Automatic Blower Valve: Difference between revisions

(Created page with "Category:Steam Locomotive Parts Category:Construction thumb|center|500px The above automatic blower valve is being used wi...") |

No edit summary |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Steam Locomotive Parts]] | [[Category:Steam Locomotive Parts]] | ||

[[Category:Construction]] | [[Category:Construction]] | ||

== Fred E. Wise == | |||

From <i>[[The Live Steamer]]</i>, November 1951 | |||

[[File:FredWise AutomaticBlowerValve.png|thumb|center|500px]] | [[File:FredWise AutomaticBlowerValve.png|thumb|center|500px]] | ||

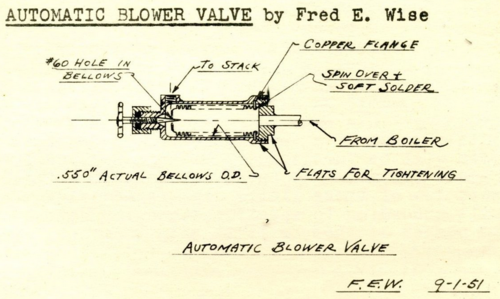

The above automatic blower valve is being used with remarkable success on my 3/4 inch scale Atlantic. The valve is small and easy to construct and may be mounted most anyplace in the cab. The brass bellows may be obtained from Fulton Sylphon Co., Knoxville, Tenn., and is listed in their bulletin No 1300. Their reference No. is 1002* having 26 convolutions, solid end, single ply with maximum working pressure of 185 pounds per square inch. The nomimal [[OD]] is 9/16" but actually is only 0.550 inch [[OD]] which makes it work perfectly in a 9/16 inch hole. The pipe leading to the stack must be large enough to reduce the back pressure on the bellows. I used 1/8 inch [[ID]] tubing with no reduction in area at the stack end. Another critical part is the valve angle, but this is easy to change. I found a 12 degree included angle the best. (Note: Sorry there was not enough space this issue to also give sketch and details of Mr. R.E. Thompson's type of automatic blower). | The above automatic blower valve is being used with remarkable success on my 3/4 inch scale Atlantic. The valve is small and easy to construct and may be mounted most anyplace in the cab. The brass bellows may be obtained from Fulton Sylphon Co., Knoxville, Tenn., and is listed in their bulletin No 1300. Their reference No. is 1002* having 26 convolutions, solid end, single ply with maximum working pressure of 185 pounds per square inch. The nomimal [[OD]] is 9/16" but actually is only 0.550 inch [[OD]] which makes it work perfectly in a 9/16 inch hole. The pipe leading to the stack must be large enough to reduce the back pressure on the bellows. I used 1/8 inch [[ID]] tubing with no reduction in area at the stack end. Another critical part is the valve angle, but this is easy to change. I found a 12 degree included angle the best. (Note: Sorry there was not enough space this issue to also give sketch and details of Mr. [[R.E. Thompson]]'s type of automatic blower). | ||

== Sources of Bellows == | |||

* [http://www.sigmanetics.com/pdfs/bellows.pdf Sigma-netics] | |||

* [http://www.supaflex.com/supaflex-products/copper-expansion-bellows.html Supaflex] | |||

* [http://www.ameriflex.net/bellows.php Ameriflex Inc] | |||

Latest revision as of 09:57, 27 January 2020

Fred E. Wise

From The Live Steamer, November 1951

The above automatic blower valve is being used with remarkable success on my 3/4 inch scale Atlantic. The valve is small and easy to construct and may be mounted most anyplace in the cab. The brass bellows may be obtained from Fulton Sylphon Co., Knoxville, Tenn., and is listed in their bulletin No 1300. Their reference No. is 1002* having 26 convolutions, solid end, single ply with maximum working pressure of 185 pounds per square inch. The nomimal OD is 9/16" but actually is only 0.550 inch OD which makes it work perfectly in a 9/16 inch hole. The pipe leading to the stack must be large enough to reduce the back pressure on the bellows. I used 1/8 inch ID tubing with no reduction in area at the stack end. Another critical part is the valve angle, but this is easy to change. I found a 12 degree included angle the best. (Note: Sorry there was not enough space this issue to also give sketch and details of Mr. R.E. Thompson's type of automatic blower).