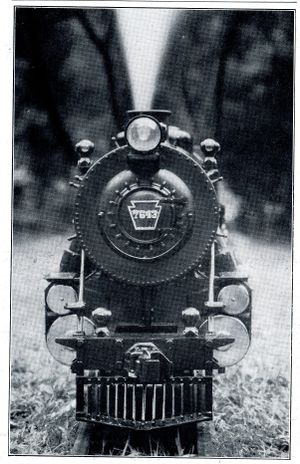

A P.R.R. K4s Locomotive

A P.R.R. K4s Locomotive

1-1/2-in Scale - 7-in. Gauge

By Mr. W. Edmunds Spon

The Modelmaker

September 1932

Through the courtesy of Mr. Calvert Holt the builder of this locomotive I had the opportunity of not only seeing this fine miniature locomotive under steam but of making a number of trips on the flat car, with the builder who did the driving.

As the tender was in the shop being finished up a flat car about six feet long mounted upon two four wheel trucks was coupled up to the locomotive for the driver and passengers to ride upon.

The trials were run over a track consisting of standard factory track rail laid to a 7" gauge and well spiked down to substantial ties laid upon the ground. This track commenced at the entrance door to his shop down an 8 per cent grade around a 75 radius curve to a starting place under the trees. A total distance of about one hundred and fifty feet.

To get up steam Mr. Holt attached a pipe from the air compressor in his shop to the locomotive's blower. Then he placed some kerosene soaked lighted rags into the fire-box with some charcoal and Ford briquetes and in about fifteen minutes the gauge showed about sixty pounds of steam a few minutes later the pressure reached ninety pounds and one of the safety vales lifted.

We took our seats upon the flat car and the driver backed down to the end of the track. He then started her forward at a slow speed the locomotive taking the curve and the grade very easily and steadily.

Other runs were made at varying speeds and then one from a stop at the bottom of the grade. The locomotive took the grade easily picking up speed at every foot travelled.

In the final test the driver started from the end of the track and gradually opened up wide, she took the curve with an easy swinging motion at a fast clip but was quickly and smoothly stopped with the steam brakes before the end of the track was reached.

The locomotive was quick in taking steam and ran with very little vibration in spite of the track being a bit rough in places. This showed how well balanced she was and the ease with which the springs took up the jolts from the track.

Mr. Holt said that special care had been taken to make the insulation around the boiler as perfect as possible and in consequence the locomotive could stand for a considerable time after a run without the boiler losing much heat. In fact it only required a minute or two with the blower on, after such a stand, to make the safety valve lift.

The two safety valves are set to blow off at ninety pounds. The tests under steam showed the splendid workmanship and care that had been exercised in her construction.

Mr. Holt's only regret was that he had not the opportunity of making a run on at least a mile of well laid track so he could have really seen what she could to.

Notes on Construction

This locomotive was built from drawings made by Mr. Berthold Audsley scaled down from a set of shop drawings procured from the builders of the prototype.

During the progress of the work some slight alterations and changes were made to the original design.

The cylinders were very carefully bored to size and the inside walls finished off to a high polish.

Each piston is fitted with two rings and each piston valve has four rings.

The side frames were cut out of cold rolled bar steel 3/4" x 5", 62" long.

All the wheels are of cast steel. The six drivers were turned down below size and steel tyres shrunk on.

The drivers are fitted with leaf springs, made for 1/16" thick spring brass, 13 leaves to a spring and set on hangers with the regulation hanger pins.

Roller bearings are fitted for the drivers. These bearings are packed in grease with felt pads well soaked in oil.

All the main and side rods have bronze floating bushings with oil reservoirs.

Standard brake rigging is fitted to the main frame in the usual way with a brake shoe to each driving wheel.

Brass grease cups are fitted where necessary, according to regular standard practice.

The pony truck and trailer frame are both fitted with spiral springs and ball bearings with regulation greas boxes filled with grease and packed with waste.

The oil pump for lubricating the cylinders is fitted on the left side of the loco and is operated with a gear movement on the end of a bar attached to the cross head. By this means oil is supplied to the steam supply pipes to cylinders. There is a drifting valve to each cylinder.

Two check valves are attached to the left side of the boiler, one for the Birch pump and the other for the injector. another check valve is attached to the right side of the boiler for the other injector.

The Birch compound water pump 1-1/8" x 11/16", is a fine piece of work. it is placed on the left hand side of the boiler and has its own line connection to the water tank. On a test out, the pump registered a water pressure of 210 lbs. on a 70 lb. head of steam. A very excellent performance.

The two injectors, capacity four quarts to a minute, are placed one on each side of fire-box and each has a separate line connection to the water tank.

The copper boiler was made in England and all tubes are expanded. In England it was given an hydraulic pressure test to 300 lbs. per sq. in. Mr. Holt tested it under steam to 145 lbs. per sq. in.

The tender is six feet six inches long. The tank has a holding capacity of twenty gallons of water, while the coal bunker will take fifty pounds of fuel. A seat is fitted over the front of tender for the driver. There are also three wheel valves for the water lines.

The tender is mounted on two four wheel trucks, which are fitted with spiral springs, ball bearings and regulation grease boxes and a brake shoe to each wheel.

The boiler fittings include steam dome, sand dome, bell, dummy lighting generator and head light with electric bulb. Side and front hand rails and foot boards.

The four marker lamps each contain four glass lenses and an electric bulb.

Regular pattern cowcatcher and steps.

Motion is all bright. The painting is a fine job, boiler sage green and the rest of loco and tender dull black.

Specifications

- P. R. R. K4s 4-6-2

- Scale, 1-1/2", gauge 7"

- Cylinders, 3" bore, by 3-1/2" stroke

- Piston Valves, 1-5/16" bore by 7/8" travel

- Driving wheels, 10" dia

- Pony wheels, 4-5/16" dia

- Trailer wheels 6" dia

- Tender wheels, 3-1/2" dia

- Main frame 3/4" by 5", 62" long

- Trailer frame, cast iron

- Boiler, all copper

- Size, 5' 6" long, 30" dia, 1/4" thick

- Superheater, 6 tubes, 1" dia 3/16" thick

- 20 tubes, 3/4" dia 3/16" thick

- Combustion chamber, 8" long

- Fire grate, 9" by 18", 171 sq inches

- All plating 1/4" thick

- Total heating surface 24-1/2 sq feet

- Steam pressure, 90 lbs

- Wheel base, 39"

- Length of engine, 72"

- Height from rail to top of smoke stack, 22-1/2"

- Width of Engine, 15"

- Length of tender, 6' 6"

- Length of Engine and tender, 12' 6"

- Tender body made from sheet brass, 1/16" thick

- Walschaert valve gear

- Two steam brakes, 13/16" by 1-1/8", leverage increase 5 to 1

- Automatic oil pump

- Two injectors

- Birch compound steam pump

- Three check valves

- Two safety Vales

- Two drifting valves

- Sand dome

- Steam dome

- Dummy lighting generator

- Head light

- Four marker lights

- Working bell

- Standard automatic couplers

- Cab fittings

- Throttle

- Reversing leve

- Brake lever

- Water glass

- Steam pressure gauge

- Five wheel valves

- Approximate 10 H.P.

- Fuel, Ford briquetes

- Estimated maximum speed, 30 m.p.h.

- Engine has already run about 5 miles and operates perfectly