Getting Stuck on Dead Center

by Jeff Frost

29 December 2017

Dead center is at the extreme end of the piston’s stroke when the force through the main rod is in line with the axle center line so the piston force doesn’t have any rotational effect/torque on the drivers. To combat this, the crank pins on steam locomotives are offset by 90 degrees so when one side is on front or rear dead center the other side has full power/torque. Despite this steam locomotives can still get stuck on dead center and not move in the desired direction.

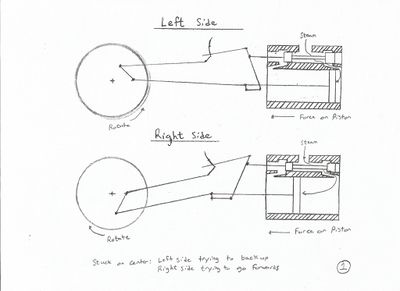

Sometimes the weight of the train is too much for the force on a single piston to move. Other times the force on the pistons is working against each other with one side trying to go forward and the other side trying to go backwards.

Lead is defined as how much the valve has uncovered the steam port in the valve chamber when the piston is on dead center. The valve opens before the piston reaches dead center (point of pre-admission is when the valve opens the port) and the steam cushions the piston as it slows down to a stop before it reverses direction.

If a locomotive stops before the piston has reached dead center, the valve could be admitting steam to piston bore and the force could try to rotate the wheel the opposite direction. The sketches I did are of the Walschaert valve gear as it was easier to draw.

If the left side stops before the piston reaches front dead center, steam can be admitted to the front side of the piston and push the piston back. Since the crank pin is before/above dead center, the force on the crank pin will try and rotate the wheels backwards. However on the right side the crank pin is near full torque for moving forwards and the steam is admitting steam to the front side and the force on the piston will rotate the wheels forward. Due to a heavy load or low pressure, the force from the right side to move forwards might not overcome the force from the left side to move backwards. The throttle can be wide open, cylinders up to full boiler pressure and there the locomotive stands.

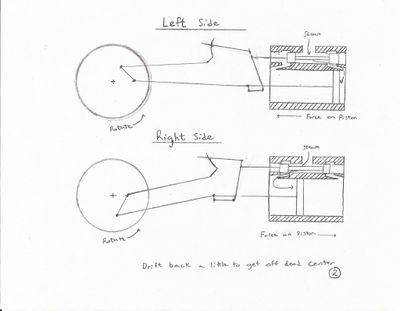

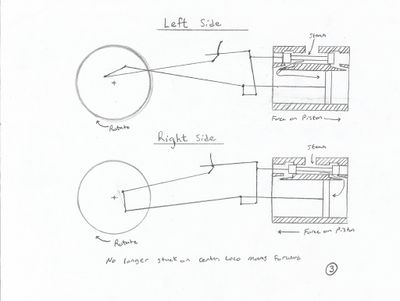

To get unstuck, the locomotive needs to move backwards (the opposite direction that is desired) a little bit to get the left side away from dead center. Draining the cylinders of the steam pressure is helpful but not always able to be done. With the throttle shut the valve gear is reversed slightly to the rear of center and the steam pressure on both pistons will start the locomotive backwards. Once the locomotive has drifted back a little bit and slack in a few couplings has been taken, the valve gear is put back into forward and throttle opened. The pistons are both away from dead center and the force on both pistons are causing the wheels to turn forwards.

The locomotive doesn’t need to move very far (if moved too far, the locomotive can get stuck on another dead center or cause a lot of slack action in the train). The Johnson bar/reverse bar doesn’t need to move much past center. If moved to the extreme opposite end of the quadrant the locomotive can move quickly and too far as well as taking more time to move back to the desired direction and can cause a lot of slack action.

Some people like to give a slight set on the automatic/train brakes while doing this and others don’t. The reason for giving a slight set on the automatic brake is to give some resistance to help keep the train from getting away from you. The reason for not using a slight set when taking up slack is that when the brake is released, it doesn’t release immediately but takes time so when the valve gear is put back into the desired direction and throttle opened, more power is needed due to the resistance from the brakes and it can be possible to get stuck again on dead center (weak spot in the power) more easily. Since the locomotive only needs to move a few feet, carefully controlling the Johnson bar/reverse bar can gently bump into the train and take up slack in a couple of couplings and stretch it back out without being rough for the riders/cars.

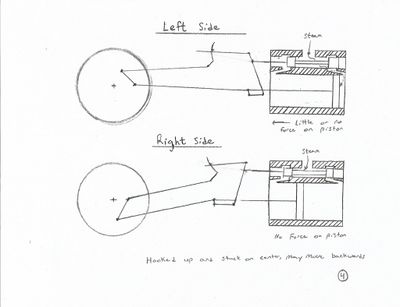

Stephenson valve gear, unlike Walschaert valve gear, is a variable lead valve gear. When set up as open rods, as on a steam locomotive, the lead increases until the valve gear is in center. In the USA the common practice is to set the valves blind when in the corner, meaning the valve has not uncovered the steam port at dead center. The wheels and valve need to rotate to uncover the port. This means that when on center, steam is only being admitted to one cylinder. If the pull is too much, the force on a single piston won’t be enough to move the train.

If the valve gear is hooked up high a locomotive can get stuck on center. When one side is near center, the valve on the other side could already have closed the port to the cylinder; this means that the piston on the side that is set up for the most torque does not have any steam acting on it. The side near center might not have any steam being admitted to it (the locomotive will not move under its own power) or might have a little steam being admitted. If just before the dead center for the desired direction of movement (forwards in the sketch), the steam will push on the piston and cause the drivers to rotate the opposite way (backwards in the sketch).

Dave got stuck in center in this video. The valve gear was hooked up near center and she got stuck in center. That is why when he opened the throttle she didn’t move and he had to rock back and forth to coax the locomotive off of center.

<videoflash>ck4xQSe4C9U</videoflash>

If the valve gear is poorly set or worn, the valve events can be poor/off and the locomotive can be stuck on center easier.