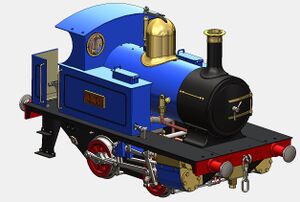

LBSC's Tich

Considerations needed to model Tich (and build it)

Jim Mullner

January 2022

I was admiring the article by Don Althouse on LBSC's Virginia. I would also like to share some of the SolidWorks activity I have completed on the LBSC trains.

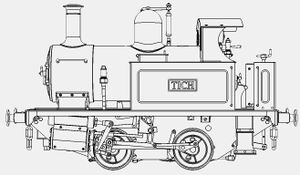

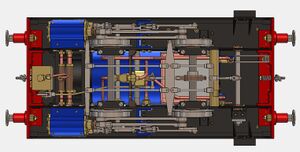

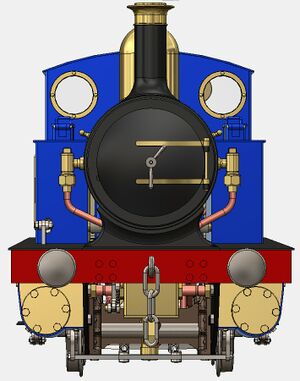

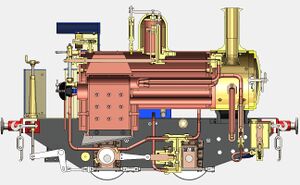

I was able to completely model 3-1/2 gauge Tich and animate the result, as shown below.

I have found there are a number of small but important errors in the details given in the Model Engineer. If folks knew about them and had access to these 3d models it would help them have a much better experience building.

General Tips

- Settle on a standard for steam unions. This mainly includes steam cones and union nuts but could also include union cones. See my table of standard dimensions based on tubing diameter. It’s important to note the discussion in Model Engineer by LBSC is not always consistent when it comes to what to use, so pick based on tubing diameter. See also Union Nuts & Fittings.

- Make sure you are familiar with British Association threads (BA Threads). These are important for small scale building like this. See my chart for modeling sizes I eventually settled on. For modeling purposes, I kept the female threads at nominal and ran the male stud at about 95% on the diameter, but I kept the pitch the same for both.

- Make sure you are familiar with sheet gages and wire gages and pick accordingly. Sometimes the values are given but it’s not clear always between steel, copper, and brass. And there is also the difference between American gage and British gage. See my chart for some references.

Specific Tips

Now for the specific issues with Tich.

- I do not believe all the details needed to build Tich are present in various issues of Model Engineer that can be easily obtained. A great source for information is found here: http://www.john-tom.com/LBSC/TichSm.pdf

- Another great source of info is found here (the internet archive): "TICH - The Smallest 3-1/2 inch Gauge Engine Yet by L.B.S.C.", The Model Engineer

- I purchased a book called Simple Model Locomotive Building Introducing LBSC's TICH by Martin Evans. This book is just a compilation of the various Model Engineer articles that were published back in 1949! Visit AbeBooks

- You will need to select a few options up front to decide on things like "small boiler" or "large boiler". Also, there is a choice between two safety valve styles. I modeled the "spring balanced safety valve" and used the "large boiler" as they appeared more interesting to model.

- Other options must be selected for which type of valve gearing you use. I modeled the Walschearts' style valve gear as it was more interesting.

- Make sure to read the "1959 post-mortem review" by LBSC in Model Engineer - this can be found in the "johntom" site PDF if you actually plan on building Tich. There is where he covers issues with excessive oil and water supply. The model presented here has these issues addressed in various ways.

- I have not brazed a live steamer boiler, but I do understand that some of the aspects of LBSC's design may not pass modern test standards so if you plan on building this to run at your local club make sure to learn their codes for boiler design and adapt as needed.

- Be aware that LBSC does not show halite gaskets even though they are later discussed – so you must plan ahead for where metal stock will be removed to accommodate them.

Drawing Corrections

The information given in the Model Engineer articles is general pretty good but there appear to be issues in a few spots. Namely things will interfere if built to the dimensions shown. Here are a few of those areas that I was able to discern by modeling TICH in Solidworks.

Making small corrections as noted below allowed the radius rod and eccentric rod to complete their movements without interfering with the other valve gear parts. Perhaps TICH was laid out correctly for the loose eccentric valve motion option and not for the Walschaert valve gear option but this brings me to a concluding point.

- If you are actually going to build an LBSC design make sure to layout the entire project using 2d or preferably 3d CAD software to avoid nasty surprises during real assembly and testing.

Please use the 3d model files presented here to check your work and review the details provided in the Model Engineer magazine articles. I recommend reviewing the original instructions and then reviewing the 3d model to confirm.

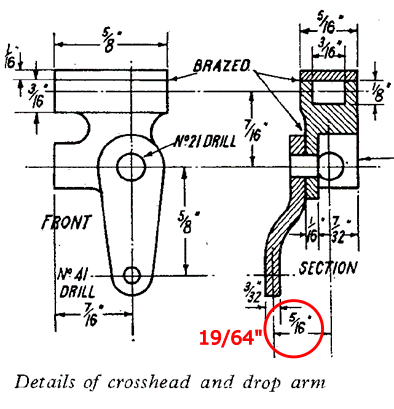

Crosshead and Drop Arm

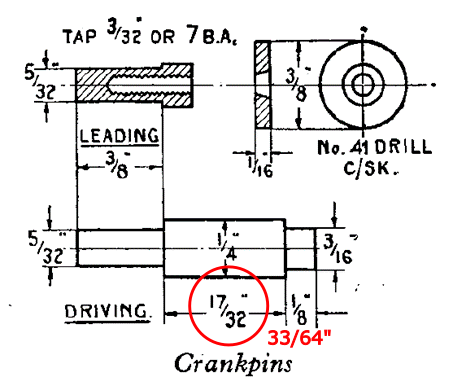

Crankpins

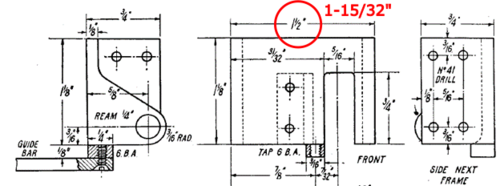

Gear Frame

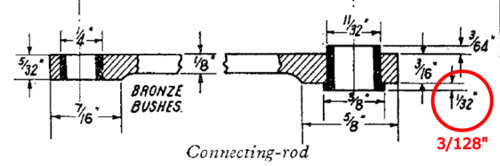

Connecting Rod

Brake Hanger

The brake hanger must have more curvature to avoid interferences and permit the brake shoe to sit properly. See 3d model for details.

Steam Ports

The steam ports in the cylinder must be planned out. This leads to the bolt pattern for the covers being rotated 25 degrees off vertical to accommodate. See 3d model for details.

Snifting Valve

The pipe for the snifter valve can’t come out the front of the superheater connection because it will interfere with the chimney. Have it come out the side – See 3d model for details.

Documents

- Tich 3D Model in Parasolid (X_T) Format

- Tich 3D Model in STEP Format

- The 3d model can be opened and viewed using this free viewer: https://www.edrawingsviewer.com/frequently-asked-questions

- British BA Threads

- Sheet Wire Gauges

- Steam Unions

- Union Nuts & Fittings

Gallery

External Resources

- Animated video of TICH by Jim Mullner: https://www.youtube.com/watch?v=0vOMmAbwMjE

- Castings for TICH components: https://www.ajreeves.com/tich.html

- An excellent visual overview of a TICH built by a person in France: https://www.youtube.com/watch?v=9A1lBWsIsKc

- Another great visual overview of a TICH: https://www.youtube.com/watch?v=LW0gqczKsAk