Simplun: Difference between revisions

(Created page with "Category:Construction Simplun ''A 4-4-0 Story in Pictures'' by W. VanBrocklin, Jr. Pine Street Dover, Mass. This 3-1/2 inch gauge engine was...") |

No edit summary |

||

| Line 4: | Line 4: | ||

''A 4-4-0 Story in Pictures'' | ''A 4-4-0 Story in Pictures'' | ||

by [[Bill | by [[Bill Van Brocklin|W. VanBrocklin, Jr.]] | ||

Pine Street | Pine Street | ||

| Line 10: | Line 10: | ||

Dover, Mass. | Dover, Mass. | ||

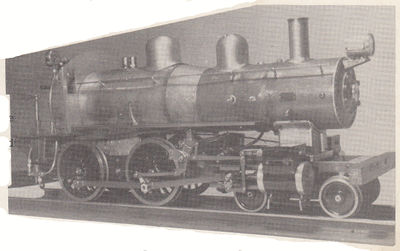

This 3-1/2 inch gauge engine was built with two objects in mind, one | This 3-1/2 inch gauge engine was built with two objects in mind, one extreme simplicity and the other consistent reliability. After many tests in the last six months, these two objects were proved on the track. It is a free lance job, but in keeping with engines built around 1900-1920. One of the disadvantages of the eight-wheel types in smaller gauges is not enough weight on the drivers. In full size this is approximately 50% weight on drivers and 50% on pilot truck. In the little one this was greatly improved, the total engine weight being 40 pounds, of which 30 pounds are on the drivers. Side bar equalizing on the axle boxes and pilot touch frame side pivots make for good tractive effort, and on steel track tests with ball-bearing trolley she will pull 400 pounds, or 10 times her own weight without much effort. At one test on a 2% grade she hauled two adults up on 40 pound boiler pressure. | ||

The engine is remarkably free from slipping with proper throttle starts and boiler capable of | The engine is remarkably free from slipping with proper throttle starts and boiler capable of maintain all cylinder needs. Originally the boiler was built with eighteen 3/8 inch diameter and two 3/4 inch diameter tubes, and it was found the two bottom tubes frequently got blocked with cinders, so they were stopped up with brass plugs. This has made no difference to steaming and gave a better depth of fire, about 1-1/2 inch to top of grate. | ||

The [[Walschaert valve gear]] gives good steam distribution and the best running position is two notches off center. It is of box link side pivot construction and as yet no signs of wear have been noticed. The reverse lever is unorthodox in that there is no latch. The lever carries a 1/8 inch ball and stiff compression spring behind it, the ball seating in indents in the quadrant. So far it has never loosened up and holds the gear in each position without shake. | The [[Walschaert valve gear]] gives good steam distribution and the best running position is two notches off center. It is of box link side pivot construction and as yet no signs of wear have been noticed. The reverse lever is unorthodox in that there is no latch. The lever carries a 1/8 inch ball and stiff compression spring behind it, the ball seating in indents in the quadrant. So far it has never loosened up and holds the gear in each position without shake. | ||

| Line 18: | Line 18: | ||

A true hydrostatic lubricator was tried with cab feed control as an experiment and has worked very well, although oil feed adjustment is critical, but once correctly set, the engine can be run for hours with an almost dry stack. There is no lack of lubrication as slight weeps of oil can be seen at the steam chest joints. One thing has to be remembered and that is to shut off the steam supply when stopping for any great length of time. The cab sides and roof are connected in one piece with slides on front of each side. This allows it to be pulled up and off, no screws being necessary to hold in place. The cab deck and front remain on the engine. This has been a blessing for easier plumbing makeup and cleaning. | A true hydrostatic lubricator was tried with cab feed control as an experiment and has worked very well, although oil feed adjustment is critical, but once correctly set, the engine can be run for hours with an almost dry stack. There is no lack of lubrication as slight weeps of oil can be seen at the steam chest joints. One thing has to be remembered and that is to shut off the steam supply when stopping for any great length of time. The cab sides and roof are connected in one piece with slides on front of each side. This allows it to be pulled up and off, no screws being necessary to hold in place. The cab deck and front remain on the engine. This has been a blessing for easier plumbing makeup and cleaning. | ||

An injector sent by [[LBSC]] feeds to a backhead check which gives short steam and delivery pipes. It has performed consistently and after six months service hasn't been cleaned yet. Since most of the pictures were taken a small Westinghouse pump has been fitted. This is used as a water pump and has a single cylinder, 5/8 inch bore by 3/8 inch bore water and 1/2 inch stroke. It handles water feed just ticking over (after much trial and error!) A compressed air connection is in the steam line to run the pump when | An injector sent by [[LBSC]] feeds to a backhead check which gives short steam and delivery pipes. It has performed consistently and after six months service hasn't been cleaned yet. Since most of the pictures were taken a small Westinghouse pump has been fitted. This is used as a water pump and has a single cylinder, 5/8 inch bore by 3/8 inch bore water and 1/2 inch stroke. It handles water feed just ticking over (after much trial and error!) A compressed air connection is in the steam line to run the pump when the engine is cold to fill the boiler. A similar connection is at the smokebox for blower. The blower is a single tube, 1/8 inch [[OD]] by 0.070 inch [[ID]] and is the best I have ever made, walking the "clock" up in no time at all. All in all, [[Simplum]] is one of my favorites, being very handy to carry around, especially when one has a flight of cellar stairs and three doorways to navigate through to get to the car! | ||

== Specifications == | == Specifications == | ||

| Line 40: | Line 40: | ||

* Tender contains hand pump, suction control valve and injector valve | * Tender contains hand pump, suction control valve and injector valve | ||

* Boiler pressure - 90 pounds | * Boiler pressure - 90 pounds | ||

== Photo Gallery == | |||

<gallery widths="400px" heights="400px"> | |||

File:BillVanBrocklin Simplun 1 1956.jpg|Photo by A. Milburn | |||

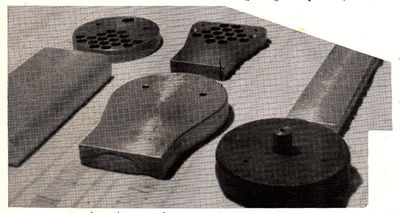

File:BillVanBrocklin Simplun 2 1956.jpg|The first stage in good boiler construction is the forms for the flanged sheets, such as tube sheets, front and back firebox heads and rear boiler head. Note drill guide holes in forms for front head and front firebox end. | |||

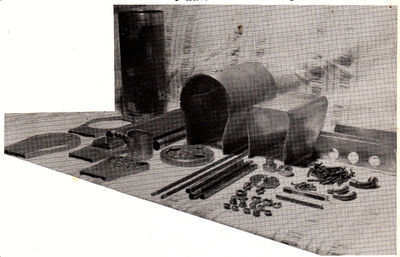

File:BillVanBrocklin Simplun 3 1956.jpg|All parts of the complete boiler just before assembly. | |||

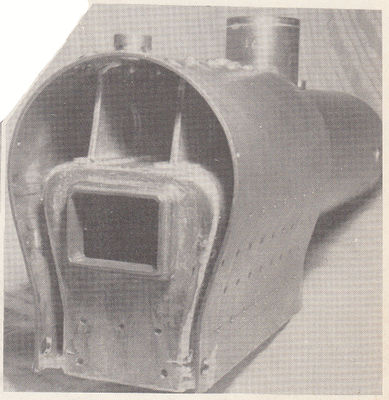

File:BillVanBrocklin Simplun 4 1956.jpg|Assembly: Firebox, Tubes, Front tube sheet, and Girders all one unit. Next will come staybolts, backhead and bushings for fittings. | |||

File:BillVanBrocklin Simplun 5 1956.jpg|Shown in this photo is the firebox and flue assembly, already silver soldered ready for insertion into the outer shell. <i>NOTE FIRST TIMERS: It will save you a little tussle if at this stage you will put the front tube sheet in position and silver solder, then slide the complete unit into the outer sheel. DON'T FORGET THE DRY PIPE!!!</i> | |||

File:BillVanBrocklin Simplun 6 1956.jpg|Here is the boiler sheel, throat sheet and crown sheet assembled, all ready for the firebox and tube assembly. | |||

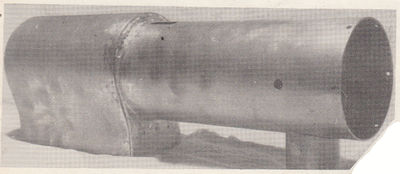

File:BillVanBrocklin Simplun 7 1956.jpg|The complete boiler. | |||

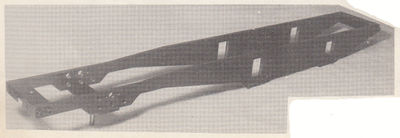

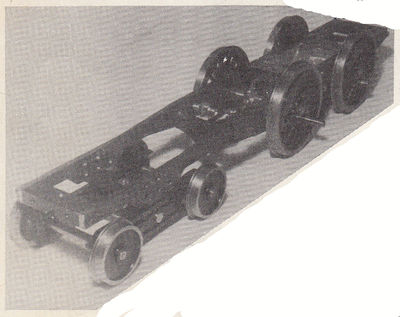

File:BillVanBrocklin Simplun 8 1956.jpg|First things first. In this instance a straight and sturdy frame upon which you can start construction. | |||

File:BillVanBrocklin Simplun 9 1956.jpg|Most times it will be best if you build and mount the axle pump while your loco is in its early stages. | |||

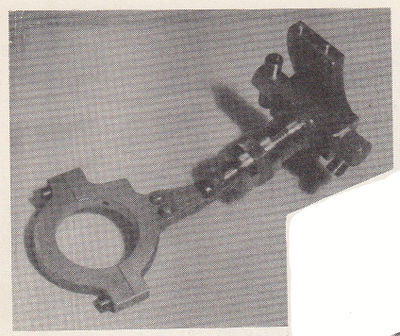

File:BillVanBrocklin Simplun 10 1956.jpg|Note the simplicity of this 4 wheeled leading truck. No swing links needed for the 4-4-0, just a pivoted center. Simple equalization takes up track variations. | |||

File:BillVanBrocklin Simplun 11 1956.jpg|Cylinders, slide valve with packed pistons. | |||

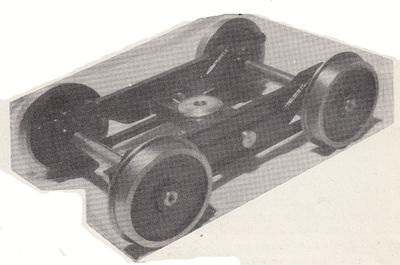

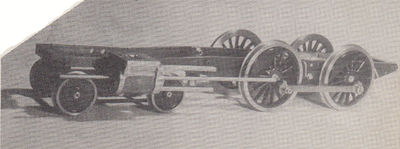

File:BillVanBrocklin Simplun 12 1956.jpg|Now we're down to business--Frames, Drivers, Front truck and axle pump in to stay. Notice all parts are painted before assembly. | |||

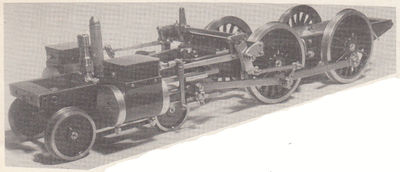

File:BillVanBrocklin Simplun 13 1956.jpg|Lining up the cylinders. Side rods have been fitted. | |||

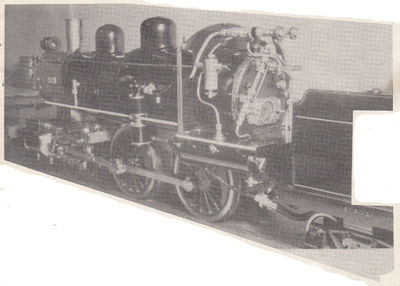

File:BillVanBrocklin Simplun 14 1956.jpg|Here we have added crossheads, main rods, steam chests, valve gear and exhaust nozzle. | |||

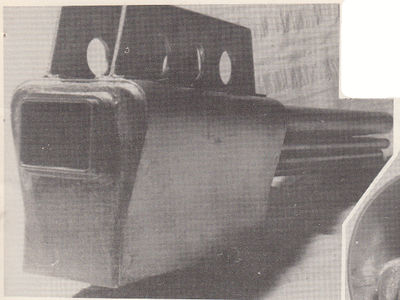

File:BillVanBrocklin Simplun 15 1956.jpg|At this stage the boiler is erected along with the smokebox, stack, domes, running-boards, buffer beam, and headlight. Note boiler lagging brings up shape to wagon top type. | |||

File:BillVanBrocklin Simplun 16 1956.jpg|Here are all of the necessities for good operation. Water column, throttle, steam pressure gauge, blower valve, air and water pump valves. Entire cab slides off for easy access to fittings. | |||

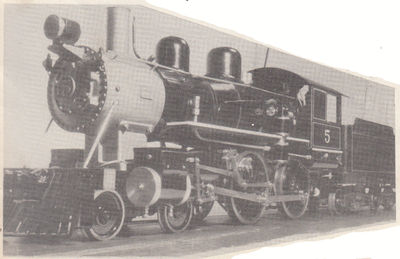

File:BillVanBrocklin Simplun 17 1956.jpg|The completed [[Simplun]], with headlight, pilot, tender, pumps and classification lamps. | |||

</gallery> | |||

Revision as of 12:27, 26 December 2015

A 4-4-0 Story in Pictures

Pine Street

Dover, Mass.

This 3-1/2 inch gauge engine was built with two objects in mind, one extreme simplicity and the other consistent reliability. After many tests in the last six months, these two objects were proved on the track. It is a free lance job, but in keeping with engines built around 1900-1920. One of the disadvantages of the eight-wheel types in smaller gauges is not enough weight on the drivers. In full size this is approximately 50% weight on drivers and 50% on pilot truck. In the little one this was greatly improved, the total engine weight being 40 pounds, of which 30 pounds are on the drivers. Side bar equalizing on the axle boxes and pilot touch frame side pivots make for good tractive effort, and on steel track tests with ball-bearing trolley she will pull 400 pounds, or 10 times her own weight without much effort. At one test on a 2% grade she hauled two adults up on 40 pound boiler pressure.

The engine is remarkably free from slipping with proper throttle starts and boiler capable of maintain all cylinder needs. Originally the boiler was built with eighteen 3/8 inch diameter and two 3/4 inch diameter tubes, and it was found the two bottom tubes frequently got blocked with cinders, so they were stopped up with brass plugs. This has made no difference to steaming and gave a better depth of fire, about 1-1/2 inch to top of grate.

The Walschaert valve gear gives good steam distribution and the best running position is two notches off center. It is of box link side pivot construction and as yet no signs of wear have been noticed. The reverse lever is unorthodox in that there is no latch. The lever carries a 1/8 inch ball and stiff compression spring behind it, the ball seating in indents in the quadrant. So far it has never loosened up and holds the gear in each position without shake.

A true hydrostatic lubricator was tried with cab feed control as an experiment and has worked very well, although oil feed adjustment is critical, but once correctly set, the engine can be run for hours with an almost dry stack. There is no lack of lubrication as slight weeps of oil can be seen at the steam chest joints. One thing has to be remembered and that is to shut off the steam supply when stopping for any great length of time. The cab sides and roof are connected in one piece with slides on front of each side. This allows it to be pulled up and off, no screws being necessary to hold in place. The cab deck and front remain on the engine. This has been a blessing for easier plumbing makeup and cleaning.

An injector sent by LBSC feeds to a backhead check which gives short steam and delivery pipes. It has performed consistently and after six months service hasn't been cleaned yet. Since most of the pictures were taken a small Westinghouse pump has been fitted. This is used as a water pump and has a single cylinder, 5/8 inch bore by 3/8 inch bore water and 1/2 inch stroke. It handles water feed just ticking over (after much trial and error!) A compressed air connection is in the steam line to run the pump when the engine is cold to fill the boiler. A similar connection is at the smokebox for blower. The blower is a single tube, 1/8 inch OD by 0.070 inch ID and is the best I have ever made, walking the "clock" up in no time at all. All in all, Simplum is one of my favorites, being very handy to carry around, especially when one has a flight of cellar stairs and three doorways to navigate through to get to the car!

Specifications

- Frames - 1/4 x 1-1/2 inch CRS

- Drivers - 4-1/4 inch diameter

- Pilot Wheels - 2-1/8 inch diameter

- Cylinders - 1-1/8 inch bore 1-1/2 inch stroke

- Cylinder Ports - 3/32 inch and 1/4 by 15/16 inch

- Tap - 3/32 inch, lead 1/64 inch

- Walschaert valve gear with floating hardened pins and eyes, all other motion plain bearing bronze bush.

- Axle-pump - 3/8 inch bore 1/2 inch stroke

- Hydrostatic lubricator, cab regulated

- Boiler - 3-3/4 inch OD at smokebox to 4 inch diameter at firebox, dummy lagged for extended wagon top looks

- Boiler tubes 2-3/4 inch superheater, 16-3/8 inch fire tubes all 9 inch long

- All boiler sheets 3/32 inch thick copper, girder stayed firebox

- Grate 2-1/4 inch by 5-3/4 inch, 1/8 inch square bars, 1/8 inch spaces

- Rotary throttle in steam dome 1/4 inch port, lever on backhead

- Engine weight empty - 40 pounds

- Tender weight empty - 14 pounds, holds 3 quarts water and 3 pounds coal

- Tender contains hand pump, suction control valve and injector valve

- Boiler pressure - 90 pounds

Photo Gallery

Shown in this photo is the firebox and flue assembly, already silver soldered ready for insertion into the outer shell. NOTE FIRST TIMERS: It will save you a little tussle if at this stage you will put the front tube sheet in position and silver solder, then slide the complete unit into the outer sheel. DON'T FORGET THE DRY PIPE!!!

The completed Simplun, with headlight, pilot, tender, pumps and classification lamps.