Live Steam in 1/240th Scale: Difference between revisions

| Line 106: | Line 106: | ||

Now, as all users of small jets know, blockages will occur, so a pricker is required. Pricking from the outside of the jet was obviously a very delicate operation, and it doesn't sound very sensible to push the muck back into the larger end of the hole. The best solution seemed to be to unscrew the whole burner, jet and all, and introduce the pricker from the back it's easier to get it started in the no. 80 hole. The first pricker was a long coned point ground on a needle, but this stuck in the jet and the tip snapped off and stayed there. So now I use a piece of piano wire with a log coned point; it's hard enough to do the job but not so brittle as the needle. Since the jet hole is several diameters long, there is little danger of increasing its size when using the pricker; a short jet hole is easier to make, but also very much easier to enlarge when pricking. During this operation, I use a 10 magnification eyepiece to see the tip of the pricker emerge from the small end of the jet. | Now, as all users of small jets know, blockages will occur, so a pricker is required. Pricking from the outside of the jet was obviously a very delicate operation, and it doesn't sound very sensible to push the muck back into the larger end of the hole. The best solution seemed to be to unscrew the whole burner, jet and all, and introduce the pricker from the back it's easier to get it started in the no. 80 hole. The first pricker was a long coned point ground on a needle, but this stuck in the jet and the tip snapped off and stayed there. So now I use a piece of piano wire with a log coned point; it's hard enough to do the job but not so brittle as the needle. Since the jet hole is several diameters long, there is little danger of increasing its size when using the pricker; a short jet hole is easier to make, but also very much easier to enlarge when pricking. During this operation, I use a 10 magnification eyepiece to see the tip of the pricker emerge from the small end of the jet. | ||

== The D. & H. 4-8-0 == | |||

In this model, the first of the trio, the ports in the valve sleeve are drilled 0.02 inch diameter the piston valve having a diameter of 0.05 inch and 0.05 inch travel. On testing the valve timing on compressed air and making the final adjustment by pressing the valve sleeves a few "thou" either way axially in the cylinder block (not the best traditions in engineering, I admit) the best compromise i could get wasn't very good. Still, the chassis buzzed round merrily on less than 10 p.s.i. so I let well alone. The front cylinder covers are of very uncommon design in this model; the usual ring of studs holding the lid on is just not "on" in this scale. Also, as the cylinder block stretches right across the loco, the main frames couldn't pass through from back to front, so there was nothing to hold up the front pilot beam! One doesn't worry much about such trivialities when getting a new design to work for the first time. The pilot beam isn't functional, but the cylinder covers are. Why not make the pilot beam support and both cylinder cover in one piece? This idea solved both problems, as I managed to find room for four bolts to hold it on somewhere between the cylinders and valve chests that showed their (erstwhile) open ends on the front face of the cylinder block. The steam connection to the cylinder block is via the banjo union on the left side of the model just above the crosshead; this is visible in the photograph showing the state of progress just after the first run on the track. | |||

[[File:AASherwood DH 2 8 0.jpg|thumb|center|500px|D&H 2-8-0]] | |||

== The GN 2-8-2 == | |||

This model was started after the D & H 4-8-0 had been completed with enough frills to make it look like a loco - or perhaps I should say like the prototype, as there are probably many of the loco fraternity who would deny that the prototype ever looked like a locomotive. The G.N. 2-8-2 was the biggest Mikado ever made; the loading gauge on this railway is very high and wide and that means handsome when working in small scale. The overhang behind the rear coupled axle is so long you wouldnot believe it without proof. It's more than many locos with 4 wheel trailing trucks had. In fact the overall suitability seemed so good that I freely forgave the designer for putting Walschaerts valve gear on it, and got down to the task of designing a linkage that would work in this scale and deceive all but the most critical of observers. | |||

There are so many joints in linkage where lost motion can occur that the aim of the design is to minimise the number of joints. The first idea was to drive the valve by one link from the return crank to the valve direct. It might be possible to bend this link in a cunning manner behind the expansion link, but on investigation this couldn't be made to look realistic even to [https://en.wikipedia.org/wiki/Mr._Magoo Mr Magoo]. Adding two more joints solves the problem however; the gear is conventional from return crank to expansion link, and the radius rod pivots from a point fixed in the expansion link direct to the valve. The union link and combination lever are frills added later, are not functional. The phasing of the return crank can be set to give any cut-off desired and the main length of the radius rod doesn't have to go direct from pivot to pivot; it can take any course we like to deceive the observer that he is looking at the real thing in motion. I began to get very enthusiastic about the whole sneaky business! Just as well perhaps, as I found enthusiasm very important when I got down to detail design. | |||

[[File:AASherwood Figure5.gif|thumb|right|300px|Figure 5]] | |||

The outside faces of the drivers take up a width of 0.31 inches. The loading gauge is 0.55 inches wide. Within the space of 0.2 inches on each side one has to get in the connecting rod, coupling rod return crank, eccentric rod and the nut to keep the latter from coming off. That means an average thickness of 0.024 inches per item - or less if some clearance is deemed desirable. How does one make a return crank so thin with positive location? Make it in one piece with the crankpin and pressfit to the wheel, remembering to put the coupling and connecting rods on first! O.K. if you are so sure that you don't want to take it apart again - and I usually find I have to. My final solution is shown in the exploded sketch (Fig. 4). The crankpin is 0.06 inch diameter and the c/sk head screw that secures the return crank is threaded 0.032 inch diameter. I apologize for the horrible sight of the screwdriver slot, but since the screwhead cannot be allowed to protrude from the return crank no other solution seems possible. The crankpin is, of course press fitted to the driving wheel. | |||

Remembering the poor valve events on the 4-8-0, due to the wayward tendencies of small drills, I cut the ports in the valve liners with a 0.01 inch thick saw cutter. Not the usual commercial article, which in this thickness wanders as badly as small drills. I used a home made one like a small woodruff cutter with integral shank 1/8 inch diameter, the cutter being 3/16 inch diameter silver steel, hardened and tempered, random spaced teeth, no top rake, side or front clearance - all against the book - and the result was ports to within 0.0061 inch precision in spacing and width. | |||

The final adjustment to the valve setting is by screwing the crosshead in or out. There is no room for a locknut here, but the threads are tight enough to stay put - if they weren't, a small smear of [https://en.wikipedia.org/wiki/Araldite Araldite], or even paint would do the job. Another feature of this prototype that has been turned to good account is the pair of compressors on the smokebox door. They hide a large hole in the smokebox door of the model; this provides all the ventilation for the burner, so the stack has to deal with the steam exhaust only, thus avoiding any condensate leak getting to the flue. This loco also has a Vanderbilt tender, which is much more of a problem to produce than the rectangular type. | |||

Revision as of 22:27, 24 February 2018

From Zen.co.uk

Reprinted from the November 1973 Model Railways

A. A. Sherwood records considerations necessary when producing really small scale steamers, like eight-coupled wheelbases of less than one inch!

The Problem

In these days of affluence live steamers seem to be getting bigger and bigger. Only a few decades ago 5 inch gauge was really big and most enthusiasts were content with 2½ or 3½ inch gauges. O gauge was called watchmaking and anything smaller impossible. I rather suspect that many of the model loco fraternity are not really model makers at heart but would prefer to work in 4 ft 8½ inch gauge if they could afford it. Being a perverse individual, I have progressed in the opposite direction down through 00 (now called HO), 000 (now called N), to something a little smaller than the recently introduced Z gauge.

Many of my previous efforts were in the toyshop tradition - pot boilers and methylated spirit wick lamps, which were quite effective down to 000 gauge provided one excluded all draughts and could put up with the unsavoury smell of the products of incomplete combustion. It was clear that a new approach was necessary to get down to smaller live steamers. The boiler and firing are the major design problems; the chassis may look much more complicated, but provided the workmanship is sufficiently accurate it will work. The boilers in the three locos to be described are basically the normal loco boiler design taken to its logical limit. In full size we have hundreds of tubes; in 5 inch gauge a dozen or two, so the limit we can go to is one tube, or flue. Now this flue doesn't have to be circular, and it doesn't have to be completely surrounded by water. The basic concept becomes a circular shell with a horizontal division; the top half contains water and the lower half forms the flue. To fire such a boiler, we need a stiff horizontal blowtorch type of flame. Butane, now readily available in a wide variety of packs, is the obvious fuel choice - ask anyone who has had experience with the tantrums of small petrol or paraffin blowlamps. The burner seemed the first item on the largish 'problems to be solved' list.

The Burner

The ordinary Bunsen tube is a fairly simple proposition - in the normal sizes. A high jet velocity is essential to get a stiff flame, and some rough and ready calculations showed that the rate of gas flow (i.e. cubic inch per minute) would be minute. I had to think of jets of the order of a "thou" diameter. Experiments with plain Bunsen tubes were disappointing; they had to be very long to get a stable flame - so long, in fact that the end near the jet got blocked with ice due to the cooling effect of the expanding butane! No amount of baffling could be found to make a sufficiently short burner tube which worked. After all, it has to be housed in the tender, and even the "coast to coast" tenders of the Pennsylvania R.R. are of finite length. The solution to the problem required some rethinking. The final outcome can best be described by reference to fig. 1. The volute coil of nichrome wire screwed into the end of the Bunsen tube is the essential ingredient. My analysis of the action is as follows. The wire coil leaks a little of the gas-air mixture at the sides, which produces a fuzzy "halo" of flame round the outside of the coil rather like a "doughnut" (or "donut" if you prefer that spelling) about 4 inch diameter. This keeps the projecting end of the coil at a dull red heat and stabilizes the main flame formed by most of the gas-air mixture which issues from the outer end of the volute coil. There is also probably some effect on the turbulence and mixing due to the shape of the internal surface of the coil, and possibly some catalytic effects as well. Anyway, it works provided that one is very careful to avoid mechanical damage to the delicate coil, and the whole burner is short enough to go in the tender and leave room for the butane tank as well. The capacity of the latter only needed to be about 0.1 cubic inch to run the burner for over 15 minutes. The burner is readily controlled by a needle valve - in fact this is the only control used on the locomotives. Details of the production of the tiny jets will be covered later in this article.

The Choice Of Suitable Prototypes

Having proved that a satisfactory burner could be made, the boiler was the next item of research. It seemed that a suitable prototype should have the following characteristics

- 1. A tender at least 35 foot long with fairly high sides to house the burner and fuel tank

- 2. A large diameter boiler, but not too long, since the prospects of blast pipe induced drought were not thought to be good.

- 3. Big cylinders

- 4. Big firebox

- 5. Not a 4-wheel leading bogie.

Since you don't get fat boilers unless the loading gauge is high and wider the obvious place to look is the U.S.A. My first choice was the Delaware & Hudson 4-8-0. (Fig. 2). This satisfied items 1, 2, 3 and 4 of the above list very well. As is seen from the cross section through the second coupled axle, the boiler (or to be precise the casing) is very wide and high. The two front L.P. cylinders are whoppers - 33 inch bore. The H.P. and L.P. cylinders at the back wouldn't have any function in the model. The prototype also had two more cylinders - in the booster on the rear tender bogie - hence the coupling rod on the latter. It did have a 4-wheel leading bogie, but then one doesn't expect the designers of full size locos to consider the model engineers requirements.

The D. & H. also had some 2-8-0 locos with similar boilers, but all these were lopsided two cylinder compounds, with much smaller H.P. cylinders and also external linkage valve gear, whereas the 4-8-0 has poppet valves with little external evidence thereof. I didn't feel inclined to tackle a full external valve gear for my first loco in this scale. In Fig. 2 I have also shown in outline the other two locos I have built in this scale. I will leave it as an exercise for the reader to decide how well or how badly they comply with the five items listed above. The Pennsylvania K5 is the one with [Caprotti valves Caprotti valves] with no valve gear visible externally, which gave me a chance to try internal oscillating disc valves on the model. The trio cover the range from drag speed freight to express passenger steam traction.

Boiler Design

The D & H boiler for the model has the cross section shown in Fig. 2. It looks a poor shape for a pressure vessel but the steam pressure required is low - 15 p.s.i. is more than enough for these midgets. Rough calculations show that the water capacity should be enough for about half a mile run. This assumes no leaks, no condensate waste when starting and dry saturated steam. Even if we allow for wastage of 90 per cent of the water, we should still get a run of about 250 foot. That's about forty laps of the 2 foot diameter test track I had constructed - the track was turned on a lathe with a 4 foot diameter faceplate. Anyway, I don't contemplate going in for any of the now popular efficiency tests with these models!

All the water "drums" of the boilers were made of 0.01 inch thick phosphor bronze sheet, which does not go as soft as copper under the heat of silver soldering. Vertical stays at about 0.4 inch centres support the floor of the drums, and cross stays of tubular form are inserted to take the handrail supports. The lower "pan', which forms the sides and bottom of the flue and firebox is made from 0.012 inch nickel silver sheet. The D. & H firebox floor is rather high, as it has to clear the tops of the driving wheels. The other two have the advantage of lower floors, giving more volume for combustion. The lower pan and water drum meet at the level of the footboards. It will also be seen from the cross sections that extra flue space has been "sneaked" in the last two locos between the coupled wheels and above the axles. This extra flue area is quite significant in the case of a loco with large drivers (80 inch diameter) such as the K5. The main steam-pipe (0.035 inch hypodermic tubing) is connected to the back-head by a barrio union (see Fig. 3). This union is designed to avoid the drilled bolt used in the usual form of banjo union. I don't like drilling long small holes in stainless steel. A 6 inch length of hypodermic tubing in the firebox and flue serves as a steam drier.

General details of the models

| Whyte Configuration | 4-8-0 | 2-8-2 | 4-6-2 |

|---|---|---|---|

| Cylinder bore (inches) | 0.12 | 0.10 | 0.085 |

| Cylinder stroke (inches) | 0.12 | 0.12 | 0.12 |

| Driver diameter (inches) | 0.262 | 0.280 | 0.333 |

| Rigid Wheelbase (inces) | 0.95 | 0.90 | 0.72 |

| Total wheelbase engine (inches) | 1.74 | 1.95 | 1.90 |

| Total Wheelbase, engine & tender | 4.15 | 4.28 | 4.08 |

| Overall length, engine & tender | 4.60 | 4.75 | 4.50 |

| Type of valves | piston | piston | disc |

| Valve gear | eccentrics | Walschaerts | eccentrics |

Features Common to all Three Locos

All the coupled wheels are of nickel silver, the spokes, bosses and balance weights being formed by cold pressing with a hardened steel die. It requires about six anneals to get the impression to full depth. The flanges are 0.017 inches deep and the treads 0.035 inches wide. Main axles are 0.055 inches diameter hardened silver steel, with wheels press fitted. The main frames are of brass, split on the horizontal centre line. This allows of dismantling without disturbing the press fits and also adjustment for wear. The cab sides and roof are silver soldered to the lower pan of the boiler assembly, and serve to hold down the water drum at the rear with endwise freedom to allow for thermal expansion. All cylinder blocks are of brass with hardened steel liners pressed in for cylinders and piston valve sleeves, except in the case of the P.R.R. 4-6-2 which has oscillating disc valves. The rear cylinder covers are also in hardened steel and press fitted. All methods I have tried of packing to obtain steam tightness have been useless because of frictional resistance; consequently I am relying on lapped fits in hardened steel for piston, piston rod and piston valve sealing. Some leakage is evident, but the frictional resistance is very small. The exhaust has to be taken up to the level of the top of the stack, otherwise drops of water form in the latter and stay there by surface tension. Therefore there is no induced draught as in the normal live steamer; fortunately, the burner is quite capable of inducing its own draught.

Each loco has an identical burner (see Fig. 1.) The Bunsen tube is of stainless steel, with air holes so big that the tube is almost separated into two parts. To get proper combustion in the tender, the floor has had to be cut away to allow unrestricted air flow. The tiny jets presented quite a problem. The final solution was to drill from the back of the jet body to within 0.01 inches of the front face with a no. 80 drill, and achieve the final break through with a needle ground to the form of a long triangular pyramid with an included angle of about 5°. With care, I found that it was possible to grind the needle and preserve a "point" of the order of 0.001 inches thick. The drilling was performed in the watchmakers lathe with a lever feed tailstock, with the depth stop set to advance the drill one "thou" at a time. The resultant holes were deburred at the business end with a fine oilstone and examined optically. They looked reasonably good, and performance in the burner was tolerable, but it was evident that they would work better if I could get them a little smaller. I then tried compressing the jet tube by forcing it into a coned hole in a piece of hardened steel. This gave an excellent flame when tried in the burner; I haven't bothered to measure the hole size but I'm pretty sure it isn't much over a "thou" diameter at the small end.

Now, as all users of small jets know, blockages will occur, so a pricker is required. Pricking from the outside of the jet was obviously a very delicate operation, and it doesn't sound very sensible to push the muck back into the larger end of the hole. The best solution seemed to be to unscrew the whole burner, jet and all, and introduce the pricker from the back it's easier to get it started in the no. 80 hole. The first pricker was a long coned point ground on a needle, but this stuck in the jet and the tip snapped off and stayed there. So now I use a piece of piano wire with a log coned point; it's hard enough to do the job but not so brittle as the needle. Since the jet hole is several diameters long, there is little danger of increasing its size when using the pricker; a short jet hole is easier to make, but also very much easier to enlarge when pricking. During this operation, I use a 10 magnification eyepiece to see the tip of the pricker emerge from the small end of the jet.

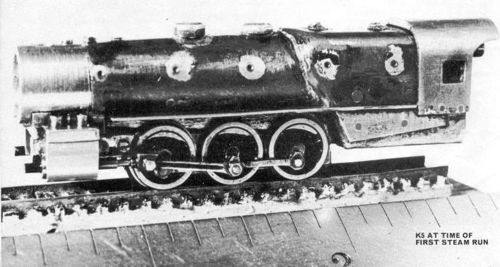

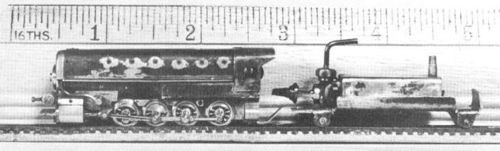

The D. & H. 4-8-0

In this model, the first of the trio, the ports in the valve sleeve are drilled 0.02 inch diameter the piston valve having a diameter of 0.05 inch and 0.05 inch travel. On testing the valve timing on compressed air and making the final adjustment by pressing the valve sleeves a few "thou" either way axially in the cylinder block (not the best traditions in engineering, I admit) the best compromise i could get wasn't very good. Still, the chassis buzzed round merrily on less than 10 p.s.i. so I let well alone. The front cylinder covers are of very uncommon design in this model; the usual ring of studs holding the lid on is just not "on" in this scale. Also, as the cylinder block stretches right across the loco, the main frames couldn't pass through from back to front, so there was nothing to hold up the front pilot beam! One doesn't worry much about such trivialities when getting a new design to work for the first time. The pilot beam isn't functional, but the cylinder covers are. Why not make the pilot beam support and both cylinder cover in one piece? This idea solved both problems, as I managed to find room for four bolts to hold it on somewhere between the cylinders and valve chests that showed their (erstwhile) open ends on the front face of the cylinder block. The steam connection to the cylinder block is via the banjo union on the left side of the model just above the crosshead; this is visible in the photograph showing the state of progress just after the first run on the track.

The GN 2-8-2

This model was started after the D & H 4-8-0 had been completed with enough frills to make it look like a loco - or perhaps I should say like the prototype, as there are probably many of the loco fraternity who would deny that the prototype ever looked like a locomotive. The G.N. 2-8-2 was the biggest Mikado ever made; the loading gauge on this railway is very high and wide and that means handsome when working in small scale. The overhang behind the rear coupled axle is so long you wouldnot believe it without proof. It's more than many locos with 4 wheel trailing trucks had. In fact the overall suitability seemed so good that I freely forgave the designer for putting Walschaerts valve gear on it, and got down to the task of designing a linkage that would work in this scale and deceive all but the most critical of observers.

There are so many joints in linkage where lost motion can occur that the aim of the design is to minimise the number of joints. The first idea was to drive the valve by one link from the return crank to the valve direct. It might be possible to bend this link in a cunning manner behind the expansion link, but on investigation this couldn't be made to look realistic even to Mr Magoo. Adding two more joints solves the problem however; the gear is conventional from return crank to expansion link, and the radius rod pivots from a point fixed in the expansion link direct to the valve. The union link and combination lever are frills added later, are not functional. The phasing of the return crank can be set to give any cut-off desired and the main length of the radius rod doesn't have to go direct from pivot to pivot; it can take any course we like to deceive the observer that he is looking at the real thing in motion. I began to get very enthusiastic about the whole sneaky business! Just as well perhaps, as I found enthusiasm very important when I got down to detail design.

The outside faces of the drivers take up a width of 0.31 inches. The loading gauge is 0.55 inches wide. Within the space of 0.2 inches on each side one has to get in the connecting rod, coupling rod return crank, eccentric rod and the nut to keep the latter from coming off. That means an average thickness of 0.024 inches per item - or less if some clearance is deemed desirable. How does one make a return crank so thin with positive location? Make it in one piece with the crankpin and pressfit to the wheel, remembering to put the coupling and connecting rods on first! O.K. if you are so sure that you don't want to take it apart again - and I usually find I have to. My final solution is shown in the exploded sketch (Fig. 4). The crankpin is 0.06 inch diameter and the c/sk head screw that secures the return crank is threaded 0.032 inch diameter. I apologize for the horrible sight of the screwdriver slot, but since the screwhead cannot be allowed to protrude from the return crank no other solution seems possible. The crankpin is, of course press fitted to the driving wheel.

Remembering the poor valve events on the 4-8-0, due to the wayward tendencies of small drills, I cut the ports in the valve liners with a 0.01 inch thick saw cutter. Not the usual commercial article, which in this thickness wanders as badly as small drills. I used a home made one like a small woodruff cutter with integral shank 1/8 inch diameter, the cutter being 3/16 inch diameter silver steel, hardened and tempered, random spaced teeth, no top rake, side or front clearance - all against the book - and the result was ports to within 0.0061 inch precision in spacing and width.

The final adjustment to the valve setting is by screwing the crosshead in or out. There is no room for a locknut here, but the threads are tight enough to stay put - if they weren't, a small smear of Araldite, or even paint would do the job. Another feature of this prototype that has been turned to good account is the pair of compressors on the smokebox door. They hide a large hole in the smokebox door of the model; this provides all the ventilation for the burner, so the stack has to deal with the steam exhaust only, thus avoiding any condensate leak getting to the flue. This loco also has a Vanderbilt tender, which is much more of a problem to produce than the rectangular type.