describes how to build Pull-to-apply balanced air brakes.

Equipment

- Clippard parts:

- UDR-17-1 : Stainless steel double-acting cylinder, 1 inch stroke, 1-1/16 inch bore, 5/16 inch shaft

- CT4 : #10-32 to 1/8” ID Hose Connector, designed for Clippard's Polyurethane hose

- T44-4 : Tee fitting, 1/8 inch ID

- URH1-0804-BKS : Urethane tube 1/8 inch ID

- TV-3SP : 3-Way Toggle Valve, ENP Steel Toggle, 1/8" NPT

- MCV-2 : Check Valve, #10-32 Ports

- 15090-1 : 1/8” NPT to #10-32 “L” Fitting

Tools and Supplies

The following tools were used in the construction of the truck brakes:

- Drill Press

- Low-cost wire welder (110 Volt AC) from Harbor Freight

- Lincoln Innershield NR-211-MP flux core welding wire, 0.035 inch

- Lathe (for turning brake shoes and brake shafts)

Build Gallery

Air Tank

Brake Shoes

In an effort to save money I decided to cut brakes from a ring of aluminum purchased from McMaster-Carr. The pipe has a 4 inch inside diameter and a 6 inch outside diameter.

A 1/2 inch width of the aluminum pipe was parted off on the lathe. Here it has been blued and marked for cutting.

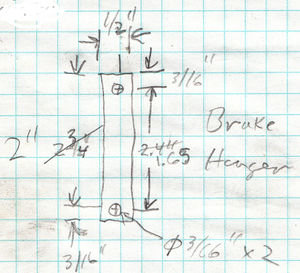

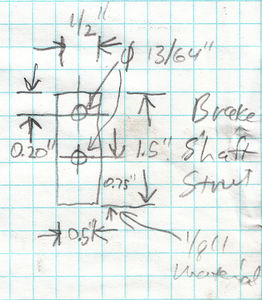

Mechanical Drawings

Assembling Brake Shafts

Brake Pads

Final Assembly

Plastic Shoes

In 2019 I replaced the aluminum shoes with more realistic shoes printed in black PLA. See Plastic Brake Shoes.

Video Demo

This video demonstrates the failsafe operation of the balanced brakes, along with how to disable the brakes once activated. Video by Daris A Nevil, August 2015.