A New Design for Piston Valve Locomotive Cylinders

A New Design for Piston Valve Locomotive Cylinders

The Modelmaker, Volume 9, Number 10, October 1932

The need for a design of cylinder that should have its steam and exhaust passages all cored in has long been felt by American modelmakers because although the alternative of drilling can be made fairly successful, port areas are necessarily limited and of course holes at right angles to each other are encountered, resulting in sharp angular turns decreasing the efficiency.

The design illustrated is the result of many experiments, and is found to be eminently successful.

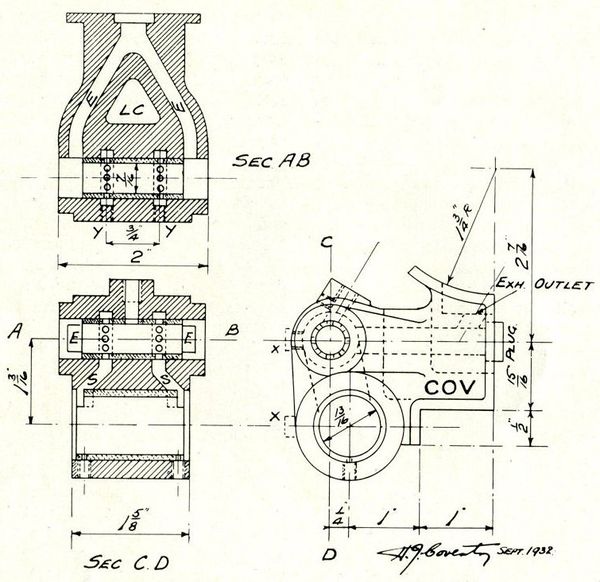

Referring to the drawing, it will be noticed that full size practice is reproduced in principle, and in Sections AB and CD, the exhaust passage is clearly shown at E. The end of the passage at the central joint flange of cylinder is to be plugged, which serves a dual purpose, (a) it locates each cylinder independently of the bolts and prevents the exhaust steam from one side blowing over to create back pressure on the other cylinder as it would tend to do without the plug. The final exhaust makes its escape to the blast pipe through a short drilled hole into the cored exhaust passage. The steam passages are annular recesses in the chest and continued down into the cylinder barrel. These cores are made amply wide to ensure strength and prevent them being washed away when the molten metal is poured into the mold. These are marked S in the drawing. A lightening core L.C. is provided to insure sound metal between saddle and chest.

Both the steam chest and cylinder barrel are bushed, as is done in full size practice, and the casting is bored straight through for a press fit to both bushes. The bushes may be of steel or bronze. The valve bush is to be drilled with eight 3/32 inch holes by means of a jig already described in notes by the writer on 3/4 inch scale "President Washington." It will be noticed that both bushes are made shorter than the cylinder. By this means, both bushes can be replaced if they become worn, without disturbing the fits of cylinder and steam chest heads. In the case of the steam chest the bush covers the distance between exhaust passages only as the valve does not travel beyond the end of the bush and a very free exhaust is obtained.

The castings are of gray iron, suitable for superheated steam. If steel bushes are used Sumet bronze is excellent material for pistons and valves, or if bronze bushes are used, stainless steel or cast iron may be used for these parts. Strips at XX are provided on castings to facilitate marking out and machining, which may be done by methods already described by the writer and others in the pages of "The Modelmaker."

A valuable feature of this design is the possibility of using the regular orthodox "peep hole plugs" whereby the valve can be seen for setting purposes, these are shown at YY.