Robert C. Johnson: Difference between revisions

(Created page with "Category:People thumb|right|450px|Robert C. Johnson's English Switching Engine. <i>The North American Live Steamer</i>, Vol...") |

No edit summary |

||

| Line 3: | Line 3: | ||

<i>[[The North American Live Steamer]]</i>, Volume 1 Number 8 | <i>[[The North American Live Steamer]]</i>, Volume 1 Number 8 | ||

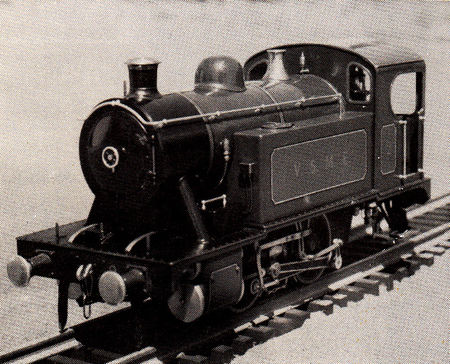

I'm enclosing a shot of my 0-4-0 English Switcher (free lance). I think she'll prove interesting to many of your readers, as basically she is [[Cliff Blackstaffe]]'s | I'm enclosing a shot of my 0-4-0 English Switcher (free lance). I think she'll prove interesting to many of your readers, as basically she is [[Cliff Blackstaffe]]'s "Beginner's Locomotive" with added frills. The only parts of her construction done out of my shop were the actual wheel castings and those for the cylinders. An attempt was made while making boiler fittings to really keep the size down as near to scale as possible, which greatly helps the appearance of the cab layout. I built my own pressure gauge and this has a case measuring 5/8 inch diameter by 3/8 inch in depth. Unlike the commercial efforts, the case has a prototype appearance. Some of her other features include working sanders, a variable stroke axle pump to feed the boiler from the side tanks and working cylinder drains operated from a disc valve located between the cylinders and controlled from the cab. | ||

The little oil boxes at the front ends of the tank lubricate the axle boxes while a conventional lubricator takes care of the cylinders. All four light | The little oil boxes at the front ends of the tank lubricate the axle boxes while a conventional lubricator takes care of the cylinders. All four light brackets on the front have an electric current in them with the intention of later building little lanterns for same. The cab also sports a gauge and water glass light fitted with a grain of wheat bulb. All rods and valve motion are made of dural with bronze and in some places hardened steel bushes to look after wear. By way of interest, I kept a record of the actual time involved in the construction of this engine and it works out to a total of 585 hours. | ||

: Robert C. Johnson | : Robert C. Johnson | ||

: 921 McKenzie Avenue | : 921 McKenzie Avenue | ||

: Victoria, B.C., Canada | : Victoria, B.C., Canada | ||

Latest revision as of 00:14, 6 February 2016

The North American Live Steamer, Volume 1 Number 8

I'm enclosing a shot of my 0-4-0 English Switcher (free lance). I think she'll prove interesting to many of your readers, as basically she is Cliff Blackstaffe's "Beginner's Locomotive" with added frills. The only parts of her construction done out of my shop were the actual wheel castings and those for the cylinders. An attempt was made while making boiler fittings to really keep the size down as near to scale as possible, which greatly helps the appearance of the cab layout. I built my own pressure gauge and this has a case measuring 5/8 inch diameter by 3/8 inch in depth. Unlike the commercial efforts, the case has a prototype appearance. Some of her other features include working sanders, a variable stroke axle pump to feed the boiler from the side tanks and working cylinder drains operated from a disc valve located between the cylinders and controlled from the cab.

The little oil boxes at the front ends of the tank lubricate the axle boxes while a conventional lubricator takes care of the cylinders. All four light brackets on the front have an electric current in them with the intention of later building little lanterns for same. The cab also sports a gauge and water glass light fitted with a grain of wheat bulb. All rods and valve motion are made of dural with bronze and in some places hardened steel bushes to look after wear. By way of interest, I kept a record of the actual time involved in the construction of this engine and it works out to a total of 585 hours.

- Robert C. Johnson

- 921 McKenzie Avenue

- Victoria, B.C., Canada