Lathe Tool Setup: Difference between revisions

Jump to navigation

Jump to search

| Line 14: | Line 14: | ||

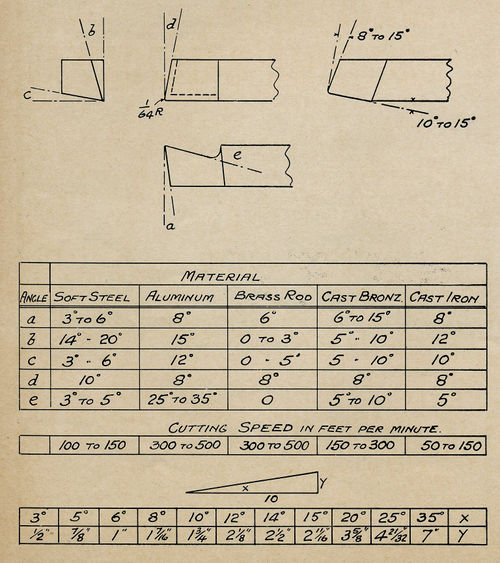

== Lathe Tool Angle Chart == | == Lathe Tool Angle Chart == | ||

See [[Cutting Angles of Tool Bits]]. | |||

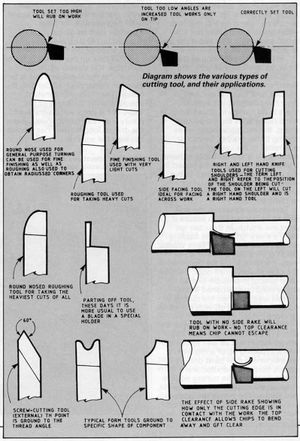

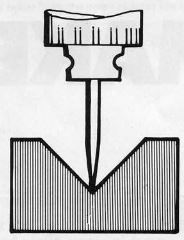

[[File:LatheToolAngleChart HJCoventry 1953.jpg|thumb|center|500px|Lathe Tool Angle Chart by H.J. Coventry. From "The Miniature Locomotive", Nov-Dec 1953.]] | [[File:LatheToolAngleChart HJCoventry 1953.jpg|thumb|center|500px|Lathe Tool Angle Chart by H.J. Coventry. From "The Miniature Locomotive", Nov-Dec 1953.]] | ||

Revision as of 22:27, 8 June 2014

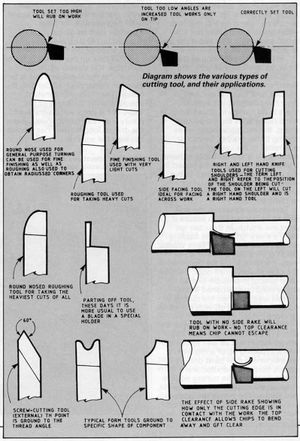

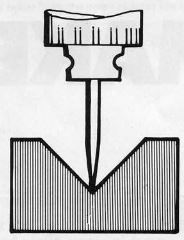

From "The Lathe" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt1.pdf

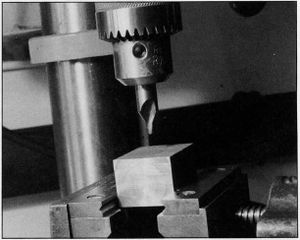

Drilling

Before drilling round stock, hold a center in the chuck of your drill or mill and line it up with the center of a clamped vee block. From "Cross Drilling" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt3.pdf

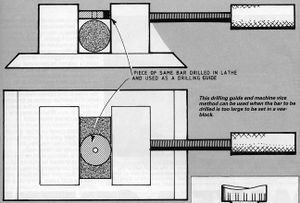

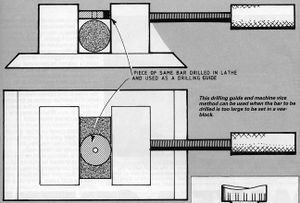

Take a slice of metal of the same diameter as the work and center-drill it in the lathe. This can be put on top of the work in a machine vice and will act as a guide. This will also work for square stock. From "Cross Drilling" by Stan Bray, "World of Model Engineering" No 3, 1989, http://www.model-engineer.co.uk/sites/7/documents/wome-3-pt3.pdf