Coupling Couplers

Coupling Couplers

by Harry "Scorcher" Bean

LOCO News, Volume 18, No. 1, January-February 2005

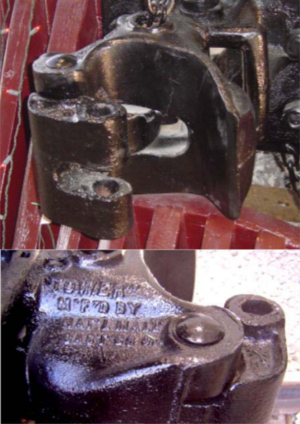

After the Civil War, a number of automatic couplers were invented to replace the old link-and-pin couplers. One of them was the Janey Automatic Coupler introduced in 1879. Because link-and-pin systems remained in general use, many of these early automatic couplers, while not compatible with each other, had a notch in the center of the knuckle for couple to a link and a vertical hole in the knuckle for the pin to hold the link. Finally, in 1888, the Master Car Builders Association (MCB) adopted the contour lines of the Janel patent as the standard for U.S. railroads. The MCB thus ensured that all couplers in use would be able to couple to each other. Then in 1911, the MCB Coupler Committee took the next step and asked the manufacturers to cooperate in the development of a coupler in which all the parts would be interchangeable as well. This resulted in a new standard design, the Type D, being adopted in 1916. In 1932, the Type E coupler was adopted. This improved version had no parts interchangeable with the Type D and is still the most widely used U.S. coupler.

So, here it is 72 years later and, oh, how nice it would be if the manufacturers of our 1-1/2 inch scale equipment would follow suite and adopt a standard coupler contour. The inability of one brand to couple to another brand is an inconvenience, at best. However, it becomes downright annoying during an operating session when making up trains and cars supplied by many owners. And then there is the matter of safety. While some couplers may couple initially or appear to couple, they tend to separate at inopportune times during the run. How about it, Live Steam manufacturers? While your parts would not have to be interchangeable, you could achieve true coupler compatibility throughout the hobby if you would adopt a standard contour!

While we wait for the happy event, equipment owners can themselves help mitigate the problem. First, filing or grinding the knuckles and/or the knuckle pockets goes a long way toward improving compatibility. Second, spraying couplers with WD40 or graphite before each meet makes life much smoother for the brakemen. and speaking of brakemen, if the open knuckle of one coupler won't couple with the closed knuckle of the other, try reversing the open and closed knuckles. Also, brakemen should ALWAYS carry a small pocket-clip screw-driver to be used to coax a latch by "tickling" the knuckle of a reluctant coupler.