Boiler backhead: Difference between revisions

| Line 21: | Line 21: | ||

File:Firedoor ring mounting Charles Pipes.jpg|This fire door frame was fitted with 5-40 countersunk machine screws. Photo by Charlie Pipes. | File:Firedoor ring mounting Charles Pipes.jpg|This fire door frame was fitted with 5-40 countersunk machine screws. Photo by Charlie Pipes. | ||

File:Challenger Backhead Dietel.jpg|Backhead for a 1 inch scale UP Challenger (oil fired). | File:Challenger Backhead Dietel.jpg|Backhead for a 1 inch scale UP Challenger (oil fired). | ||

File:Oil Burning Pacific Backhead Vance Nickerson.jpg|Backhead view of a 1.5 inch scale Pacific. I install dry pipes on my boilers whether coal or oil firing for the turret to help with the atomizer getting as dry steam as possible. Never attach the sight glass to the turret. I'm not hesitant to drill and tap the boiler shell but I always use heavy wall tubing. Photo and text by Vance Nickerson. | |||

</gallery> | </gallery> | ||

Revision as of 14:37, 8 March 2022

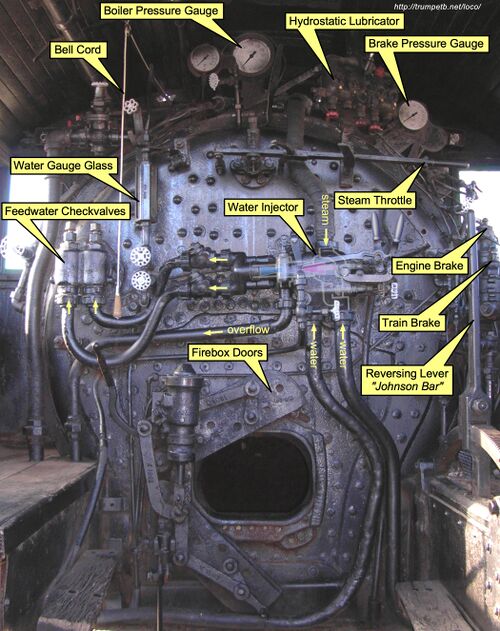

The backhead of a steam locomotive is the end of its firebox facing inside the cab. Most of the locomotive’s controls used by the locomotive’s engineer and fireman are mounted on the backhead. All the controls needed to manage the firebox’s fuel intake, boiler’s steam pressure, the locomotive’s speed and direction, and a whole lot more are within easy reach of its crew.

Backhead Components

Gallery

Shay backhead showing the syphon protecting the pressure gauge.

Backhead view of a 1.5 inch scale Pacific. I install dry pipes on my boilers whether coal or oil firing for the turret to help with the atomizer getting as dry steam as possible. Never attach the sight glass to the turret. I'm not hesitant to drill and tap the boiler shell but I always use heavy wall tubing. Photo and text by Vance Nickerson.