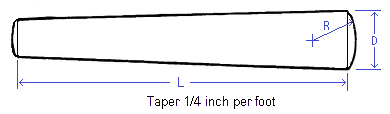

Taper pin

A tapered pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized tapered pins have a taper on diameter of 1:48 while metric ones have a taper of 1:50. A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1/4-inch taper over a 1-foot length.

Taper pins self lock. As they are seated a friction force develops along the whole length and diameter of the pin which locks the pin in place.

The diameter at the small end of ASME Taper Pins is a function of the length (i.e. the large end in any size remains the same and extra length is added to the smaller end). Therefore the small end should be specified as a reference dimension for determining drilled hole size. It shall be computed by multiplying the nominal length of pin by the factor 0.2083 and subtracting the result form the basic pin diameter.

| No. of Taper Pin | Diameter Large End D | Approx. Size D | 1st Drill thru size | Second Drill | |

|---|---|---|---|---|---|

| Size | Depth | ||||

| #7/0 | 0.0625 | 1/16 | 0.0469 | ||

| #6/0 | 0.078 | 5/64 | 0.0469 | ||

| #5/0 | 0.094 | 3/32 | 0.0625 | ||

| #4/0 | 0.109 | 8/64 | 0.0781 | ||

| #3/0 | 0.125 | 1/8 | 0.0938 | ||

| #2/0 | 0.141 | 9/64 | 0.0938 | 0.1094 | 1-1/4 |

| #0 | 0.156 | 5/32 | 0.0938 | 0.1250 | 1-1/2 |

| #1 | 0.172 | 11/64 | 0.1094 | 0.1406 | 1-1/2 |

| #2 | 0.193 | 3/16 | 0.1094 | 0.1406 | 1-3/4 |

| #3 | 0.219 | 7/32 | 0.1406 | 0.1719 | 1-3/4 |

| #4 | 0.250 | 1/4 | 0.1719 | 0.2031 | 1-3/4 |

Reamer

The taper pin hole is drilled to the size of the small end of the taper through both the collar and the axle. Longer pins may required step-drilling part through the hole (see table above). The hole is completed using a taper pin reamer of the same same.

From Smokstak:

- The taper pins are all the same taper, they are just sliced out at different diameters and lengths. You'll need to measure one of the holes, the big hole or the small hole. Compare that to the chart above to get the pin and reamer you need.

- You can ream the hole with the tapered reamer. If you keep reaming it will go deeper and deeper making the hole bigger and bigger. The more you ream the deeper the pin will sit into the hole. Ream only what you need to get a clean hole (no cylindrical areas from the drilling process). Tap the new pin in slightly until it has a snug fit. The pin should be exposed on both ends. If not you may need to use the next larger size. They make pins of different lengths so you can get what you need.

- If there is enough of the pin exposed on both ends then give it a couple more taps to seat it in another 0.005 mils or so. Don't hammer the pin in too hard as the pin will never come out easily and you could overstress the part. Grind or cut off the excess parts of the pin. Make the ends pretty. I like to leave a little bit of the small end exposed (about 1/8") and then use a sharp prick punch and punch two dimples 180 degrees apart. That way the pin won't come out even if it loosens up but you can grind it off and then drive the pin out when you want to take things apart.

- Get a GOOD set of reamers or a couple of the size you need, it will be worth it. Use lots of cutting fluid, and don't ream too quickly or push too hard. The shop should drill a hole close enough to the size so the reamer will find the center. I use a Milwaukee hole shooter and never go very fast, maybe a quarter of the top speed. Go lightly and use lots of fluid on your first time. Once the reamer stops reaming and is dull get another reamer. On the extreme case, if you keep running the reamer without cutting you could work harden the material.

Application

- When I worked for IBM we still had card machines when I started that used taper pins all over the place. We were issued an assortment of taper pins about 3 inches long in different sizes. The standard procedure was to put a new pin in the hole and ream the hole if necessary. The new pin was marked on each end, then nick the pin with a file just outside the gear or pulley, break off the unneeded ends, dress the ends with a file and drive it home.

From CNCZone.com:

- Taper pins may be used for planar part alignment. Dowels will not give you the precise registration that taper pins will give you. The use case is a bit different though. With taper pins, you do all of your alignment, then you drill and ream for your pins. This way if you ever have to take things apart, you can re-establish the original orientation. You can't do that with dowels since dowels either require clearance or will cause wear upon removal. Taper pins are zero clearance. If there is any wear when they are removed, they can be put back in a bit deeper and they will snug up. They are also easy to work with if things shift a bit after an overhaul. Simply ream clean again.