A Loco Built From Scrap

3/4 inch Scale Switcher

by C. J. Van Gorp

The Miniature Locomotive, September-October 1953

At this length it may seem like a chiseler's method of obtaining material to construct a locomotive. However in this region where steel is one of the main products, it is also one of the most difficult items to buy in small quantities. Priorities, due to the war didn't help matters either.

Fortunately, of all the places where discarded or scrap steel pieces were obtained, the purchase price was refused after learning that a little live steam locomotive was under construction.

Since the completion of the engine there seems to be no end to the offer of scrap pieces from these places. A great deal of learning is in store when you make it from scrap, but there is a greater gain when you make friends.

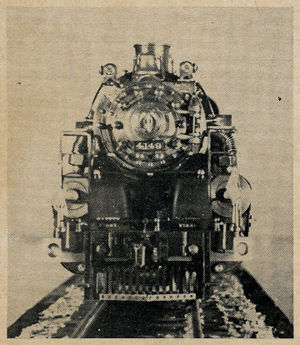

In the fall of 1949, after having completed a 1/4 inch scale 4-8-4 Southern Pacific engine from castings purchased from Martin Lewis the fruit of eight years' work was ripe. She could pull a load far beyond her own weight in adhesion, but there was a worm in the fruit. Being spirit fired gave a fire hazard for indoor operation, and curve radius offered a problem. Most of all the right of way from the lock washer on the third finger of the left hand was needed.

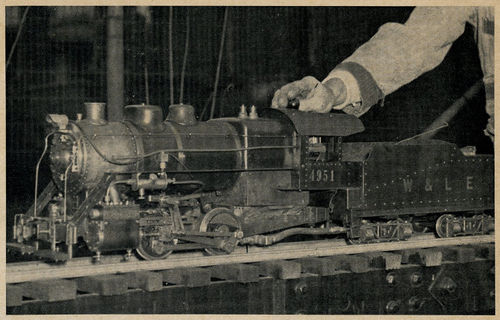

That same fall of 1949 a set of drawings were acquired from George Taylor of Pompton Lakes, N. J., regarding a 3/4 inch switcher called Little Lulu. Brother Taylor is tops when it comes to live steam. He made the first engine of this type (an 0-4-0 job) that can lick the radius worm, burn coal, smell and grunt like an engine should, and pull six to eight men. Man, that's an engine!

Having only a 6 inch Atlas lathe and a second hand drill press at the time, the scrap pile was raided, and the frames came from two pieces of cold rolled stock 1/4 by 2 by 20 inch. These came from a friend's rejected idea for a power mower. The axles were turned from pieces of drill rod that at one time were shafts of a high speed pump. Bearings were specified as the regular bronze block type. An improvement was made by inserting a set of needle bearings from parts of an old adding machine.

Cylinders and pistons were cut from blocks of mehanite iron having steam chests of 1 by 2 inch bar stock rough drilled and finished, filed to form the box. These at one time were used to form candy on a marble surface.

Rods and crossheads were solid, cut from bars that were used to space or shim dies at a local forging plant.

The smoke box was once a coupling for a 4-1/2 inch underground gas main. The threads being bored out to fit the boiler. A 1/16 inch cut on the O.D. made it fit the saddle and stack.

The front door is cut saucer shape from 3 inch bar stock, having clamps and bolts on the first step of the outside face. When closed in and against the ring it is held in place with a 1/8"-40 bar screwed into a 1/8 inch by 1/2 inch bar inside the smoke box. The clamps and bolts come along with the door as it is opened. Hinges are inlaid into the door by slotting the door with a 1/8 inch keyway cutter. The rivets are linoleum tacks or escutcheon pins. This item was to be a casting as to the drawings.

Feed water pump is front axle driven, having two eccentrics driving their little plungers into the pump body located between the frame and axles. Most of these parts were cut from bronze pieces from broken bearings or heavy bushings.

All nuts and bolts used in the construction of the chassis were, at one time, Allen wrenches. By annealing in a gas flame they can be machine very easily and rehardened by reheating and quenching in cold water.

The boiler was one started for a customer of T. Goodhand of England. This was the only item of price to complete the little engine. It was made without the opening fro the throttle, and it offered a challenge to put in a plug type throttle that would not leak. But a good boiler is hard to pass up and a lot of work could be saved. This item was inexpensive and the Pound Sterling had dropped to an all time low.

Boiler lagging is from furnace material, the cover over the pop valves and firebox was cut from the switch box of an old monitor top refrigerator.

The tender is all brass plate from the lower panels of kitchen doors that were once in a mansion. Water chamber houses a hand pump and screens for the axle pump lines. Capacity of tender is 2-1/2 gallons of water, 3 pounds of coal.

Our track is of elevated type, 150 feet in a pear shape oval. It is located in the back yard and is at the disposal of any live steamer having 3-1/2 inch gauge equipment.

Oh yes, the right of way was settled by eliminating the clothes lines. What a guy won't do for his wife (or an engine). We bought a clothes dryer.