Martin Lewis: Difference between revisions

No edit summary |

|||

| Line 23: | Line 23: | ||

</gallery> | </gallery> | ||

== | == Marriage to Irene == | ||

By the early 1930’s Martin had moved from San Bernardino to Wilmington, California where he began working for Harpur’s Marine Engines. | By the early 1930’s Martin had moved from San Bernardino to Wilmington, California where he began working as a mechanical engineer for Chris Craft Boats and Chrysler Marine Engines, which later became Harpur’s Marine Engines. It was during this that Martin met [[Irene Lewis|Irene Ott]]. They were married on June 15, 1937, and moved to Wilmington. | ||

It was during this | |||

== Little Engines == | == Little Engines == | ||

Revision as of 21:08, 15 March 2016

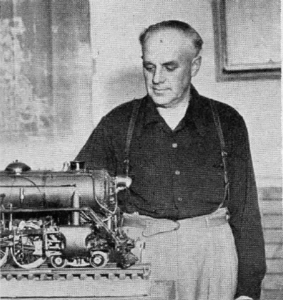

Martin Lewis was the founder of Little Engines.

Early Life

Martin Short Lewis, Jr. was born in Iowa on May 26, 1885. Early in life, Martin began a career as a mechanical engineer. He moved to Southern California in the early twentieth century and acquired a job working for J. Dale Gentry of Gentry Ford in San Bernardino, California.

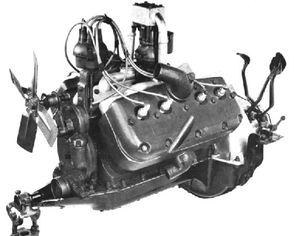

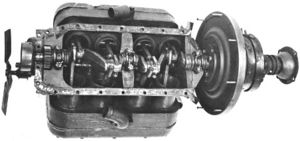

Gentry-Lewis V8

Ford Motor Company introduced a V8 engine for their 1932 Model B, quite an improvement over the four-cylinder engines common at the time. This is considered Henry Ford’s last major innovation, and it put his company ahead of the competition for the next 20 years. However, Gentry had the company beat by 15 years, for it was in 1917 that he and Martin Lewis, who was active in the automobile industry in Los Angeles, joined to produce their own V8 engine. They modified the Model T four-cylinder engine using parts manufactured and assembled in San Bernardino. The engine came to be know as the Gentry-Lewis V8.

The eight-cylinder block was fitted onto the Ford Model T engine crankcase, and used the same crankshaft, camshaft and carburetor. It could be installed in a matter of hours and converted the comparatively rough running four-cylinder motor into a powerful motor of smooth performance and high efficiency. And the cost? A mere $175.

Hanford Foundry cast the block, head and manifold, and Charles Linderoth’s Machine Works at Rialto and I Streets bored the cylinders. (The foundry is now gone. However, the machine shop building still exists, but most of its tools and other equipment have been removed and it is no longer an active business. Most recently it has been known as Toman’s Machine Works.) The engines were assembled by Gentry’s expert mechanics: W. E. (Slim) Vardy, John Wallace, Johnny Kennedy, and Walter Mapstead.

Twenty or thirty engines were built over a period of about one year. When Ford representatives heard about the Gentry-Lewis engine, they came to inspect it, and were not pleased. They told Gentry that their dealers must limit activities to selling their Fords, and that he must desist from further sales of his engine, which he did. Gentry kept his first engine in storage for about 40 years before loaning it to a Gentry Ford successor, Garner-Muth Ford. Garner put it on display for a while, but it eventually was sent to the Ford Museum in Michigan.

Marriage to Irene

By the early 1930’s Martin had moved from San Bernardino to Wilmington, California where he began working as a mechanical engineer for Chris Craft Boats and Chrysler Marine Engines, which later became Harpur’s Marine Engines. It was during this that Martin met Irene Ott. They were married on June 15, 1937, and moved to Wilmington.

Little Engines

From The Model Craftsman, August 1940:

Story of Lewis Little Engines

By Martin S. Lewis

The start of Little Engines dates back to April, 1934, when I wrote the series for The Model Craftsman on the construction of No. 7777, a 3/4 inch scale 4-6-4 type live steam locomotive. This series ran for 15 months, describing the construction of the locomotive, step by step, from making the patterns for the castings to painting the completed model.

In fact, the articles dealt with the project - from the rails up - in detail, but in such a way as to need as few machine tools as possible in a model of this sort.

Immediately upon publication of the first of the series, we commenced getting letters from persons who did not care to make the necessary patterns for themselves for one reason or another, but who did want the castings. So we arrange to provide the castings.

Then came the question of bolts and nuts in miniature sizes. Boiler and pipe fittings, and various other parts in scale, too, were apparently much in demand. And our reader-builders seemed at a loss for a source of supply for these needed parts.

We immediately went to work on the problem. Our first step was to obtain some of this material in the very quickest way possible - that way was by importation from European model factories. Then we started making them up ourselves.

Rail and fastenings were wanted more and more. We had an extrusion die made, from which duraluminum was extruded for us by the Aluminum Company of America. Then we had steel spikes and rail joints made. Tracking problems were further solved by our mahogany ties, the natural color of which resembled the creosoted ties of the big railway systems throughout America.

Having the various and many items in stock, it became necessary for us to get the articles and prices to our inquirers. This we did by publishing a 48-page catalog, showing castings, bolts, nuts, washers, metals - in fact, everything needed by the miniature live steam locomotive builders.

In this catalog, we provided our people with something much more than a mere list of supplies and materials. We included several pages of general information useful to the builders of working locomotive models of all types. This, we believe, has been sincerely appreciated.

As to our present line of engines, the latest is a 1/4 inch scale live steamer in two types - a 4-6-4 and a 4-8-4. We expect to bring out other models in the near future.

Previous to building No. 7777, I had built six locomotives, beginning with No. 1111. All but one were in 3/4 inch scale.

Our decision to build O-gauge live steamers is in answer to the many requests we've had from readers who want one or more such locomotives to augment the realism of their electrically operated roads. Because of technical problems, considerable research was necessary in order to work out good, reliable 1/4 inch scale steamers. We found that certain units which operated perfectly in the larger models were inadequate for 1/4 inch scale without changes in design.

These problems, naturally, required experimentation - and patience - to work out. But now we feel we have the problems in design and construction worked out, and we're ready to pass our findings on to our readers.

It is our future plan to make our instructions clearer, and to add more and more detail. We wish to be a help to those who want to build miniature locomotives, but who know prototypes only by sight and sound. Those who know locomotives thoroughly do not need our help.

We like to think that we are putting our drawings and instructions in such form that they will enable the builder to complete his task with a minimum of difficulty. We like for our builder to use his own discretion, and go as far as he likes, in adding detail. Yet, if he adds no detail to that shown in our instructions, he will still have a fine-appearing and operating engine.

In order to carry out our program, we feel that we need the help of our readers. So, we'll appreciate it if you'll just write to us in care of The Model Craftsman whenever you desire information.

Death

- Martin S. Lewis died May 30, 1949. His widow, Irene, carried on the business for about another 30 years.

References

- “They Tell Me”, Earl E. Buie, San Bernardino Evening Telegram, September 5, 1960

- "Who has a V8 in their T?"

- "SAN BERNARDINO: City home to first Ford V-8"

- "Martin and Irene Lewis, and Little Engines", Josh Knowles, Archive.org