Leaf springs

Jump to navigation

Jump to search

See also Spring steel and Some Notes on Springs.

Dick Morris wrote on Chaski.org:

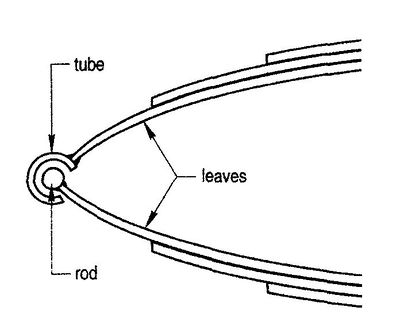

- In Jeff Smith's arch bar truck thread I asked how the eyes are made on the end of elliptical springs and was referred to a December, 1997 Gail Gish article in Modeltec. Gail silver soldered a rod on the lower spring. To the upper spring he soldered a tube which was later slitted. No heat treating was specified after the silver soldering.

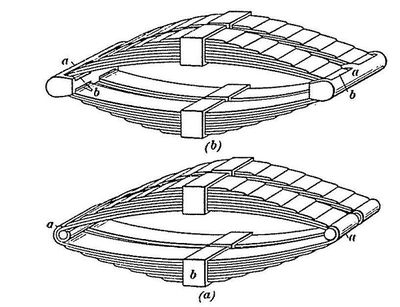

- I dug through my library and found a drawing comparing two styles of ends. This came from an old text.

- Some time back I made a pattern for the end casting but wasn't able to get the pattern to pull without breakaway in the recess for the springs. The next photo shows the original wooden split pattern, the urethane copies on a match plate, and the unsuccessful castings. I'm in the process of reworking the wooden pattern so I can make the piece using lost wax.

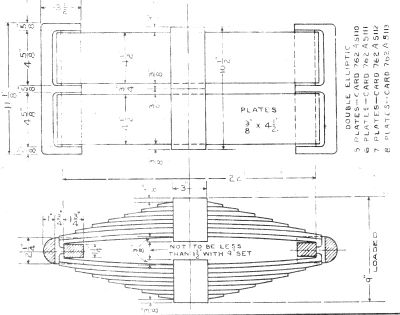

- I found a couple of good prototype drawings. One is for a 1906 vintage ALCO tender truck. Something that I wasn't aware of when I made the pattern above was the tab on the end of the spring. I had wondered how to avoid having the castings pop off, now I know. I'm going to need to modify my pattern to include the recesses for the tabs.

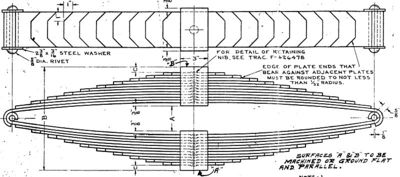

- The final drawing is from a circa 1945 PRR tender Included because it clearly shows their design with some dimensions.

Dave Bortz posted on Chaski.org:

- I make these in lost wax steel for six wheel passenger car trucks... They aren't springs, but they look nice... The post is 1/2" wide x 3/8" thick to fit the passenger car truck bolster and plank.

Dave "fly5150" posted on Chaski.org:

- Here is a spring separator we just got back from the foundry. I will be using these on the next round of 1.6 scale Blomberg trucks, but they can also be used on other locos and some passenger cars. I bolted them on with some 2-56 screws, but final install will be with 3/32" Rivets. Little details like this make all the difference.

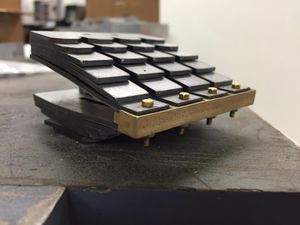

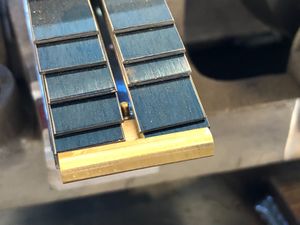

Jack Bodenmann posted on Chaski.org:

- Here are a couple of spring ends. They are a simple matter to machine up as a strip if you have an angle vise for the mill. There is a little pin as you can see in the second photo that keeps them from wiggling out. For jobs like cutting out equalizers I will often use a brand new bandsaw blade. Also my bandsaw blades all start out as brass cutting blades. Once a blade is used for steel it looses its freshness and doesn't work well for brass. Sometimes it's a pain to change blades back and forth for steel and brass but I think it's worth it. Same goes for files. They all start out as brass files with red handles and when they get a bit dull the red handles come off. I also have separate drawers in the work benches for brass and steel files.

- Happy Model Building

- Jack