Lathe Tool Setup: Difference between revisions

Jump to navigation

Jump to search

(Created page with "Category:Construction [[File:Lathe Tool Setup World Of Model Engineering No3.jpg|thumb|center|300px|From "The Lathe" by Stan Bray, "World of Model Engineering" No 3, 1989...") |

No edit summary |

||

| (7 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

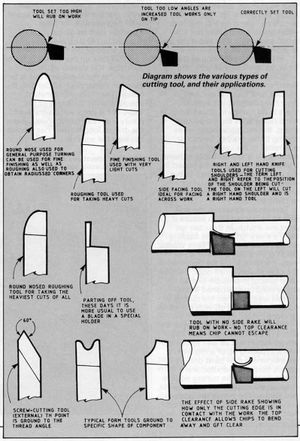

[[File:Lathe Tool Setup World Of Model Engineering No3.jpg|thumb|center|300px|From "The Lathe" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt1.pdf]] | [[File:Lathe Tool Setup World Of Model Engineering No3.jpg|thumb|center|300px|From "The Lathe" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt1.pdf]] | ||

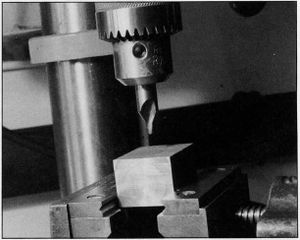

[[File:Drilling starts with center drill.jpg|thumb|center|300px|All drilling operations should start with a center drill; this gives an accurate and clean starting point, and reduces the chance of the drill bit "walking" off center.]] | |||

=== Centering Tip === | |||

A quick way to set the lathe cutter bit on center: | |||

Cut a strip of sheet metal about 1/2 inch wide and 6 or 8 inches long. Bring up the cutter with the cross feed to the work and then clamp the sheet metal strip gauge between the cutting edge of cutter and the work. If the cutter is on center, the gauge will lean toward you. If the cutter is above center, the gauge will lean away from you. | |||

This is real time save and quite accurate. | |||

: Gordon W. Corwin | |||

: 6986 Church Street | |||

: Highland, California | |||

[[File:GordonCorwin LatheCenterTip.jpg|thumb|center|300px|Gordon Corwin tip for centering lathe tool. From <i>[[The North American Live Steamer]]</i>, Volume 1 Number 6, 1956.]] | |||

== Drilling == | |||

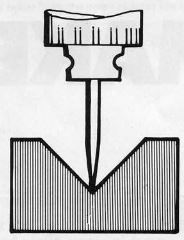

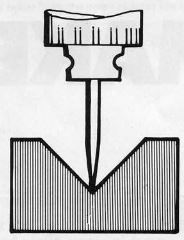

[[File:Drill Centering into vee block.jpg|thumb|center|300px|Before drilling round stock, hold a center in the chuck of your drill or mill and line it up with the center of a clamped vee block. From "Cross Drilling" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt3.pdf]] | |||

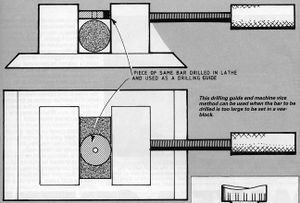

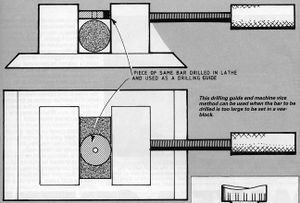

[[File:Drill Centering using same round stock.jpg|thumb|center|300px|Take a slice of metal of the same diameter as the work and center-drill it in the lathe. This can be put on top of the work in a machine vice and will act as a guide. This will also work for square stock. From "Cross Drilling" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt3.pdf]] | |||

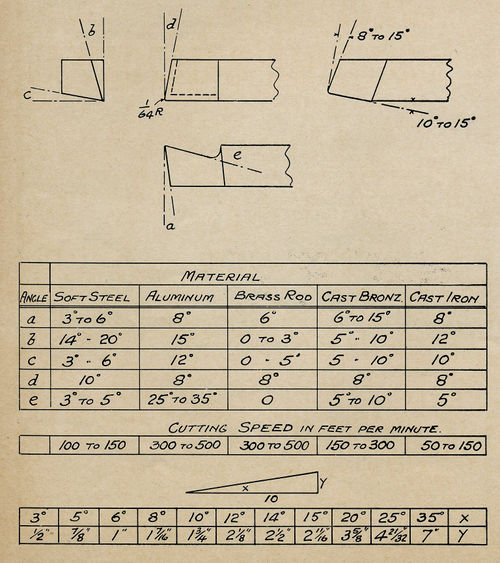

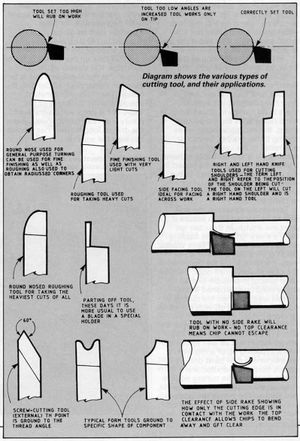

== Lathe Tool Angle Chart == | |||

See [[Cutting Angles of Tool Bits]]. | |||

[[File:LatheToolAngleChart HJCoventry 1953.jpg|thumb|center|500px|Lathe Tool Angle Chart by H.J. Coventry. From "The Miniature Locomotive", Nov-Dec 1953.]] | |||

Latest revision as of 22:38, 26 April 2015

From "The Lathe" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt1.pdf

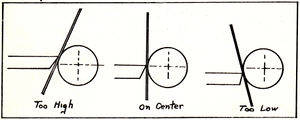

Centering Tip

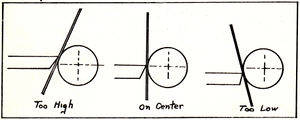

A quick way to set the lathe cutter bit on center:

Cut a strip of sheet metal about 1/2 inch wide and 6 or 8 inches long. Bring up the cutter with the cross feed to the work and then clamp the sheet metal strip gauge between the cutting edge of cutter and the work. If the cutter is on center, the gauge will lean toward you. If the cutter is above center, the gauge will lean away from you.

This is real time save and quite accurate.

- Gordon W. Corwin

- 6986 Church Street

- Highland, California

Gordon Corwin tip for centering lathe tool. From The North American Live Steamer, Volume 1 Number 6, 1956.

Drilling

Before drilling round stock, hold a center in the chuck of your drill or mill and line it up with the center of a clamped vee block. From "Cross Drilling" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt3.pdf

Take a slice of metal of the same diameter as the work and center-drill it in the lathe. This can be put on top of the work in a machine vice and will act as a guide. This will also work for square stock. From "Cross Drilling" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt3.pdf