Emery Ohlenkamp

Emery Ohlenkamp, born 8 December 1908 and died 12 December 1999, is well known for his model live steam injectors.

Gallery

7.5 gauge 1.5 scale model of the 1897 Baldwin 4-4-0 American class Number 7 locomotive displayed at the Henry Ford museum. Scratch built by Master machinist and pattern maker Emery Ohlenkamp and completed in 1984. It has a dovetail copper boiler, coal fired, and the tender is brass. All the patterns and casting were produced by Emery along with two injectors he designed cast and machined.

History

- Emory worked for a mold shop and made tooling that no one else could do. Remember this was before the days of CNC machines. I think his first injector was for a three inch scale Case tractor that he built. I saw the tractor years ago when I visited Em. The tractor was phenomenal.

- Em apparently made all the turned parts on a 9" South Bend lathe. If I remember correctly the lathe was improved by a piece of steel several inches thick under the lathe bed. I also remember that he cast his own injector bodies, no commercial foundry could do them to his satisfaction. I have seen two different types of his cast injector bodies, I do not know if he cast both types.

- Howard is correct about Em. Em was my mentor and was an incredible machinist. We called him the Mozart of the Bridgeport.

- He had 2 South Bend 9 inch lathes, one set up just for cones and close fits. It was absolutely the smoothest South Bend I have ever seen and the lathe was bolted to a 800 pound plate of steel...just one of Em's tricks to get the best possible turning work.

- All his injectors worked, or did not leave his shop. He had a 3 foot tall steam boiler and a test bed set up, and each injector was run through it's paces for pressure and volume, before shipping.

- He had two bodies after he found someone was replicating his injector when he received a few that didn't work. Fellows thought they were Em's and returned them for repair. Probably made in China and this was in the early 70's. He did not appreciate this, and then put a serial number on each one with his emblem 'EM'.

- He knew a lot about brass and bronzes, and if you use the wrong one, you get shorter life as certain water minerals can etch the material. Em used manganese bronze for his bodies and many parts.

- I helped him cast the bodies a few times. We did it in his garage. He used shell molds baked in his kitchen oven, and we poured about 20 at a shot, maybe 5 times in a short evening. I last helped Em pour injectors in about 1988 as I recall, and it was the last batch. He sold them into the early 90's, and passed away in 1999. Most all of the molds/fixtures were destroyed after he died.

- I helped Emery Ohlenkamp cast the last few hundred of his injectors and thought I should comment. Em did not use wax, but did sand molding. The molds were made with permanent steel patterns and a thermo-set "fine" sand mix. The molds and cores were baked and then assembled individually - the alignment bosses were so accurate. The finished bodies look like they were wax cast.

- Em used Manganese Bronze and it came in virgin ingots and yes, he was careful to use flux/degasser before we poured the melt. The metal was very pure, but you still pick up dirt/oils in handling, as well as oxygen and moisture. We did about 40 to 60 bodies at a time.

- Not only were the bodies inspected, but Em assembled and checked every new injector with steam and water to ensure output requirements were met. Then they were cleaned and packed.

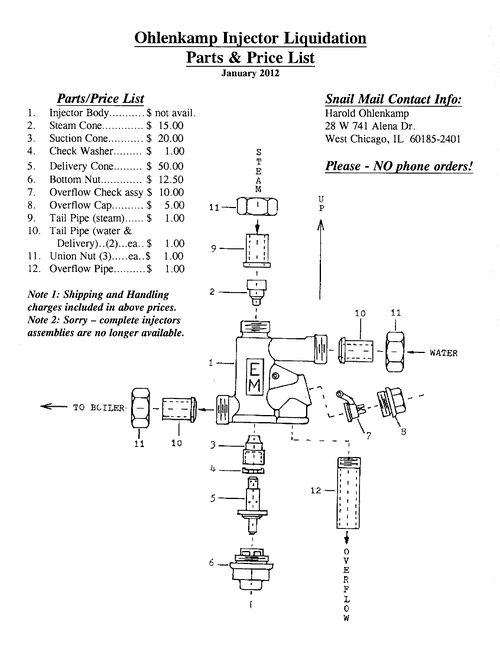

- Harold Ohlenkamp (Emery O's son) is selling spare parts for Ohlenkamp injectors. Please note...complete injectors are NO longer available. However, there is still a supply of fittings, cones, etc. A parts identification price sheet and injector installation instruction sheet are attached for reference. When the parts are gone...they are gone forever. It was Emery's wish that any and all associated tooling be destroyed after his passing. Harold is simply selling off the remaining parts and pieces he has in stock. At some point, remaining inventory will be discarded.

- Live steamers are welcome to contact Harold (snail mail ONLY). Harold would prefer this method of contact since his wife is not in the best of health and Harold wants to be sure any messages/orders are not lost. If you provide a phone or email address, he may contact you directly. Harold's mailing address is listed on the price sheet.

The following Want Ad appeared in Popular Aviation, June 1933:

- Heath Parasol Wings, fuselage and tail unit. New, excellent workmanship. Will exchange for a screw cutting lathe in good condition. - Emery Ohlenkamp, R.F.D. 1, Box 51, Grant Park, Ill.

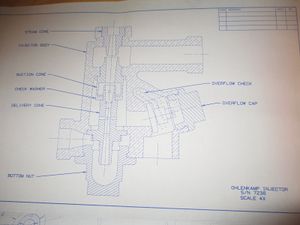

Ohlenkamp Injector Installation

Posted by Carl B. on Chaski.org:

Injector must be mounted in a vertical position. The steam pipe should be on an independent line and connected to the boiler at the highest and closest possible point. A ball valve that opens full flow in 1/4 turn in ideal as a steam supply valve. 5/16 inch outside diameter tubing is a good size for all piping to the injector and also as a delivery line.

The water supply line should have a good capacity, fine mesh strainer and a shut off valve to regulate the water supply.

The injector should be mounted low so that the water will flow by gravity to it from the tender. This will cool the injector in case it gets hot and refuses to pick up. The injector is designed to lift but reliability is lost for the above reason if it is mounted high.

The delivery line should be direct and straight with as few elbows as possible. There should be at least one check valve in this line as well as a shut off valve. The shut off valve should be between the check valve and boiler so that the check valve can be serviced in case of sticking or leakage. A leaking check valve will blow back and overheat the injector causing it to not pick up.

The tail pipes are tapped 5/16 inch 27 threads-per-inch tapered thread. These pipes can be bored out for 5/16 inch diameter to slip into for about 1/2 inch and then the joint silver brazed.

DO NOT LOSE THE STEAM CONE. It may fall out when the union nut is unscrewed from the top of the injector. Note that the tail pipe seats on the steam cone and has a flat face instead of a radius as the other 2 have. The suction and delivery pipes have a radius to match the seat in the body.

It is important that the water supply connections as well as the valve stem packing do not leak air. Any air leakage will cause the injector to quit.

Capacity will vary with different conditions but is about 2 quarts per minute at 125 P.S.I.

After a time the cones will be coated with lime and minerals from the water supply and need to be removed and cleaned in vinegar or acetic acid solution. The steam cone is tapped 10-32 and can be removed by pulling it out with that size screw.

The next step is to unscrew the 7/16 inch square nut on the bottom and the delivery cone will come out with it. Take care not to loose the 11/32 inch diameter washer that is on this cone. This washer should be a free sliding fit on the cone. It has a tendency to lime up and stick solid. Note that it has a raised lip or seat on one side and this should face up towards the suction cone above it. Do not use tools on this washer to free it as you will damage it. Use fingers only along with the vinegar treatment.

To separate the delivery cone from the nut proceed as follows: Grasp the nut with thumb and fingers of one hand and the cone the same way with the other hand and with a pulling and slightly wiggling or back-and-forth bending motion the 2 parts will separate. Now you can look through the cone to look for blockage and also the acid can get to all of the parts. Use a wooden tooth pick to help a bit. Do not use metal inside the cones.

The suction cone is a press fit in the body and is best not removed or it may be damaged and a new one needed.

Do NOT LEAVE IN THE ACID MORE THAN A COUPLE OF HOURS. The acide will attack the cones after the line is gone and ruin them. The acid will act much faster if it is heated.

Be very careful not to drop the cones on a hard surface or the edges will be damaged.

Below about 100 P.S.I. the water feed needs to be gradually restricted as the pressure drops or water will dribble or run from the overflow.

Obituary

December 14, 1999

Emery William Ohlenkamp, 91, of Wheaton and formerly a longtime resident of Chicago, died Sunday, Dec. 12, in Central DuPage Hospital in Winfield. Born in Beecher, Mr. Ohlenkamp was a retired pattern maker for Chicago Magnesium Castings. Survivors include his wife, Ruby E.; a son, Harold; four grandchildren; and four great-grandchildren. Services will be at 11 a.m. Wednesday in Fullers Cemetery in West Creek Township, Ind.

Tribute

On Sunday, December 12, 1999, Emery Ohlenkamp quietly passed away in Wheaton, Illinois. His 91st birthday was only 3 days earlier. Creator and builder of the Ohlenkamp Steam Injector, Emery set the highest standard for all miniature steam injectors in performance and dependability. A wizard at machining "Em" (as he was affectionately known) could consistently hold tenths on the 2 Southbend Lathes while making cones and parts for his precision injectors.

Em was very proud of every one he made. Even though production ceased in 1980 so Em could do the other things that were important to him, His Injectors are still a treasure to have on a live steam locomotive. A mark of the man and his capabilities!

Some of the intricate manual work Em did on his Bridgeport defies explanation, unless you consider 4 axis CNC as an alternative. Em retired in the 1970's from Chicago Magnesium where he was employed as a Master Pattern Maker, and also worked for Universal Castings prior to that.

During the depression He applied for a job with many, many other applicants. When asked what made him qualified to assume the position, Emery took an immaculate scale Corliss governor out of his pocket that he scratch built and he was promptly hired on the spot!

During the 1940's, Em and Walter Johnston built one of the earliest 7-1/2 inch tracks in the Illinois/Indiana area. Summer days would find him along with other members of the Chicago Model Engineers running his 1910 style American on the 1/2 mile track. For kicks, Emery would also bring out his Case traction engine, either the full size one, or his incredible model version in 3 inch scale. The only purchased part on it was the pressure gauge. Emery even made and roll formed the rivets so that they and everything else exactly matched every detail of the full size one!

As an active member of the CME, he always had interesting projects to show. His love and knowledge of steam was displayed in a simple "Aerosol Can Steam Engine" to Boiler nights when his stationary boiler was set up and used at his shop to power other members engines.

His soft spoken voice, vast mechanical knowledge and friendly nature will be missed by his many friends here and abroad.