LBSC's Virginia: Difference between revisions

| Line 30: | Line 30: | ||

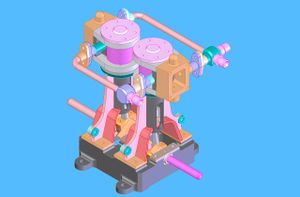

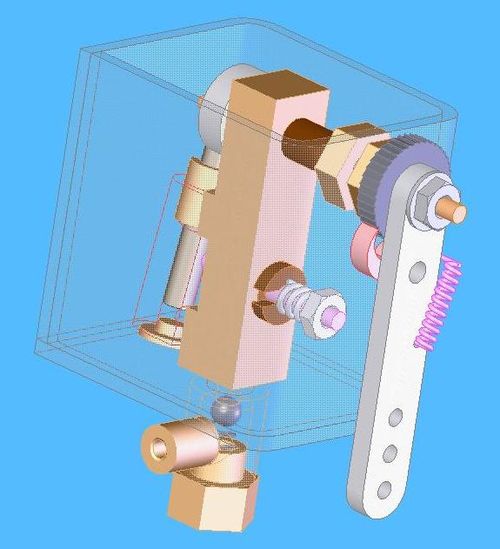

[[File:Don Althouse 040d.jpg|thumb|center|500px|Mechanical lubricator for LBSC's Virginia, modeled in SolidWorks by Don Althouse, 2014.]] | [[File:Don Althouse 040d.jpg|thumb|center|500px|Mechanical lubricator for LBSC's Virginia, modeled in SolidWorks by Don Althouse, 2014.]] | ||

My one concern about this endeavor is that my computer is very old as is my version of SolidWorks. I am running a 12 year old 32-bit Pentium 4 with an NVIDIA GeForce FX 5200 graphics card. Not the best system in the world for doing solid modeling. This will be by far the biggest and most complex model I have attempted to do on my system and I am not sure at this point if I will be able to get a full completed model due to lack of memory and the slow speed of my computer. | |||

SolidWorks is a memory hog and there in lies my concern, the more I get done, the more memory is used. There are different things I can try to accomplish the task but at this point I really don't know if they will work or not, we will just have to see. I believe I can get all the sub-assemblies done though. | |||

Revision as of 21:57, 27 April 2014

Modeling LBSC's Virginia in SolidWorks

by Don Althouse

April 14, 2014

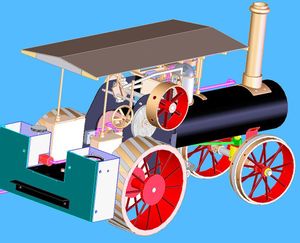

I have been attempting to make an electronic solid model of LBSC's Virginia from an article in Model Engineer written in 1956. This is by far one of the most complex and, shall I say, a bit hard to understand at times, projects I have found on the Internet to model.

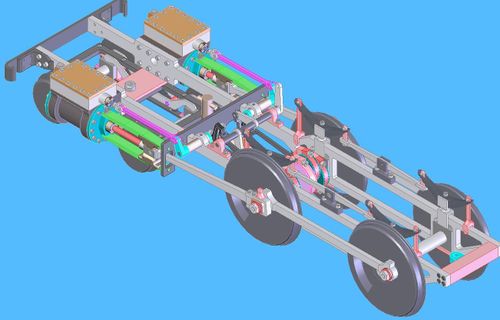

I am a mechanical designer engineer that loves to work with SolidWorks (my design program) and have been working on this model since about the middle of February 2014. I was starting to model the mechanical lubricator and in doing a little research ran across the IBLS website. I thought you might enjoy seeing what I have accomplished so far, so I am attaching a JPEG picture of what I call the chassis.

Now that I have read a little more in the article, it seems my frames will have to be updated once again to accommodate the lubricator mounts and the linkage, a never ending process but one I am quite use to as I have done my fair share of drafting and design work over the years. I hope you enjoy the picture, modeling this train has kept me quite busy and for that I am very thankful.

April 16, 2014

I have several other LBSC articles as well. The TichSm, Rose, Juliet, Dot and Doris Class 5, all of which I believe are original Model Engineer articles that I have downloaded from LBSC Steam Engine Plans.

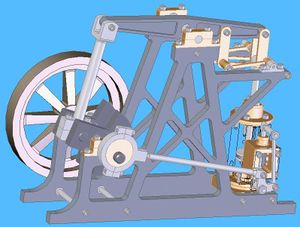

This website has been a great resource for me to get project plans to model and keep myself busy. I have modeled quite a few of the projects from this site, most of which dealt with steam, mainly different variations of steam engines, with the exception of an old CASE steam tractor model (see drawings below). I have been making these models for the past several years and was looking for something more involved when I ran across the LBSC article.

The more I get done with this LBSC model the more I am intrigued about Locomotives and the various ways they went about solving problems for various things. For instance the lubricator assembly, (not quite done and slightly modified, see attachment)what a great idea, so simple yet a very functional mechanical device, how cool!

My one concern about this endeavor is that my computer is very old as is my version of SolidWorks. I am running a 12 year old 32-bit Pentium 4 with an NVIDIA GeForce FX 5200 graphics card. Not the best system in the world for doing solid modeling. This will be by far the biggest and most complex model I have attempted to do on my system and I am not sure at this point if I will be able to get a full completed model due to lack of memory and the slow speed of my computer.

SolidWorks is a memory hog and there in lies my concern, the more I get done, the more memory is used. There are different things I can try to accomplish the task but at this point I really don't know if they will work or not, we will just have to see. I believe I can get all the sub-assemblies done though.