Turnouts

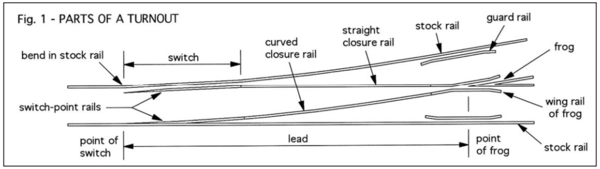

A railroad switch, turnout or [set of] points is a mechanical installation enabling railway trains to be guided from one track to another, such as at a railway junction or where a spur or siding branches off.

The switch consists of the pair of linked tapering rails, known as points (switch rails or point blades), lying between the diverging outer rails (the stock rails). These points can be moved laterally into one of two positions to direct a train coming from the narrow end toward the straight path or the diverging path. A train moving from the narrow end toward the point blades (i.e. it will be directed to one of the two paths depending on the position of the points) is said to be executing a facing-point movement.

Unless the switch is locked, a train coming from either of the converging directs will pass through the points onto the narrow end, regardless of the position of the points, as the vehicle's wheels will force the points to move. Passage through a switch in this direction is known as a trailing-point movement.

A switch generally has a straight "through" track (such as the main-line) and a diverging route. The handedness of the installation is described by the side that the diverging track leaves. Right-hand switches have a diverging path to the right of the straight track, when coming from the narrow end, and a left-handed switch has the diverging track leaving to the opposite side.

A straight track is not always present; for example, both tracks may curve, one to the left and one to the right (such as for a wye switch), or both tracks may curve, with differing radii, while still in the same direction.

Size

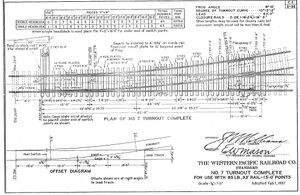

The size of the turnout is indicated by its "Number", such as a No. 7, shown below.

Components

Frog

Points

In most cases a recess must be cut into the main rails to allow a smooth transition into the beginning of the points.

Carl from Midwest Scale Rail, LLC wrote:

- I taper the base of the rail, and notch the head as well, about 5.25 inches long. I use my vertical/horizontal band saw and roller stand from harbor freight. I use a square to mark the angle on the base, then cut it alone the scribed line. I use an angle grinder to notch the head of the rail, and smooth out the angle on the base.

Guard Rail

The purpose of the four wheel guards in a turnout is to maximize the amount of tread on the frog while assuring the flange does not touch the frog.

Springs

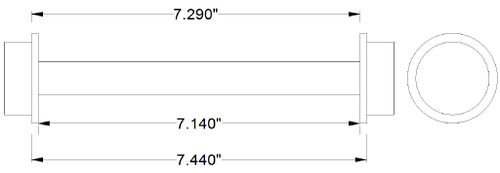

Ken Smith, renowned track building in Texas, recommends using the following springs from Lee Spring Company.

- Stock Code: LC 038E 18 M (CAD drawings available here)

- Outside Diameter (inch): 0.36

- Hole Diameter (inch): 0.375

- Rod Diameter (inch): 0.271 (Fits over 1/4 inch threaded rod)

- Free Length (inch): 2.5

- Rate (lb/inch): 5.8

- Solid Height (inch): 0.714

- Wire Diameter (inch): 0.038

- Material: Music Wire

- Load at Solid Height(lb): 10.3

Ken has installed these springs on many turnouts on the Comanche & Indian Gap Railroad and others. He said to adjust the tightness of the springs on the rod so that a truck can be run through against the switch to open the spring points without derailing.

Ron Kunst wrote September 19, 2014:

- Eureka, by Jove I think we got it mates!!!! I think I have finally found the right springs, after about 7 or 8 try's. This is with a set of Century Springs #C-690. 2 1/4" free length, 7/16" OD, .056 Dia wire, .625 bottomed length and 7.75 lbs full load. The bench tests are done, now to install the switch and start the field testing. I also have another switch that is out by the garden to put these springs into and another left hand switch to put them on. Fun, Fun, Fun.....

<videoflash>ZtHqgmfqo2s</videoflash>

Kick Switches

Rick White wrote on Discover Live Steam Yahoo group:

- One type of kick switch at Jack Haskins's Able Springs & North Texas Railroad. These work well by foot, and he has dozens. The car wheels will also move them over when you trail through a switch that is not set for your direction of movement.

George Erhart posted photos of the Colorado Live Steamers kick switches on Discover Live Steam Yahoo group.

Notched Continuous Rail

Bill Koster wrote:

- I did a couple of switches, using a notched continuous rail. This makes a very smooth running switch, since the joints are eliminated.

Switches using a notched continuous rail. Photo by Bill Koster.

Here is a close up of a switch frog that I made. While it may not be the prettiest one I have made, it worked well. You will notice how I notched the rail, carefully, with a Skill saw! Photo by Bill Koster.

Switch Stands

Railroad Supply Corporation's cast bronze switch stand in 1.5 inch scale.

Hockey Puck

See Hockey puck.

Expert Advice

Bill Koster wrote on Yahoo LiveDiesel:

- If you hold the gauge to 7 1/2 inch (or 7 1/4 inch) at the points, the points should not have to travel more than 3/8 inch. Make the points as easy as possible to move. Bill Hays suggests using the "Goldsby bump", putting a slight downward bend to the points so they just barely clear the ties, only touching at the ends of the points. I don't have a number or size of the spring I have used handy but it is about 5/8 inch diameter and a couple inches long. When I didn't have a spring handy I even used a bungee cord as a spring.

- You can use angle iron for the points, but the head of the rail is then quite narrow, unless if you use something like 1/4" x 1" x 1" angle iron. Channel iron makes prototype looking switch points. Yes, you can do it many other ways but stop and think, do we want our track to look like the full sized?

Bruce Mowbray wrote on Yahoo LiveDiesel:

- I would like to add that you don't need much pressure. Only the amount that will pull the points back against the rail. Too much pressure and unloaded cars will tend to climb up the back side of the point and derail. I did some trial and error experimentation with some air powered switches and found that more than 5 pounds of air in a 3/4 inch bore cylinder caused these type of derailments with light weight cars. It only took 2 or 3 pounds to pull the points in tight, depending on how clean the stainless steel point slide plates were. Dirty and wet took more pressure to move the points.

Jay wrote on Yahoo LiveDiesel, Sept 2014:

- I use the following springs from McMaster-Carr:

- Item: 9657K158 (Steel Compression Spring 2.5" L,.438" OD, .048" Wire, Packs of 12, $9.52)

- I have used these springs with great success on all my switches.

External Links

- "Turnout", Robert W. Maynard, Live Steam, April 1972

- "Building a Switch Stand", Alfred W. Frese, Live Steam, May 1972

- "Turnout Design and Fabrication Part 1: Design and Layout" I. Douglas Alkire, Live Steam, September 1974

- "Turnout Design and Fabrication Part 2: Fabrication" I. Douglas Alkire, Live Steam, October 1974

- "Turnout Design and Fabrication Part 3: Frog Assembly Drawings" I. Douglas Alkire, Live Steam, November 1974

- "Turnout Design and Fabrication Part 4" I. Douglas Alkire, Live Steam, December 1974

- "Turnout Design and Fabrication Part 5: Switch Points" I. Douglas Alkire, Live Steam, January 1975

- "Turnout Design and Fabrication Part 6: Switch Points" I. Douglas Alkire, Live Steam, February 1975

- "Turnout Design Consideration: In Depth Look", I. Douglas Alkire, Live Steam, April 1982

- "Permanent Way: 3-way Stub Switch", Tom Stamp, Live Steam, November/December 1996

- "How I Built a Bryant 7.5 inch Gauge Turnout", Douglas Wan Veelen, Live Steam, July/August 2005

- "Power-Actuated Kick Switch", Ron Trenhaile, Live Steam, January/February 2007

- See also Live Steam, July/August 2001

- "Park Gauge for the Beginner on a Limited Budget: Building Switch Stands", Malcolm Mackey, Live Steam, January/February 1999

- "New Switch Stand", Scott Pointon, Live Steam, March/April 2000

- "Track Accessories: Switch Machine, Bench, Fuel Tank", Dan Foltz, Live Steam, September/October 2005

- "Special Switches Solve Layout Problems", Steve Booth, Live Steam, July/August 2006

- "Turnout Construction", Carl Baskin, DiscoverLiveSteam.com

- "Switch Building at Maricopa Live Steamers", DiscoverLiveSteam.com

- "Backyard Railroad Standards", Chaski.org

- "Switch frog info", Chaski.org

- "Three Way Switch", Kap Pullen, Chesapeake & Allegheny Live Steamers

- "More on Frogs", Chaski.org

- "Turnouts...What You Need to Know", Pacific Coast Region NMRA

- "Railroad switch", Wikipedia

- Train Mountain Switch Stand Installation 2015 (PDF)

- "Railroad Supply Corp Switch Stand Castings", Chaski.org

- "Switch Stand Tutorial", Train Mountain, PDF

- "Illustrated Guide for Building a Switch (Turnout)"

- "Kick-Switches", Chaski.org

- "Make a Set of Switch Points from Angle Iron for $10", Chaski.org

- "Switch Point Derailments: Is it the point or the wheel?", Interface

- "Calculating Tie Length in a Switch", Island Pond RR

- "Please Post Your Thoughts", Chaski.org, Contains photos and info on turnouts

- "Switch construction rail lengths", Chaski.org

- "7.x gauge 3-way switch", Chaski.org